Method for preparing star-like waterborne polyurethane associated type thickening agent

An associative thickener and water-based polyurethane technology, applied in the field of polyurethane materials, can solve the problems of difficult practical application, cumbersome synthesis of hydrophobic diol and star polyethylene glycol, etc., and achieve low construction viscosity, low cost, good The effect of the thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

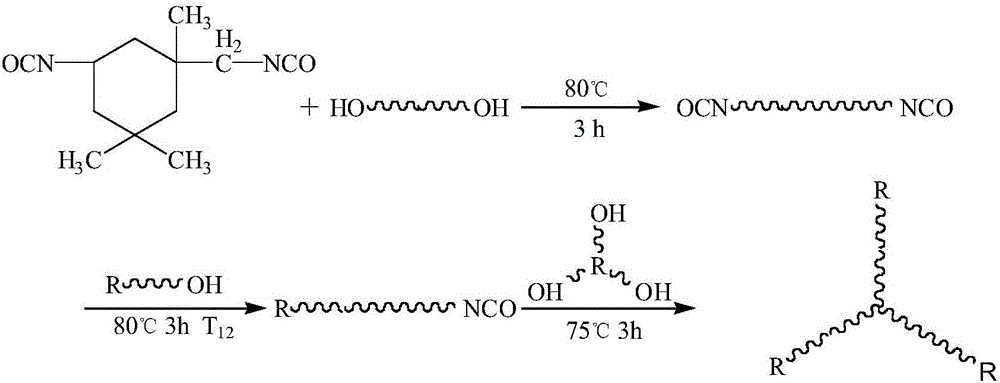

Problems solved by technology

Method used

Image

Examples

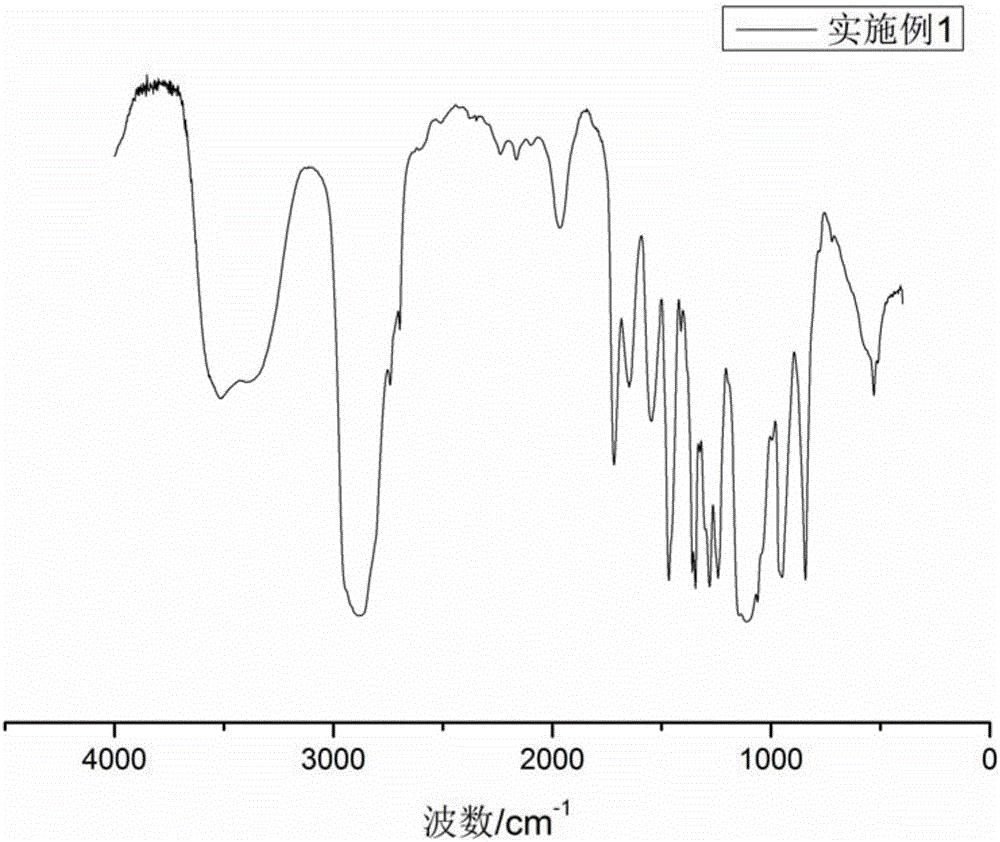

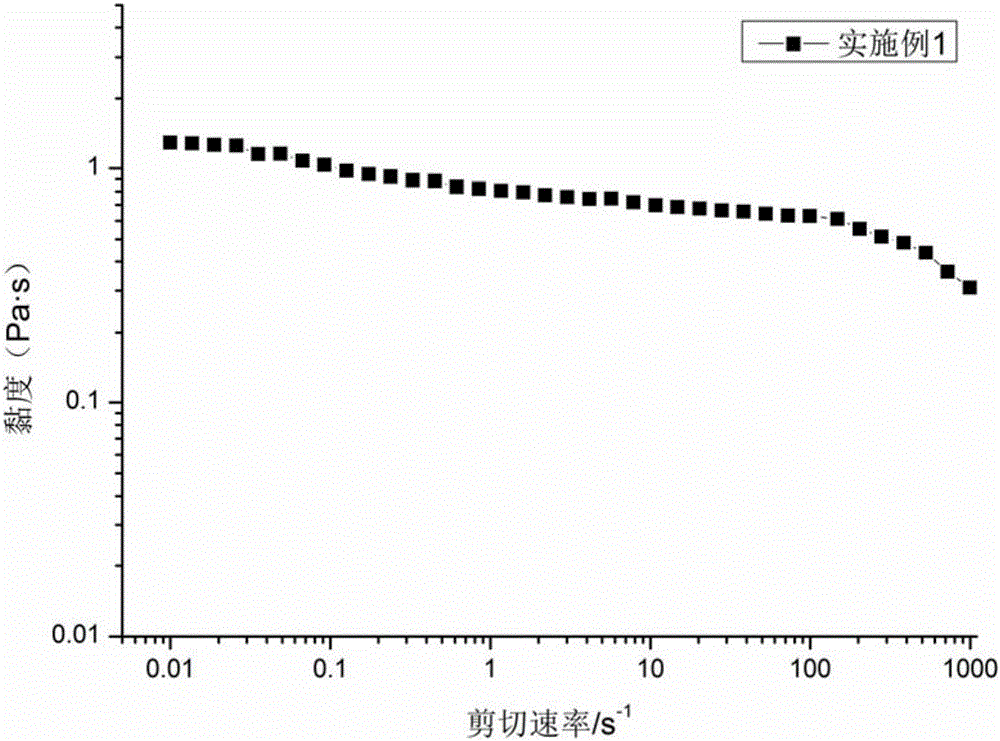

Embodiment 1

[0035] The preparation method of star-shaped waterborne polyurethane associative thickener in the present embodiment is as follows:

[0036] 1. Dehydration treatment

[0037] Add 40 g of polyethylene glycol with a molecular weight of 6000 g / mol into the reactor, raise the temperature to 110° C. for vacuum dehydration for 3 h;

[0038] 2. Prepolymerization

[0039] The polyethylene glycol after dehydration is cooled to 55 ℃, under the protection of nitrogen, the acetone solution of isophorone diisocyanate (IPDI) is added dropwise with stirring, the quality of isophorone diisocyanate is 2.96g, after dripping, in Insulate at 55°C for 10 minutes, then raise the temperature to 85°C for 3 hours to obtain a prepolymer.

[0040] 3. Half-capping reaction

[0041] After the prepolymerization reaction is completed, keep the temperature of the system at 85° C., add 1.61 g of cetyl alcohol and 0.06 g of dibutyltin dilaurate to the system for half-capping reaction, and react at 85° C. fo...

Embodiment 2

[0048] The preparation method of star-shaped waterborne polyurethane associative thickener in the present embodiment is as follows:

[0049] 1. Dehydration treatment

