Monodispersed iron-based catalyst for Fischer-Tropsch synthesis as well as preparation method and application thereof

An iron-based catalyst and Fischer-Tropsch synthesis technology, applied in catalyst activation/preparation, carbon compound catalysts, catalysts, etc., can solve the problems of low selectivity of long-chain α-olefins in catalyst stability, reduced activity of iron nanoparticle catalysts, etc. , to achieve the effect of improving activity and α-olefin selectivity, easy to control the degree of carbonization, and avoiding difficult-to-reduce components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

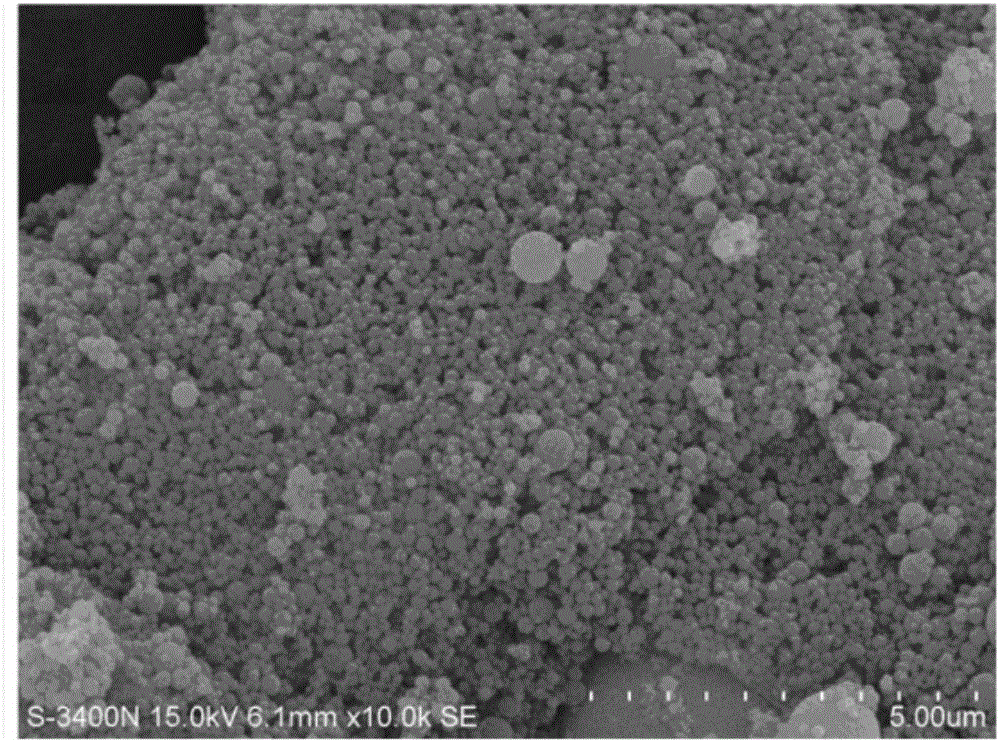

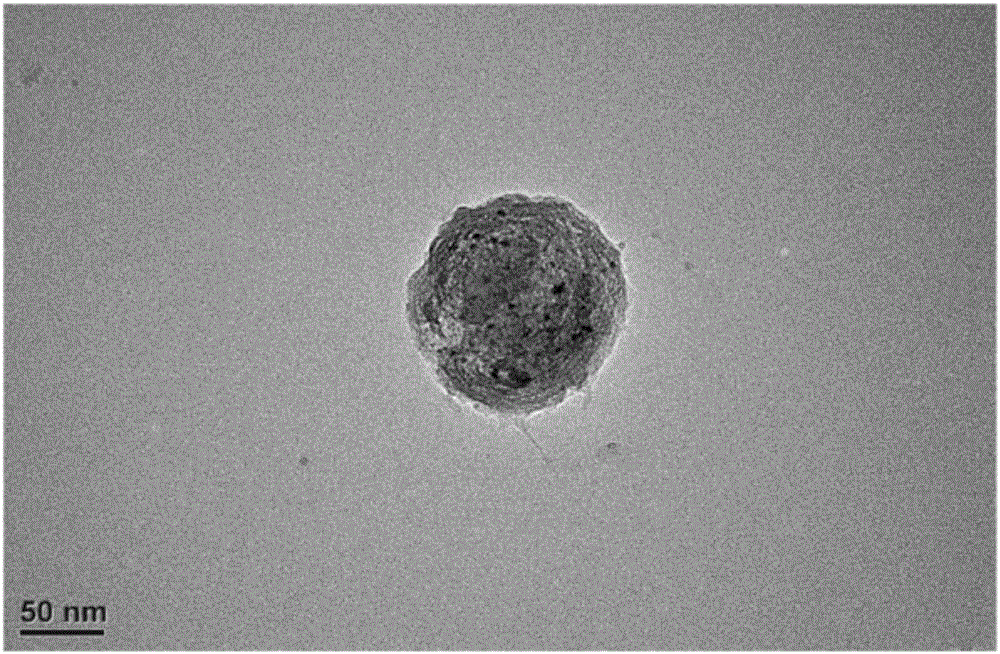

[0033] Weigh 1.22 g of dodecylamine, add it to 10 ml of ethanol and 90 ml of water and stir at room temperature for 1 h; then add 0.59 g of iron nanoparticles and 8.16 g of tetraethylorthosilicate; 2 and heated to 40°C and stirred for 24h, at this time CO 2 The pressure is 1.0MPa, after the reaction is over, cool and release CO 2 The obtained solid was washed with water and suction filtered several times, dried overnight, and the powder obtained by drying was roasted in a muffle furnace at 500 ° C for 5 hours; finally, it was pressed into tablets and sieved to obtain Fischer-Tropsch monodisperse iron with a Fe content of 20 wt%. Based catalyst (20wt%Fe@SiO 2 -CO 2 -1), with CO 2 The increase of catalysts from discs (such as figure 1 Shown) stacking transformed into the iron-based catalyst of the present invention of uniform spherical particles (such as figure 2 As shown), the iron-based catalyst wraps iron nano-iron particles in mesoporous spherical silica and distribute...

Embodiment 2

