Flocculating agent for treating coking wastewater, and preparation method and application thereof

A technology for coking wastewater and flocculants, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve threats to human health, increase in aluminum content, and effluent chromaticity that does not meet discharge requirements and other problems, to achieve the effect of large flocs, high activity and non-corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

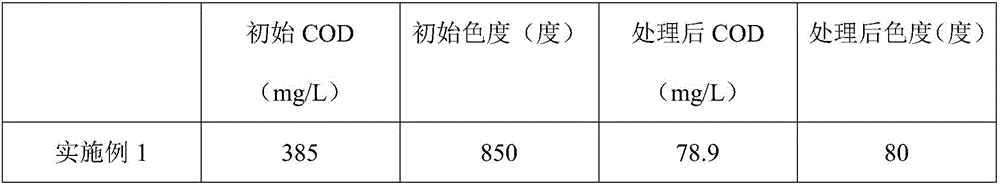

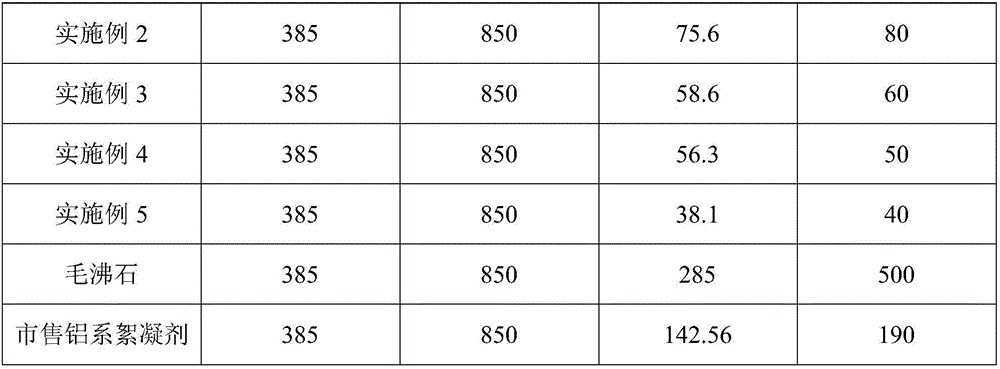

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a flocculant for treating coking wastewater is composed of the following raw materials in parts by weight: 30 parts of erionite, 8 parts of rosin glyceride, 1 part of aluminum stearate, and 5 parts of acrylic acid emulsion.

[0018] Aluminum stearate is mixed with an aqueous solution of sodium hydroxide whose quality is 8 times that of the aluminum stearate solution, and the mass content of sodium hydroxide in the aqueous solution of sodium hydroxide is 5%; 150-mesh sieve, add aluminum stearate solution, seal and soak at 62°C for 2h, then raise the temperature to 95°C and heat and stir at this temperature for 40min to prepare the pretreatment material. Mix the acrylic emulsion with the pretreatment material, seal and stir for 50 minutes under an ozone atmosphere at a temperature of 68°C, then perform ultrasonic treatment for 45 minutes with an ultrasonic power of 800W, then put it into a reaction kettle and raise the temperatur...

Embodiment 2

[0020] In the embodiment of the present invention, a flocculant for treating coking wastewater is composed of the following raw materials in parts by weight: 38 parts of erionite, 16 parts of rosin glyceride, 8 parts of aluminum stearate, and 13 parts of acrylic acid emulsion.

[0021] Aluminum stearate is mixed with an aqueous solution of sodium hydroxide whose quality is 8 times that of the aluminum stearate solution, and the mass content of sodium hydroxide in the aqueous solution of sodium hydroxide is 5%; 150-mesh sieve, add aluminum stearate solution, seal and soak at 62°C for 2h, then raise the temperature to 95°C and heat and stir at this temperature for 40min to prepare the pretreatment material. Mix the acrylic emulsion with the pretreatment material, seal and stir for 60 minutes at 68°C under an ozone atmosphere, then perform ultrasonic treatment for 45 minutes with an ultrasonic power of 800W, then put it into a reaction kettle and raise the temperature to 350°C und...

Embodiment 3

[0023] In the embodiment of the present invention, a flocculant for treating coking wastewater is composed of the following raw materials in parts by weight: 32 parts of erionite, 10 parts of rosin glyceride, 3 parts of aluminum stearate, and 7 parts of acrylic acid emulsion.

[0024] Aluminum stearate is mixed with an aqueous solution of sodium hydroxide whose quality is 8 times that of the aluminum stearate solution, and the mass content of sodium hydroxide in the aqueous solution of sodium hydroxide is 5%; 150-mesh sieve, add aluminum stearate solution, seal and soak at 62°C for 2h, then raise the temperature to 95°C and heat and stir at this temperature for 40min to prepare the pretreatment material. Mix the acrylic emulsion with the pretreatment material, seal and stir for 55 minutes at 68°C under an ozone atmosphere, and then perform ultrasonic treatment for 45 minutes with an ultrasonic power of 800W, then put it into a reaction kettle and raise the temperature to 350°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com