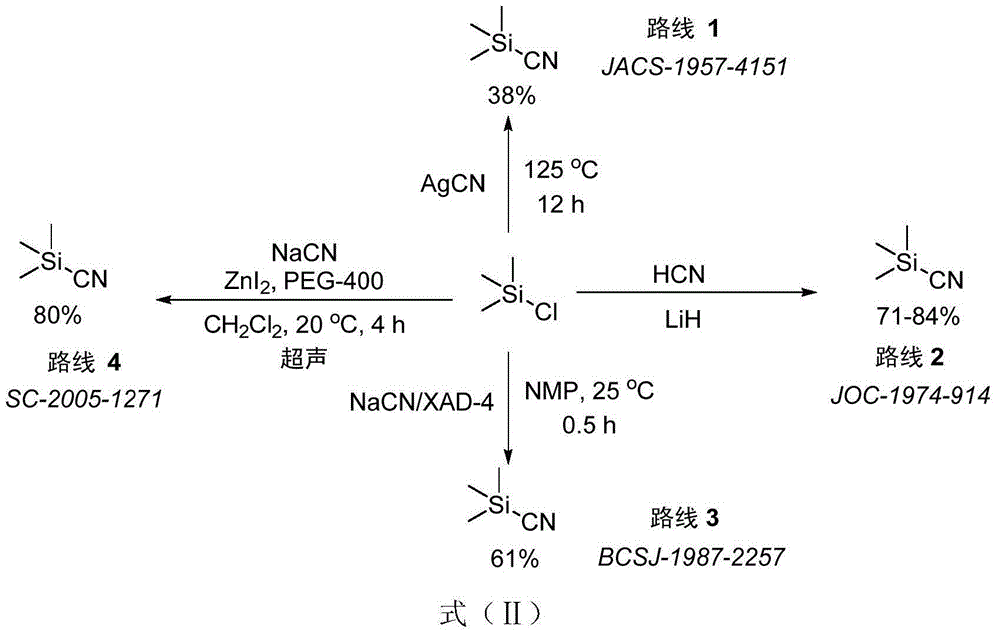

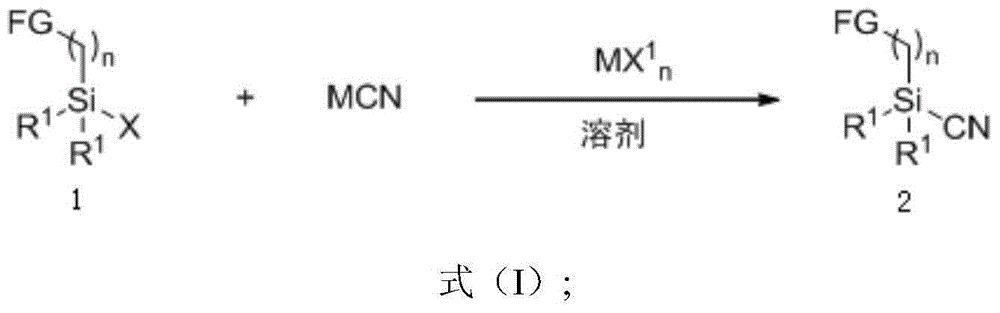

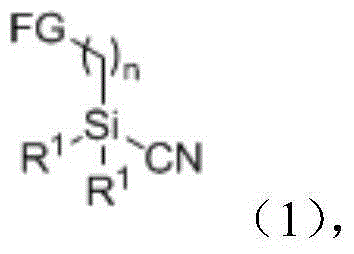

Functionalized cyanosilane, synthesis method and applications thereof

A technology of functional grouping and synthesis method, which is applied in the field of organic compound process application, can solve the problems of increased risk of reaction operation, low atom economy, no literature reports, etc., achieves convenient post-treatment process, wide source of raw materials, and improves synthesis efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 42

[0058] Example 42: The hydrosilylation reaction of the functionalized cyanosilane 2a synthesized in Example 4

[0059]

[0060] In a dry 25 mL Schlenk tube, add (R,R)-Salen / Al (3.0 mg, 0.005 mmol), Ph 3 PO (13.9mg, 0.05mmol), 3a (70mg, 0.5mmol) and anhydrous dichloromethane (1.0mL), the resulting mixed solution was stirred at -30°C for 0.5h, then 2a (125μL, 1.0mmol) was added, and the reaction The process was monitored by thin-layer chromatography. After the raw material 3a was consumed, 4a as shown in formula (V) could be obtained through direct column chromatography with a yield of 93%.

[0061] 2H),5.83(s,1H),2.86(s,2H),0.56(s,6H); 13 C NMR (100MHz, CDCl 3 ): δ133.9, 130.2, 128.5, 120.5, 118.4, 64.8, 37.6, -0.58;

Embodiment 43

[0062] Example 43: The hydrosilylation reaction of the functionalized cyanosilane 2a synthesized in Example 4

[0063]

[0064] In a dry 25 mL Schlenk tube, add (R,R)-Salen / Al (3.0 mg, 0.005 mmol), Ph 3 PO (41.7mg, 0.15mmol), 6a (77mg, 0.5mmol) and anhydrous dichloromethane (1.0mL), the resulting mixed solution was stirred at 25°C for 0.5h and then 2a (125μL, 1.0mmol) was added, the reaction process Monitored by thin-layer chromatography, after the raw material 6a was consumed, 7a as shown in formula (VI) could be obtained through direct column chromatography with a yield of 95%.

[0065] 2H), 2.86(s, 2H), 1.87(s, 3H), 0.59(s, 6H); 13 C NMR (100MHz, CDCl 3 ): δ134.9, 128.3, 125.5, 119.5, 118.4, 65.6, 36.7, 30.9, -0.57.

Embodiment 4

[0066] Example 44: The hydrosilylation reaction of the functionalized cyanosilane 2a synthesized in Example 4

[0067]

[0068] In a dry 25 mL Schlenk tube, add (R,R)-Salen / Al (3.0 mg, 0.005 mmol), Ph 3 PO (41.7mg, 0.15mmol), 9a (74mg, 0.5mmol) and anhydrous dichloromethane (1.0mL), the resulting mixed solution was stirred at 25°C for 0.5h and then 2a (125μL, 1.0mmol) was added, the reaction process Monitored by thin layer chromatography, after the raw material 9a was consumed, 10a as shown in formula (VII) could be obtained through direct column chromatography with a yield of 89%.

[0069] 2H),2.16(s,3H),1.78(s,3H),0.33(s,6H); 13 C NMR (100MHz, CDCl 3 ): δ142.9, 125.9, 128.5, 128.1, 120.4, 67.9, 42.5, 35.7, 27.8, 25.9, -0.57.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com