Method for correcting overall distorsion of structural plate after laser forming

A laser forming and structural plate technology, applied in the field of plate processing, can solve the problems of long aging forming cycle, low forming efficiency, plate distortion and other problems, and achieve the effect of improving effectiveness and yield, reasonable strategy and clear organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

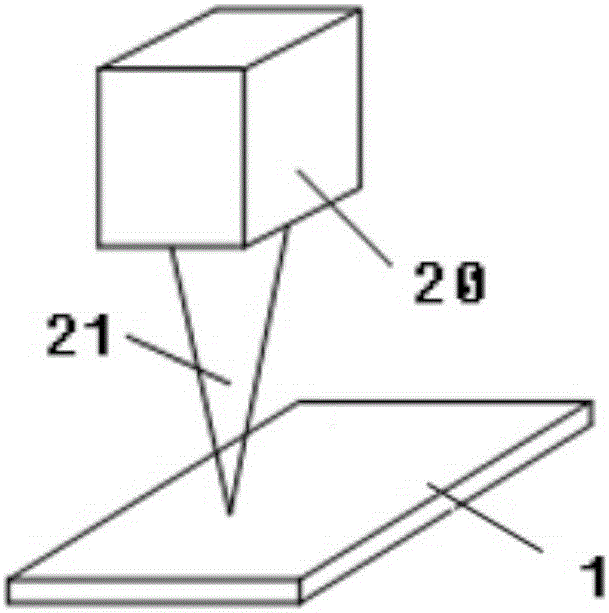

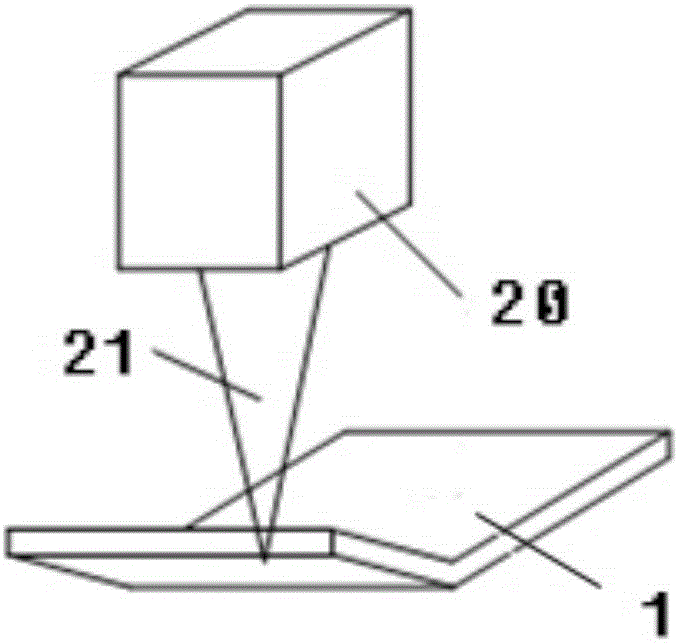

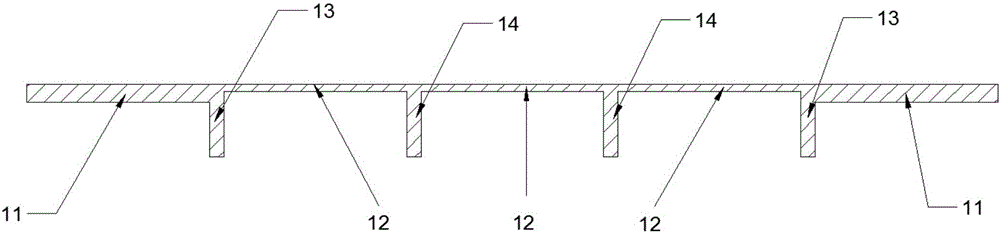

[0029] As described above, the method for correcting the overall distortion of the lightweight structural panel is different from this embodiment in that: figure 2 As shown, the method for correcting the overall distortion of the lightweight structural plate after laser forming, the specific implementation steps are as follows:

[0030] Step 1: Fix the overall twisted lightweight structural plate on the workbench with a clamp, using the same fixing method as before the laser forming of the lightweight structural plate;

[0031] Step 2: Use the supporting device to support the two ends of the twisted end of the overall twisted and deformed lightweight structural panel; and initially correct the panel;

[0032] Step 3: Measure the deformation of different parts of the scanning line of the light-weight structural board after correction;

[0033] Step 4: Classify the deformation of the lightweight structural plate according to the measurement results: (1) The bending deformation of the r...

Embodiment 2

[0038] Like the method for correcting the overall distortion of the lightweight structural panel described above, this embodiment is different from that in step 4, measuring the deformation of different parts of the corrected scanning line of the lightweight structural panel, and the measurement method can be three-dimensional Scanner, laser displacement meter and other equipment.

Embodiment 3

[0040] As the method for correcting the overall distortion of the lightweight structure board as described above, the difference between this embodiment and the lightweight structure is that the overall size of the lightweight structure is 696mm×400mm. The forming experiment is carried out. The surface of the board is coated with graphite. The parameters are: laser power 1100W, scanning speed 20mm / s, spot diameter 12mm, in the grid unit area 90mm, 126mm, and 162mm away from the free end of the sheet, the scanning strategy of constant speed, constant power and constant spot size is used in each scanning position. After scanning for five times, the overall distortion of the lightweight structure board was generated after scanning. After the overall distortion of the board was corrected by the supporting device, the deformation of the board was measured. The measurement device was carried out by the Canadian CREAFORM handheld 3D scanner. As a result, the bending deformation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com