Freeze-dried yoghurt powder and manufacturing method thereof

A production method and technology of yogurt powder, applied in milk preparations, dairy products, applications, etc., can solve problems such as inability to store for a long time, short shelf life of yogurt, bad flavor, etc., and achieve convenient consumption, smooth and uniform taste, and wide practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

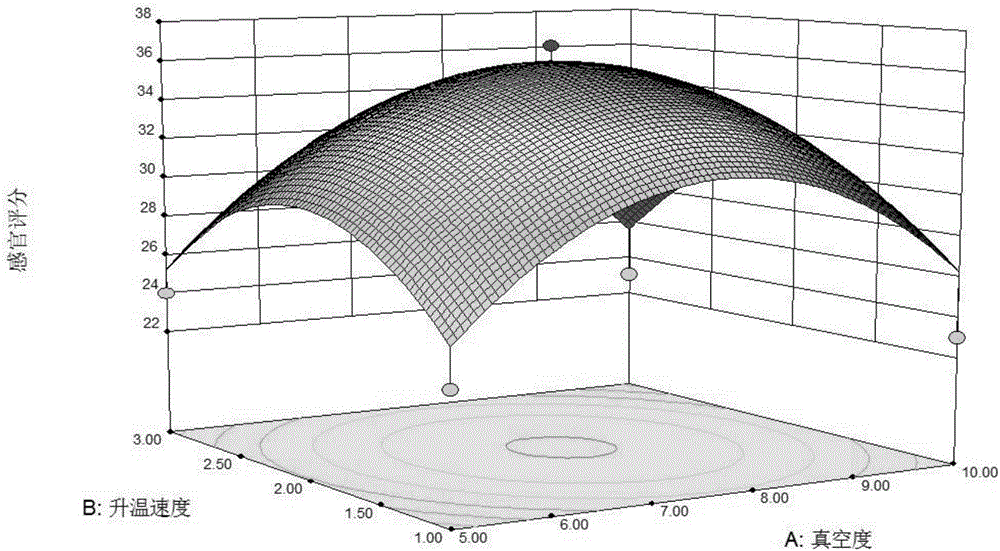

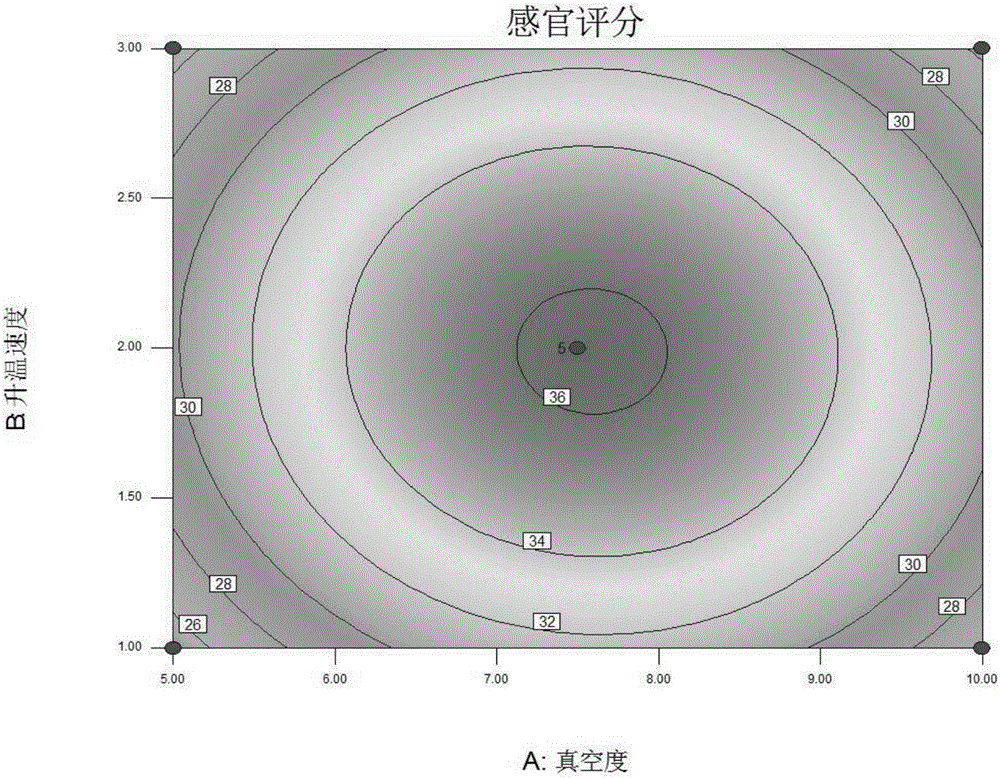

Image

Examples

Embodiment 1

[0037] Embodiment one: the preparation method of freeze-dried yoghurt powder

[0038]According to weight percentage, prepare fresh milk 40%-50%, whole milk powder 6%-9%, white granulated sugar 6%, galacto-oligosaccharide 1%, purified water 32%, mix evenly with agitator to prepare stock solution; Aseptically clean the colloid mill, suck the raw liquid into the colloid mill through the sanitary pump, pass through the colloid mill repeatedly for 3 times, preheat to 60°C, and transfer it to the storage tank through the homogenizer. The homogenization pressure of the first stage is 18MPa, and the Homogeneous pressure 8MPa; pump the emulsified stock solution into the sterilization tank, use steam heating method to sterilize at a constant temperature for 5 minutes at a pressure of 0.1MPa and a sterilization temperature of 90°C, cool to 43°C to maintain a constant temperature; pump the sterilized stock solution into stainless steel Fermentation tank, using lactic acid compound bacteri...

Embodiment 2

[0039] Embodiment two: the preparation method of freeze-dried yoghurt powder

[0040] According to weight percentage, configure fresh camel milk 50%, whole milk powder 9%, white granulated sugar 9%, galacto-oligosaccharide 1.5%, purified water 46%, mix uniformly with agitator to obtain stock solution; aseptic cleaning colloid mill , the raw liquid is sucked into the colloid mill through the sanitary pump, passed through the colloid mill repeatedly for 3 times, preheated to 65°C, passed through the homogenizer and transferred to the storage tank, the homogenization pressure of the first stage is 25MPa, and the homogenization pressure of the second stage is 12MPa; Pump the emulsified stock solution into a sterilization tank, use the steam heating method to sterilize at a constant temperature for 10 minutes at a pressure of 0.3MPa and a sterilization temperature of 95°C, and cool to 45°C to maintain a constant temperature; pump the sterilized stock solution into a stainless steel ...

Embodiment 3

[0041] Embodiment three: the preparation method of freeze-dried yoghurt powder

[0042] By weight percentage, configure fresh donkey milk 45%, whole milk powder 7%, white granulated sugar 8%, galacto-oligosaccharide 1.1%, purified water 35%, mix with agitator and make stock solution; Aseptic cleaning colloid mill , the raw liquid is sucked into the colloid mill through the sanitary pump, passed through the colloid mill repeatedly for 3 times, preheated to 62°C, passed through the homogenizer and transferred to the storage tank, the homogenization pressure of the first stage is 20MPa, and the homogenization pressure of the second stage is 9MPa; Pump the emulsified stock solution into the sterilization tank, use the steam heating method to sterilize at a constant temperature of 6 minutes at a pressure of 0.15MPa and a sterilization temperature of 92°C, and cool to 44°C to maintain a constant temperature; pump the sterilized stock solution into a stainless steel fermentation tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com