Preparation method and application of carbon nanofiber-bimetal composite catalyst

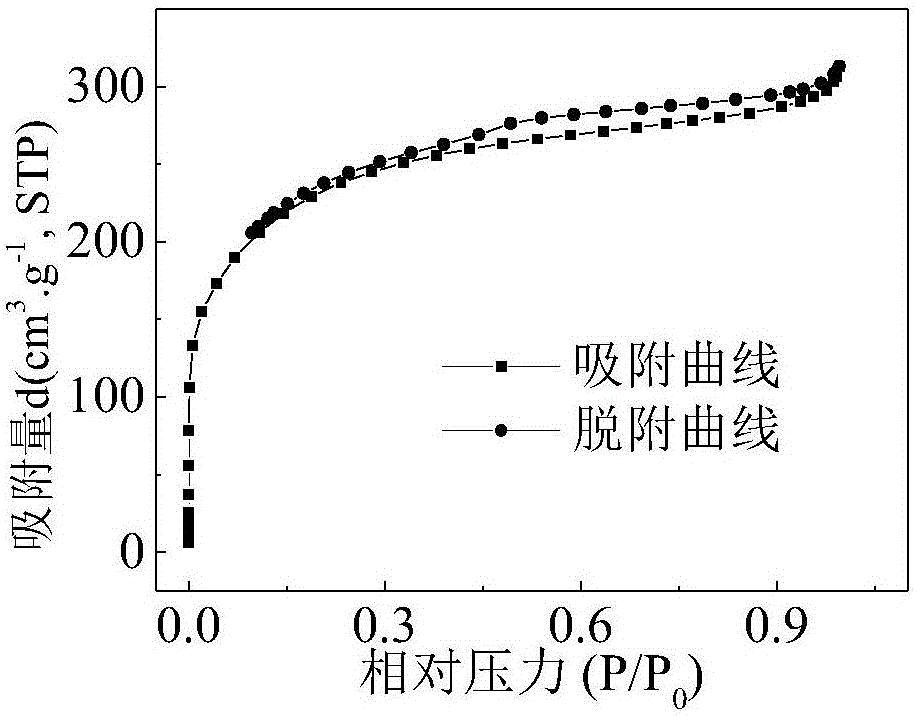

A composite catalyst, nano carbon fiber technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. problems, to achieve the effect of reducing the preparation cost, improving the conversion rate and high pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0026] (1) First weigh a certain amount of magnesium sulfate and dissolve it in the acetic acid solution, then weigh 3~5g lignin and mix, heat and stir the above mixed solution, set the end temperature to 60~80℃, and add it with a needle during the stirring process 3 to 5 mL of 10wt% polyvinyl alcohol solution. After continuing to stir for a period of time, turn off the heating device, naturally cool down to room temperature and transfer to the syringe;

[0027] (2) Spinning the above-mentioned spinning solution on an electrostatic spinning machine, and then combine the nanofibers with Ni(NO 3 ) 2 Mix and soak overnight and evaporate to dryness. Then wash until neutral and dry.

[0028] (3) Put the above-obtained dried composite in a horizontal tube furnace, at an air flow rate of 150mL / min, and a heating rate of 0.3~1℃ / min, the temperature will be increased to 200~250℃, and then the temperature will be pre-oxidized for a period of time. , After the temperature drops to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com