A kind of multilayer structure aluminum oxide composite ceramics and preparation method thereof

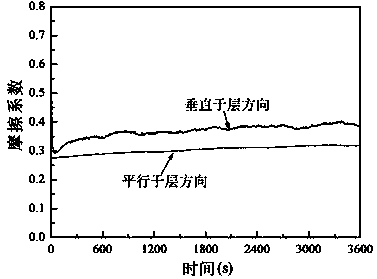

A composite ceramic, multi-layer structure technology, applied in chemical instruments and methods, ceramic layered products, lamination and other directions, can solve the problems of poor reliability and lubricity, hinder practical application, low stability, etc., achieve high reliability, Excellent thermal shock resistance, low friction and wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

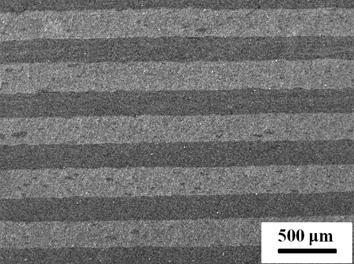

[0037] Alumina particles can be obtained by ball milling 90 g of alumina powder with a particle size range of 100-200 mesh, 5 g of tetragonal polycrystalline zirconia and 5 g of sintering aids (4 g of titanium dioxide and 1 g of copper oxide) in an alcohol medium for 24 hours. Ultrafine alumina composite powder with a diameter of 50 nm to 200 nm; obtained by wet ball milling the above 70.0 g ultrafine alumina composite powder, 29.5 g deionized water and 0.5 g binder (polyvinyl alcohol) for 10 hours Alumina slurry: the mixed alumina slurry was tape-cast, and dried at room temperature to obtain an alumina spacer layer with a thickness of 1.2 mm.

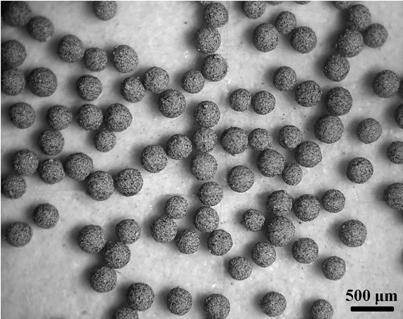

[0038]Put 7.0 g of colloidal graphite, 2.8 g of deionized water, and 0.2 g of polyvinyl alcohol into a ball mill jar, and carry out wet ball milling for 10 hours to obtain a slurry composed of colloidal graphite and binder; the above composite slurry was spray-dried Granulation to prepare large-particle spherical graphite lubricant pow...

Embodiment 2

[0041] 94.5 g of alumina, 4 g of titanium dioxide, 1 g of copper oxide and 0.05 g of graphene with a particle size range of 100-200 mesh were ball-milled in an alcohol medium for 25 hours to obtain ultrafine aluminum oxide particles with a particle size of 50 nm to 200 nm. Alumina composite powder; the above 70.0 g ultrafine alumina composite powder, 29.5 g deionized water and 0.5 g polyvinyl alcohol were wet ball milled for 10 hours to obtain alumina slurry; the mixed alumina slurry was flown After stretching and drying at room temperature, an aluminum oxide spacer layer with a thickness of 0.35 mm was obtained.

[0042] 7.0 g of colloidal graphite, 2.8 g of deionized water and 0.2 g of polyvinyl alcohol were packed into a ball mill jar, and wet ball milled for 10 hours to obtain a slurry composed of colloidal graphite and binder; the above-mentioned composite slurry was produced by spray drying granules to prepare large-particle spherical graphite lubricant powder; heat-trea...

Embodiment 3

[0045] 95 g of alumina with a particle size range of 100-200 mesh, 4 g of titanium dioxide and 1 g of copper oxide are ball milled in an alcohol medium for 24 hours to obtain an ultrafine alumina composite powder with a particle size of 50 nm to 200 nm ; The above 70.0 g ultrafine alumina composite powder, 29.5 g deionized water and 0.5 g polyvinyl alcohol were wet ball milled for 12 hours to obtain alumina slurry; the mixed alumina slurry was cast and dried at room temperature Finally, an aluminum oxide spacer layer with a thickness of 0.45 mm was obtained.

[0046] 7.0 g of colloidal graphite, 2.8 g of deionized water and 0.2 g of polyvinyl alcohol were packed into a ball mill jar, and after 10 hours of wet ball milling, a slurry composed of colloidal graphite and binder was obtained; the above-mentioned composite slurry was produced by spray drying granules to prepare large-particle spherical graphite lubricant powder; the large-particle spherical graphite lubricant powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com