Continuous casting tundish

A continuous casting tundish and tundish technology, which is applied in casting equipment, casting molten material containers, manufacturing tools, etc., can solve the inconsistency of heat loss at multiple water outlets, filter and remove impurities from molten steel that has not been injected, and reduce the use of tundishes Life and other issues, to improve product quality, avoid loss of raw materials, prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

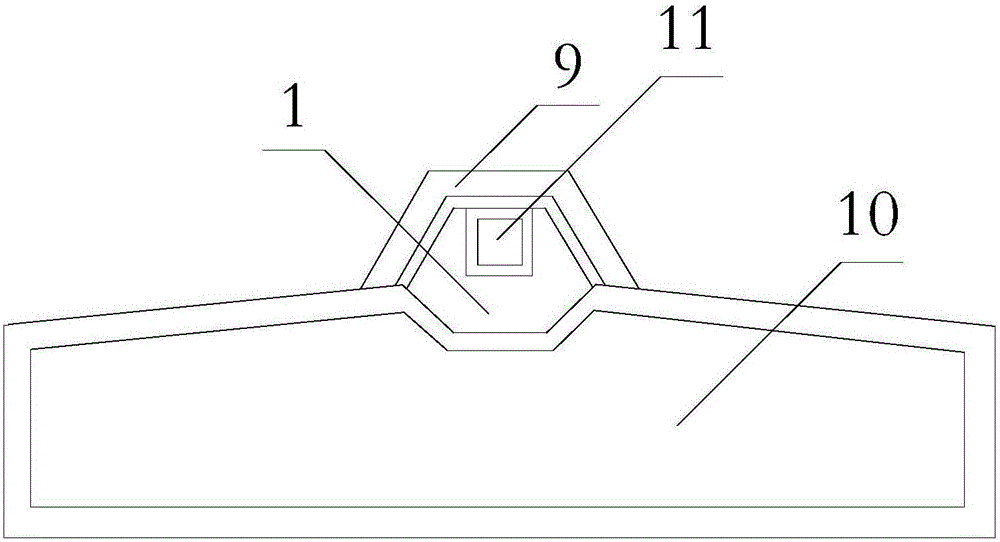

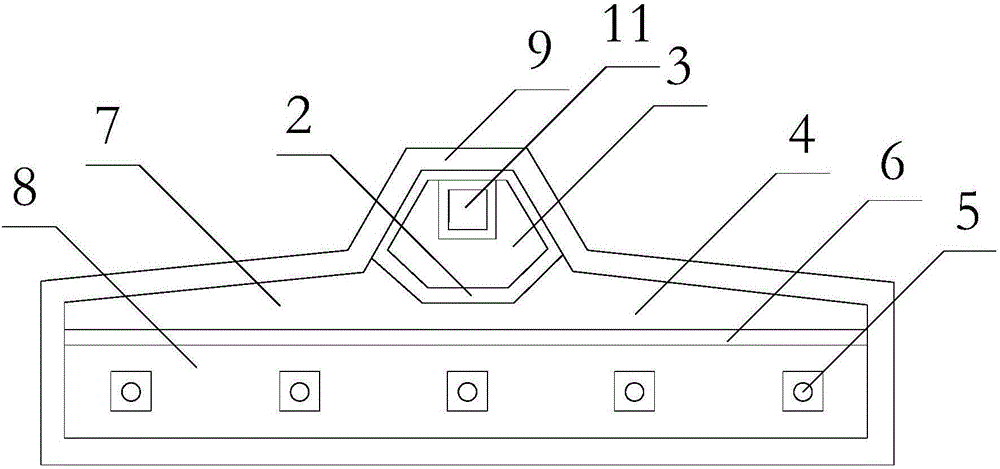

[0034] like Figures 1 to 4 As shown, a continuous casting tundish, the tundish is hollow and three-dimensional, the upper end of the tundish is provided with a feed port 1, and a filter wall 2 is vertically provided in the tundish, and the filter wall 2 Divide the internal space of the tundish into a blanking area 3 and a splitting area 4, and the feed inlet 1 is located directly above the blanking area 3, and the bottom surface of the tundish is located in the splitting area 4 There are multiple diversion ports 5 .

[0035] In the tundish, a flow equalizing plate 6 is vertically arranged in the flow splitting area 4, and the flow equalizing plate 6 divides the flow splitting area 4 into a flow storage area 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com