A mixed-pressure metal-based microwave printed board and its design method

A metal-based, printed board technology, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve the problem of difficult to meet the requirements of high power and large heat flow density, reduce the wiring space of the signal line of the radio frequency layer, and affect the radio frequency ground. Plane integrity and other issues, to optimize the heat dissipation effect of the circuit, avoid the deterioration of transmission performance and processing difficulties, and facilitate the effect of metal-based structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

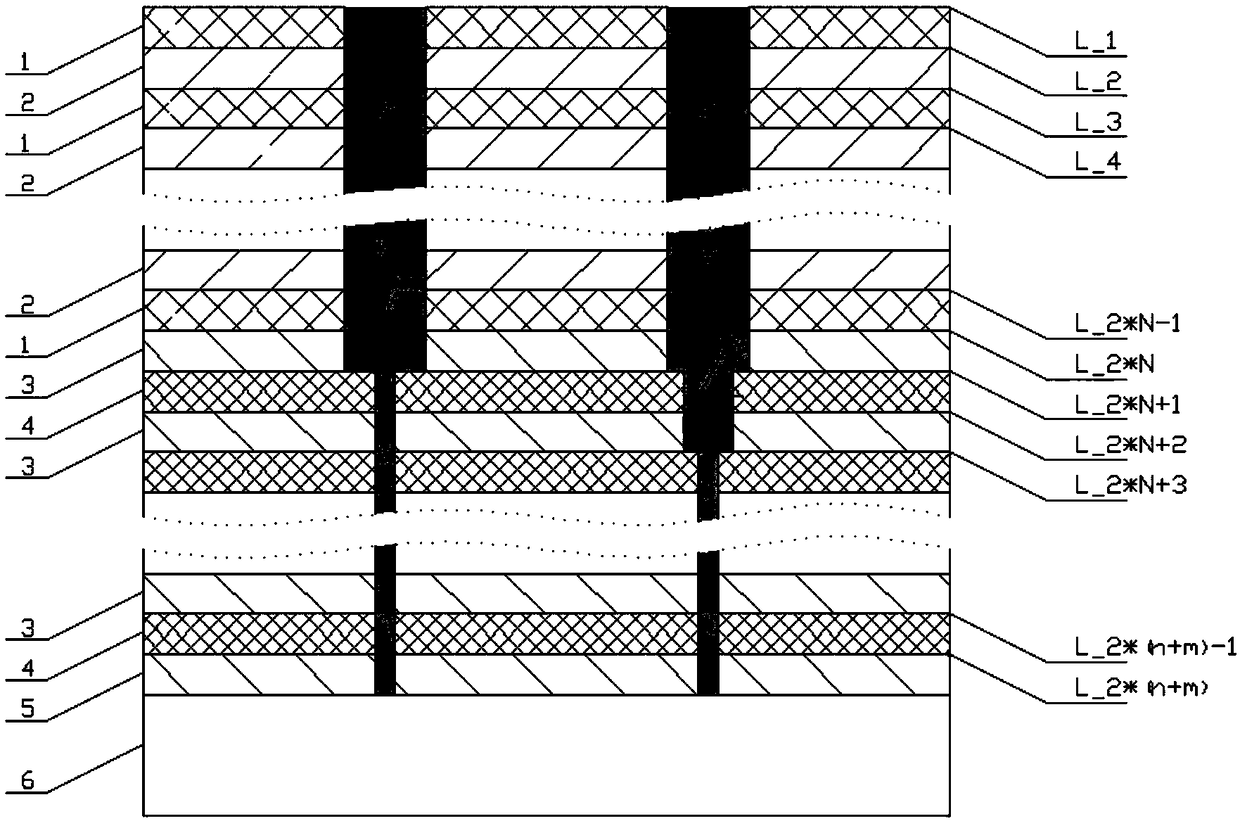

[0039] The metal-based printed board is processed by the PCB manufacturing process from a high-frequency laminated structure (including a high-frequency core board and a high-frequency adhesive sheet), a low-frequency laminated structure (including a low-frequency core board and a low-frequency adhesive sheet), and a metal base.

[0040] The low-frequency core board in the low-frequency laminated structure is used for low-frequency wiring, and the high-frequency core board in the high-frequency laminated structure is used for high-frequency wiring. The interlayer interconnection of radio frequency signals adopts a blind hole structure, which only penetrates the high-frequency stacked structure and avoids passing through the low-frequency structure. The low-frequency laminated structure adopts a blind hole structure, which mainly penetrates the low-frequency core board and the low-frequency adhesive sheet, and avoids passing through the high-frequency laminated structure as much...

