Preparation method and application of magnetic hollow graphene-based composite microsphere material

A graphene-based, composite microsphere technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of difficult recovery and separation, low adsorption performance, poor dispersion, etc., and achieve good adsorption effect and increase Saturated adsorption capacity, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

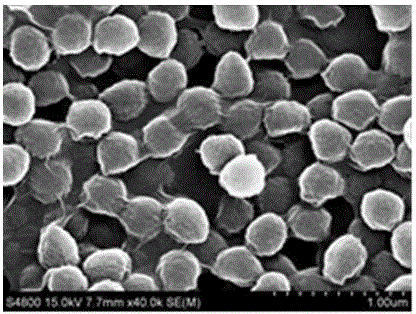

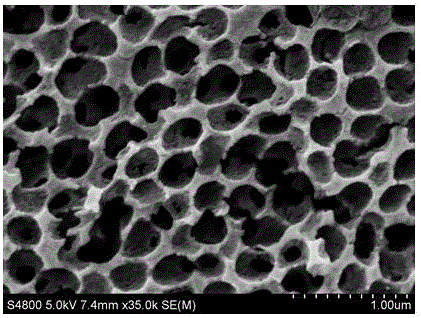

Image

Examples

Embodiment 1

[0043] The magnetic hollow graphene-based composite microsphere material was prepared in the following manner, and the microsphere material was used for adsorption experiments.

[0044] 1. Preparation of graphene oxide

[0045] Adopt improved Hummers method to prepare graphene oxide, its technological process is as follows: assemble reactor in ice-water bath, add 1g expanded graphite powder and 2.5g sodium nitrate in reaction bottle under stirring condition, then add 150ml mass percent to be 95 % concentrated sulfuric acid, reacted in an ice-water bath for 30min; then, added 15g of potassium permanganate, controlled the reaction temperature not to exceed 20°C, and continued the reaction for 12h; ℃, heat preservation for 48h, the color of the solution changed from black to brownish yellow, and the crude product of graphene oxide was obtained. 50ml of hydrogen peroxide with a mass fraction of 35% was added dropwise to the above crude product to reduce the remaining oxidant, and...

Embodiment 2

[0055] The magnetic hollow graphene-based composite microsphere material was prepared in the following manner, and the microsphere material was used for adsorption experiments.

[0056] 1. Preparation of graphene oxide

[0057] Adopt the improved Hummers method to prepare graphene oxide, and its technological process is as follows: assemble reactor in ice-water bath, add 1g expanded graphite powder and 2.5g sodium nitrate in reaction bottle under stirring condition, add 150ml mass percentage again and be 98 % concentrated sulfuric acid, reacted in an ice-water bath for 60 minutes; then, added 15g of potassium permanganate, controlled the reaction temperature not to exceed 20°C, and continued the reaction for 24 hours; ℃, heat preservation for 48h, the color of the solution changed from black to brownish yellow, and the crude product of graphene oxide was obtained. 50ml of hydrogen peroxide with a mass fraction of 35% was added dropwise to the above crude product to reduce the...

Embodiment 3

[0067] The magnetic hollow graphene-based composite microsphere material was prepared in the following manner, and the microsphere material was used for adsorption experiments.

[0068] 1. Preparation of graphene oxide

[0069] Adopt the improved Hummers method to prepare graphene oxide, and its technological process is as follows: assemble reactor in ice-water bath, add 1g expanded graphite powder and 2.5g sodium nitrate in reaction bottle under stirring condition, add 150ml mass percentage again and be 98 % concentrated sulfuric acid, reacted in an ice-water bath for 60 minutes; then, added 15g of potassium permanganate, controlled the reaction temperature not to exceed 20°C, and continued the reaction for 36 hours; ℃, heat preservation for 48h, the color of the solution changed from black to brownish yellow, and the crude product of graphene oxide was obtained. 50ml of hydrogen peroxide with a mass fraction of 35% was added dropwise to the above crude product to reduce the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com