[0037] Weigh 0.5 g of formamide and add it to 90 ml of ethanol and 10 ml of water and stir at room temperature for 1 h; then add 0.34 g of iron nanoparticles and 5 g of tetraethyl orthosilicate; 2 And warmed up to 45°C and stirred for 22h at this time CO 2 The pressure is 4.0MPa, after the reaction is over, cool and release CO 2 The obtained solid was washed with water and suction-filtered several times, dried overnight, and the powder obtained by drying was roasted in a muffle furnace at 560°C for 4.5h; tableted and sieved to obtain a Fischer-Tropsch synthesis monodisperse iron base with a Fe content of 20wt%. Catalyst (20wt%Fe@SiO 2 -CO 2 -4), the particle size of the carrier silica particles is 155nm, and the mesopore diameter of the carrier silica is 3.7±0.4nm.

[0038] Fill a pressurized fixed bed reactor (Φ10×500mm) with 1.5ml of the above-mentioned catalyst of 60-80 meshes, and perform temperature-programmed reduction in pure hydrogen. The reduction conditions are: t...

Embodiment 3

[0041] Weigh 2 g of piperazine and add it to 10 ml of ethanol and 90 ml of water and stir at room temperature for 1 h; then add 1.45 g of iron nanoparticles and 20 g of tetraethyl orthosilicate; 2 And warming up to 35°C and stirring for 26h, at this time CO 2 The pressure is 6.0MPa, after the reaction is over, cool and release CO 2 The obtained solid was washed with water and suction filtered several times, dried overnight, and the powder obtained by drying was roasted in a muffle furnace at 540°C for 5.5h; finally, it was pressed into tablets and sieved to obtain a Fischer-Tropsch synthesis monodisperse with an iron content of 20wt%. Iron-based catalyst (20wt%Fe@SiO 2 -CO 2 -6), the particle size of the carrier silica particles is 160nm, and the mesopore diameter of the carrier silica is 4.6±0.4nm.

[0042] Fill a pressurized fixed bed reactor (Φ10×500mm) with 1.5ml of the above-mentioned catalyst of 60-80 meshes, and perform temperature-programmed reduction in pure hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com