Ionic liquid modified urate oxidase enzyme membrane and preparation method thereof

A urate oxidase enzyme membrane and urate oxidase technology, applied in the field of urate oxidase enzyme membrane and its preparation, can solve the problems of restricting enzyme membrane type electrochemical uric acid sensor, short storage and service life, poor anti-interference ability, etc., to achieve The effect of maintaining and promoting protein activity, improving electrical conductivity, and good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

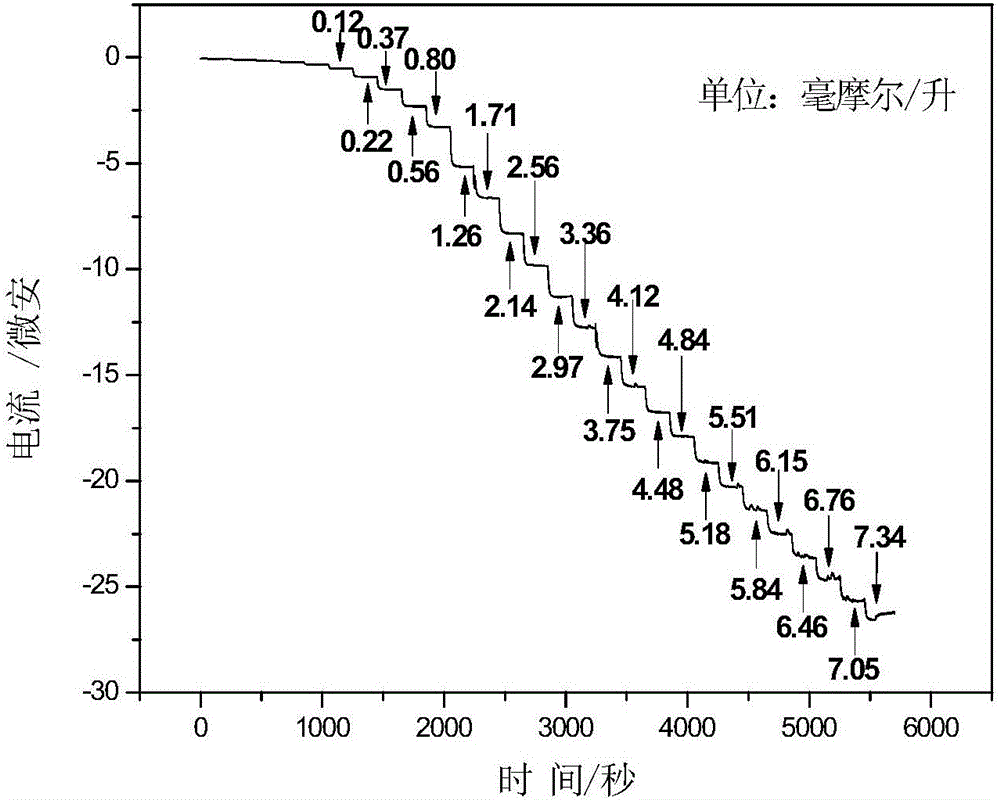

Embodiment 1

[0022] Immerse the nitrocellulose membrane with an average pore size of 0.45 μm and a thickness of 100 μm in PBS with a pH value of 8.0 and a concentration of 0.1 mol / L for 6 hours, take it out, and use high-purity N 2 Dry it, stick it on the O-shaped rubber ring, and compact it for 3 hours before use; use the phosphate buffer solution PBS with a pH value of 8.0 and a concentration of 0.1mol / L as a solvent to prepare uric acid oxidase activity of 2.5×10 4 The uric acid oxidase solution of U / L, preparation glutaraldehyde volume concentration is the glutaraldehyde solution of 5%, preparation ionic liquid 1-butyl-3-methylimidazole tetrafluoroborate volume concentration is 30% 1- Butyl-3-methylimidazolium tetrafluoroborate solution; respectively take 6 μL of urate oxidase solution, 6 μL of glutaraldehyde solution, and 3 μL of 1-butyl-3-methylimidazolium tetrafluoroborate solution for mixed cross-linking , drop-coated onto the nitrocellulose membrane that has been compacted on the ...