[0050] Add 40 g of polyethylene glycol with a molecular weight of 4000 g / mol into the reactor, and heat up to 110° C. for vacuum dehydration for 3 h;

[0051] 2. Prepolymerization

[0052] The polyethylene glycol after dehydration is cooled to 55 ℃, under the protection of nitrogen, the acetone solution of isophorone diisocyanate (IPDI) is added dropwise with stirring, the quality of isophorone diisocyanate is 4.44g, after dripping, in Insulate at 55°C for 10 minutes, then raise the temperature to 85°C for 3 hours to obtain a prepolymer.

[0053] 3. Half-capping reaction

[0054] After the prepolymerization reaction was completed, the temperature of the system was kept at 85° C., and 2.42 g of cetyl alcohol and 0.06 g of dibutyltin dilaurate were added to the system for half-capping reaction, and the reaction...

Embodiment 3

[0061] The preparation method of star-shaped waterborne polyurethane associative thickener in the present embodiment is as follows:

[0062] 1. Dehydration treatment

[0063] Add 40 g of polyethylene glycol with a molecular weight of 8000 g / mol into the reactor, raise the temperature to 110°C for vacuum dehydration for 3 h;

[0064] 2. Prepolymerization

[0065] The polyethylene glycol after dehydration is cooled to 55 ℃, under the protection of nitrogen, the acetone solution of isophorone diisocyanate (IPDI) is added dropwise with stirring, the quality of isophorone diisocyanate is 2.22g, after dropping, in Insulate at 55°C for 10 minutes, then raise the temperature to 85°C for 3 hours to obtain a prepolymer.

[0066] 3. Half-capping reaction

[0067] After the prepolymerization reaction was completed, the temperature of the system was kept at 85° C., 1.21 g of cetyl alcohol and 0.06 g of dibutyltin dilaurate were added to the system for half-capping reaction, and the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com