Embodiment 2

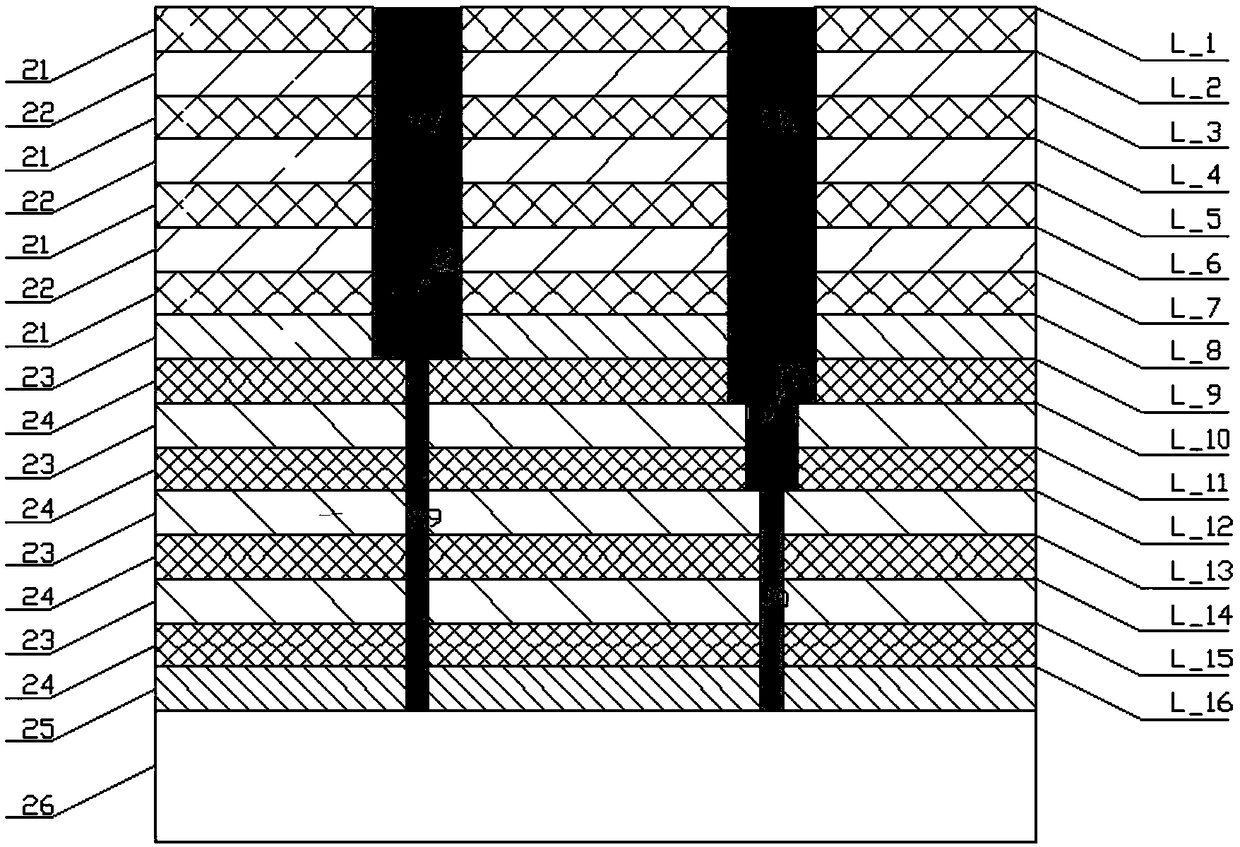

[0049] A 16-layer board is designed, see the structure figure 2 . figure 2 Among them, 21 is a low-frequency core board, 22 is a low-frequency adhesive sheet, 23 is a high-frequency adhesive sheet, 24 is a high-frequency core board, 25 is an adhesive sheet, 26 is a metal base, 27 and 28 are sidewall metallized blind Grooves, 29 and 30 are metallized vias, and 31 and 32 are components. The number of wiring layers of the printed board is 16. L_1, L_2, L_3, ..., L_16 in sequence.

[0050] The dielectric constant of the selected low-frequency core board and low-frequency bonding sheet is 4.5, the dielectric constant of the high-frequency core board and high-frequency bonding sheet is 2.9, the metal base material is copper, and the bonding between the high-frequency material and the copper base is The sheet is conductive glue. The thickness of the high and low frequency boards after lamination is 3.0mm (excluding the metal base), and the thickness of the finished board after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com