Conductive slip ring integrating circular inductive synchronizer and preparation method thereof

A technology of circular induction synchronizer and conductive slip ring, which can be applied to instruments, electric devices, electromagnetic means, etc., can solve the problems of twisted wires and increase of system volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

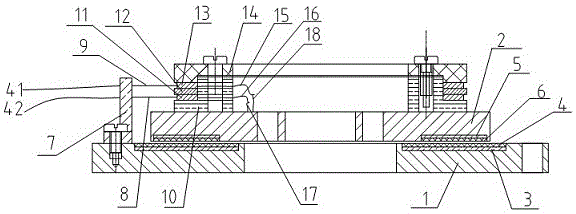

[0034] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0035]A circular induction synchronizer integrated with a conductive slip ring, including a stator base plate 1 installed on a fixed body and a rotor base plate 2 installed on a rotating shaft. Both the stator base plate 1 and the rotor base plate 2 are made of metal materials. A stator insulating layer 3 is fixed on the upper surface, a ring-shaped stator metal winding 4 is fixed on the stator insulating layer 3, a rotor insulating layer 5 corresponding to the position of the stator insulating layer is fixed on the lower surface of the rotor substrate 2, and a rotor insulating layer 5 is fixed on the rotor insulating layer. The ring-shaped rotor metal winding 6 is fixed on the 5, the stator metal winding 4 is placed opposite to the rotor metal winding 6, the stator metal winding 4 and the rotor metal winding 6 are both pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com