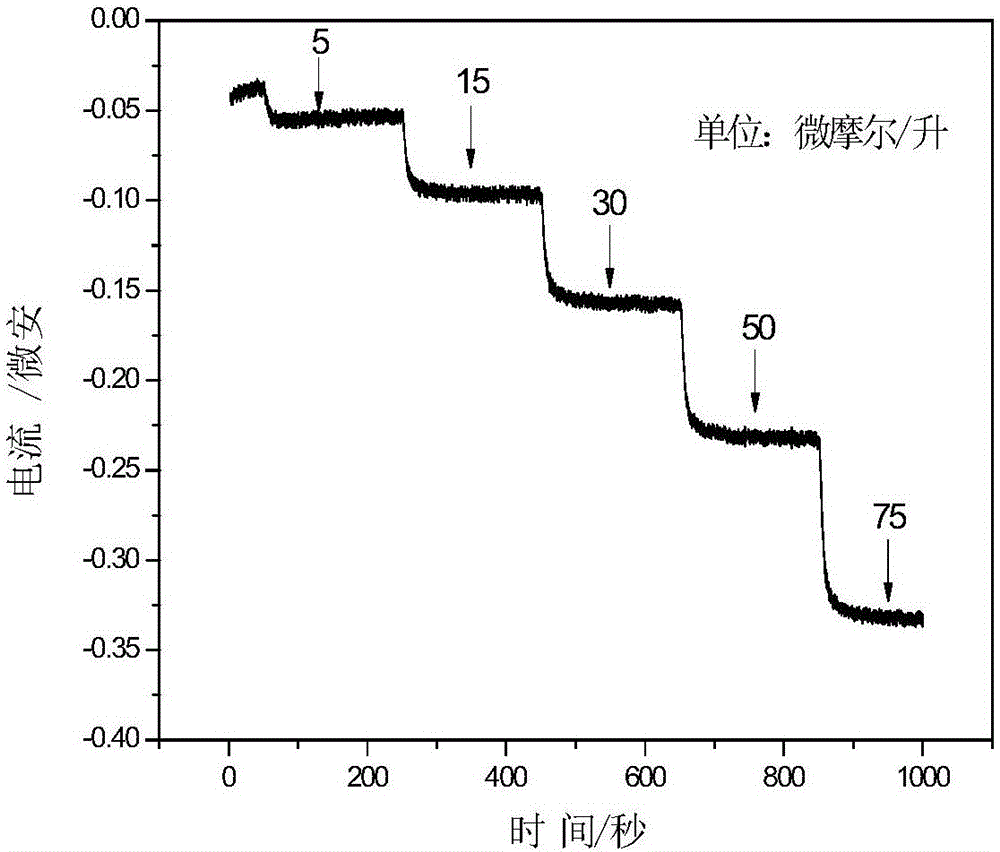

Embodiment 2

[0025] Immerse the nitrocellulose membrane with an average pore size of 0.50 μm and a thickness of 80 μm in a phosphate buffer solution with a pH value of 7.4 and a concentration of 0.1 mol / L for 7 hours, take it out, and use high-purity N 2 Blow dry, stick on the O-shaped rubber ring, compact for 4 hours and set aside; use phosphate buffer solution PBS with a pH value of 7.4 and a concentration of 0.1mol / L as a solvent to prepare uric acid oxidase activity of 3.0×10 4 The uric acid oxidase solution of U / L, preparation glutaraldehyde volume concentration is the glutaraldehyde solution of 3%, preparation ionic liquid 1-butyl-3-methylimidazole tetrafluoroborate volume concentration is 25% 1- Butyl-3-methylimidazolium tetrafluoroborate solution; respectively take 6 μL of urate oxidase solution, 6 μL of glutaraldehyde solution, and 3 μL of 1-butyl-3-methylimidazolium tetrafluoroborate solution for mixed cross-linking , drop-coated onto the nitrocellulose membrane that has been com...

