Electrode for synchronously removing nitrate and tetrachloromethane from water and preparation method and use method thereof

A carbon tetrachloride, nitrate technology, applied in chemical instruments and methods, water/sewage treatment equipment, water pollutants, etc., can solve the problems of high applied voltage, not considering the interaction between nitrate and carbon tetrachloride, etc. , to achieve good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

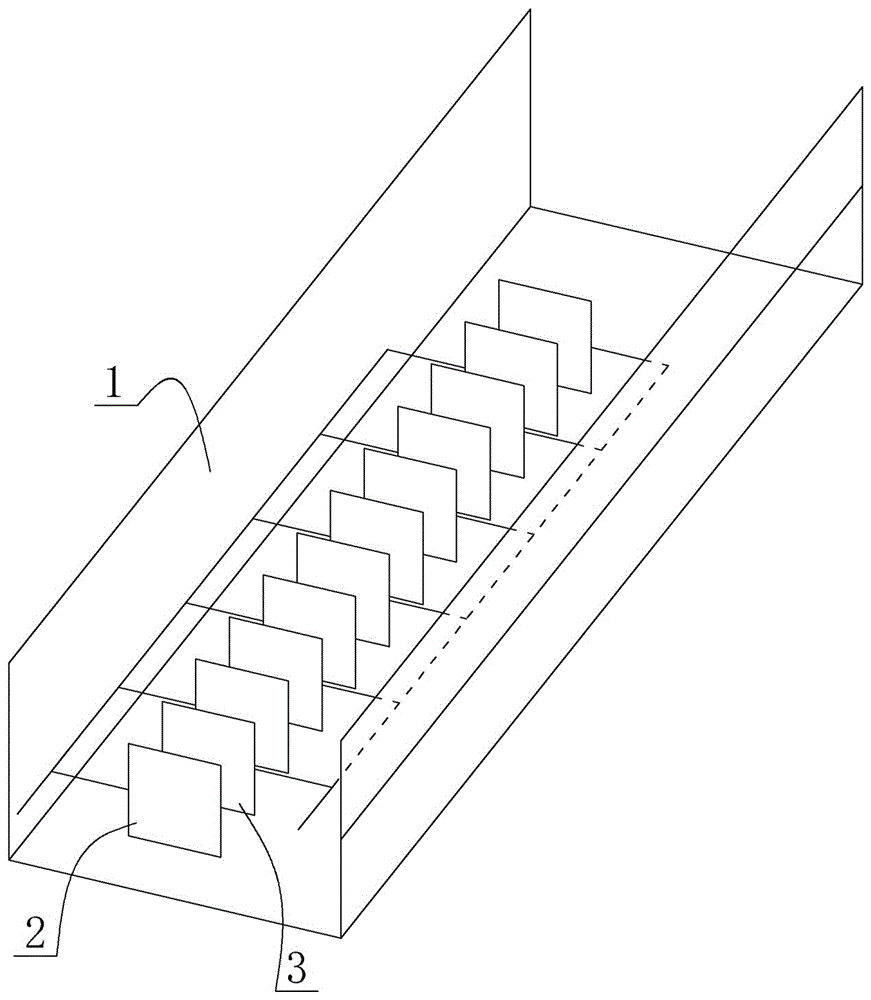

Image

Examples

Embodiment 1

[0033] The cast iron and aluminum ingots were put into the melting furnace according to the mass ratio of total aluminum to total iron of 80%:20%, and heated and melted at 1500°C. After being discharged and cooled, the obtained alloy block is wire-cut to obtain an aluminum-iron alloy electrode material with a length of 1 cm×1 cm×1 mm. Wires are welded on the prepared electrodes, and the electrode solder joints and other parts that do not need to be exposed to conduction are sealed with epoxy resin. The Al-Fe alloy electrode is put into the cathode chamber, and the saturated calomel reference electrode is connected with a salt bridge.

[0034] At room temperature, measure 15 ml of an aqueous solution containing nitrate concentration of 56 mg / L, carbon tetrachloride concentration of 1200 μg / L, and supporting electrolyte of 0.01 mol. / L KCl into the cathode chamber without adjusting the pH of the solution. The applied voltage is -1.4 V. After each water sample passed through a 0.22...

Embodiment 2

[0036] The cast iron and aluminum ingots were put into the melting furnace according to the mass ratio of total aluminum to total iron of 90%:10%, and heated and melted at 1300°C. After being discharged and cooled, the obtained alloy block is wire-cut to obtain an aluminum-iron alloy electrode material with a length of 1 cm×1 cm×1 mm. Wires are welded on the prepared electrodes, and the electrode solder joints and other parts that do not need to be exposed to conduction are sealed with epoxy resin. The Al-Fe alloy electrode is put into the cathode chamber, and the saturated calomel reference electrode is connected with a salt bridge.

[0037] At room temperature, measure 15 ml of an aqueous solution with a nitrate concentration of 14 mg / L, a carbon tetrachloride concentration of 1200 μg / L, and a supporting electrolyte of 0.01 mol. / L KCl into the cathode chamber without adjusting the pH of the solution. The applied voltage is -1.2 V. After each water sample passed through a 0.22...

Embodiment 3

[0039] The cast iron and aluminum ingot are put into the melting furnace according to the mass ratio of total aluminum to total iron of 90%:10%, and heated and melted at 1000°C. After being discharged and cooled, the obtained alloy block is wire-cut to obtain an aluminum-iron alloy electrode material with a length of 1 cm×1 cm×1 mm. Wires are welded on the prepared electrodes, and the electrode solder joints and other parts that do not need to be exposed to conduction are sealed with epoxy resin. The Al-Fe alloy electrode is put into the cathode chamber, and the saturated calomel reference electrode is connected with a salt bridge.

[0040] At room temperature, measure 15 ml of an aqueous solution with a nitrate concentration of 28 mg / L, a carbon tetrachloride concentration of 600 μg / L, and a supporting electrolyte of 0.01 mol. / L KCl into the cathode chamber without adjusting the pH of the solution. The applied voltage is -1.2 V. After each water sample passed through a 0.22 µm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com