Resistance spot welding technology for improving quality of welding spots of dual-phase steel

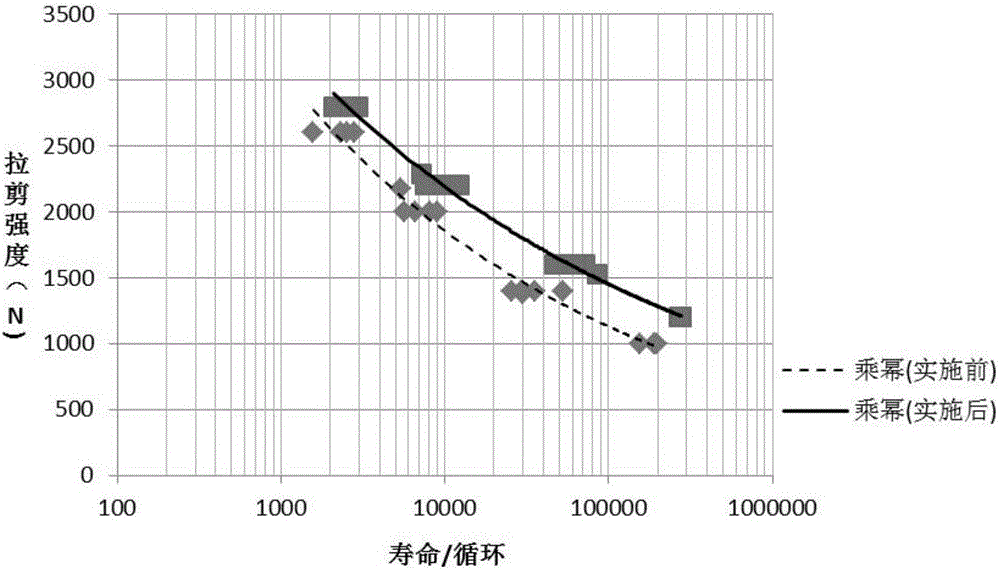

A technology of resistance spot welding and dual-phase steel, applied in resistance welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems affecting the quality of dual-phase steel solder joints, reducing the bearing capacity of joints, and hidden dangers to automobile safety , to achieve high fatigue strength, improve welding strength and toughness, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

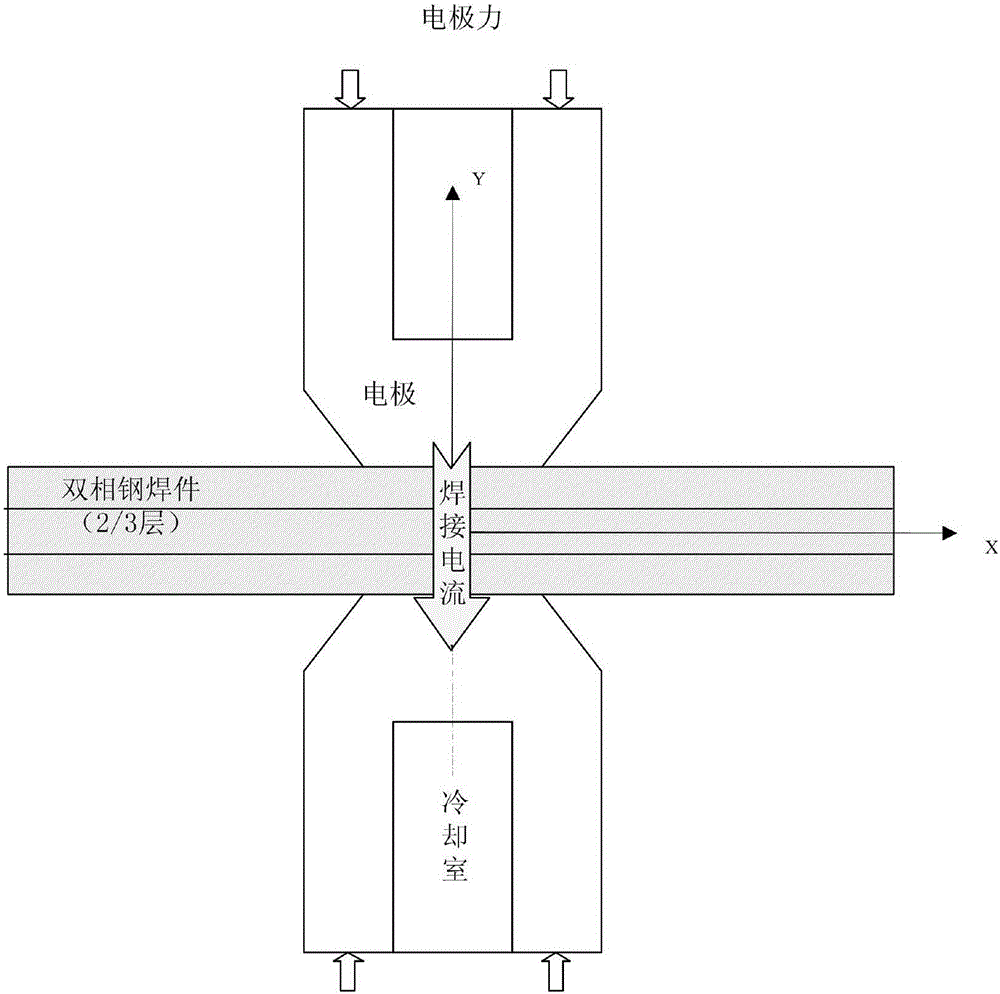

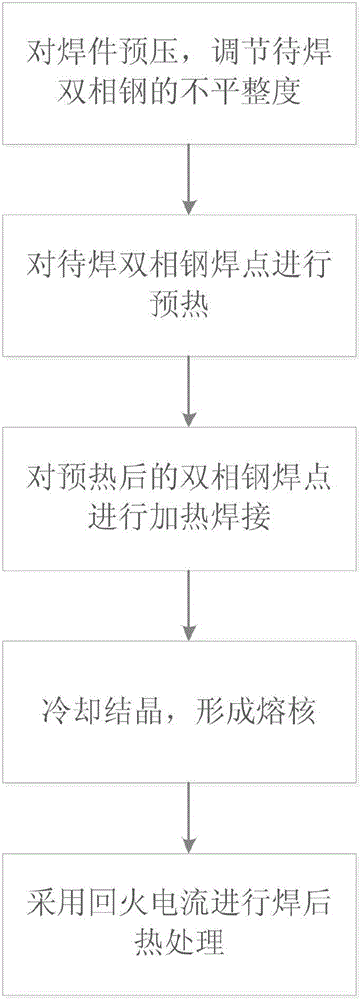

[0020] First of all, in order to avoid the adverse effects of other components on the surface on the welding quality, before welding the dual-phase steel to be welded, the surface is cleaned with acetone to ensure the cleanliness of the part to be welded. A schematic diagram of resistance spot welding and a process flow chart for improving the quality of dual-phase steel solder joints provided by the present invention are specifically as follows figure 1 , 2 As shown, it includes the following steps:

[0021] (a) Initially pressurize the dual-phase steel to be welded, and the pressurization time is 100-500ms, so that the two dual-phase steel plates are closely bonded, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com