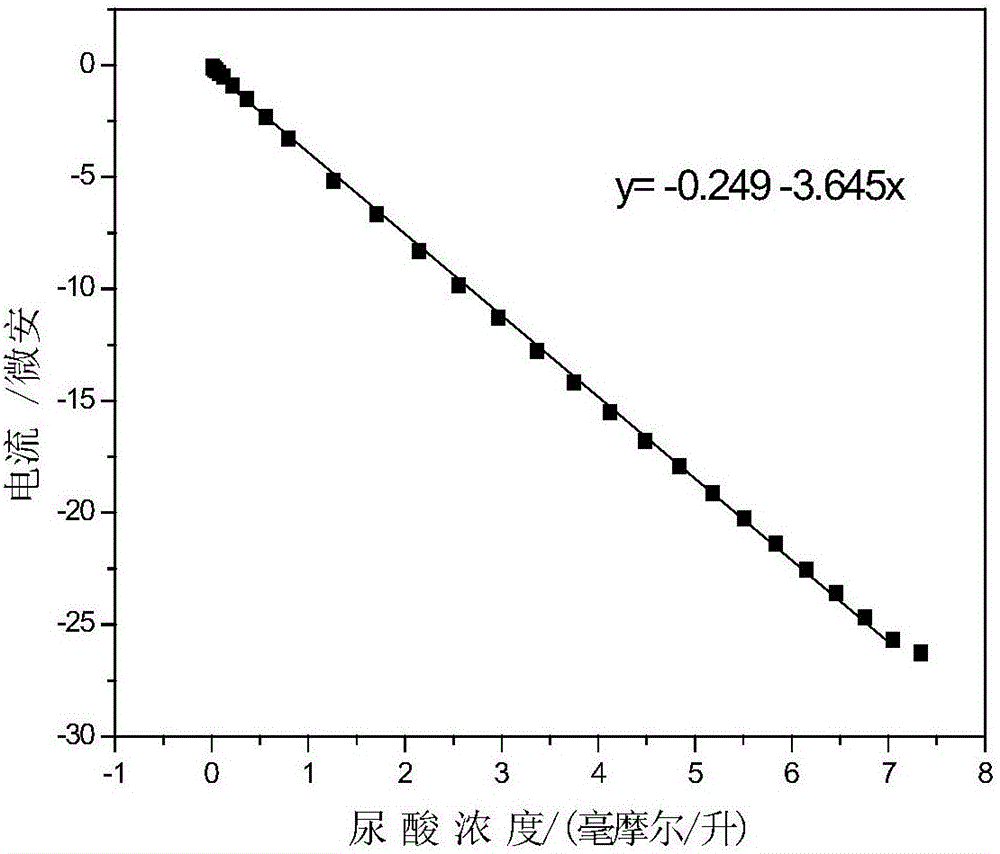

Embodiment 3

[0028] Immerse the nitrocellulose membrane with an average pore size of 0.8 μm and a thickness of 100 μm in a phosphate buffer solution with a pH value of 7.0 and a concentration of 0.1 mol / L for 6 hours, take it out, and use high-purity N 2 Dry it, stick it on the O-shaped rubber ring, and compact it for 3 hours before use; use the phosphate buffer solution PBS with a pH value of 7.0 and a concentration of 0.1mol / L as a solvent to prepare uric acid oxidase activity of 5.0×10 4 The uric acid oxidase solution of U / L, preparation glutaraldehyde volume concentration is the glutaraldehyde solution of 5%, preparation ionic liquid 1-butyl-3-methylimidazole tetrafluoroborate volume concentration is 20% 1- Butyl-3-methylimidazolium tetrafluoroborate solution; respectively take 6 μL of urate oxidase solution, 6 μL of glutaraldehyde solution, and 3 μL of 1-butyl-3-methylimidazolium tetrafluoroborate solution for mixed cross-linking , drop-coated onto the nitrocellulose membrane that has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com