Off-location ultrasonic cleaning method of heat exchanger of aircraft air conditioning system

A technology of heat exchanger and air conditioning system, applied in the field of civil aviation, can solve the problems of difficult mechanical work, poor disintegration effect of scale and transfer to the heat exchanger, etc. Disintegration-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

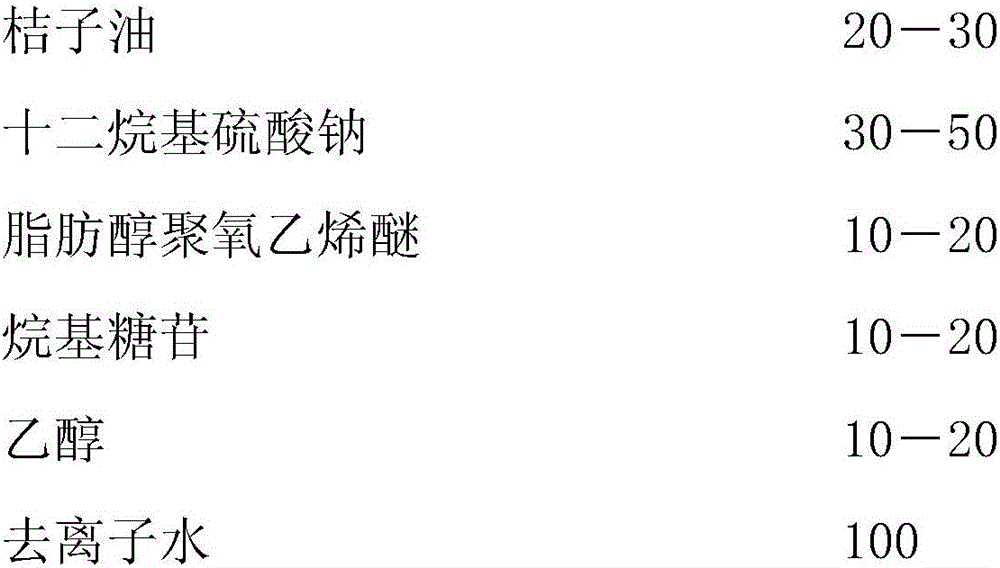

[0020] The cleaning agent used in the off-position ultrasonic cleaning method for heat exchangers of aircraft air-conditioning systems provided by this embodiment consists of the following raw materials in parts by weight:

[0021]

[0022] The cleaning method is to inject the above cleaning agent into the cleaning tank, and then add citric acid to adjust the pH value of the cleaning agent to 5. The citric acid can well react with metal ions and adhere to the surface of the aluminum alloy. Play a certain corrosion inhibition effect, then put the heat exchanger to be descaled into the cleaning tank, soak it with cleaning agent for at least 24 hours, and at the same time supplement it with ultrasonic treatment, the ultrasonic power is 6kW during ultrasonic treatment. Then wash with water for 6 hours.

Embodiment 2

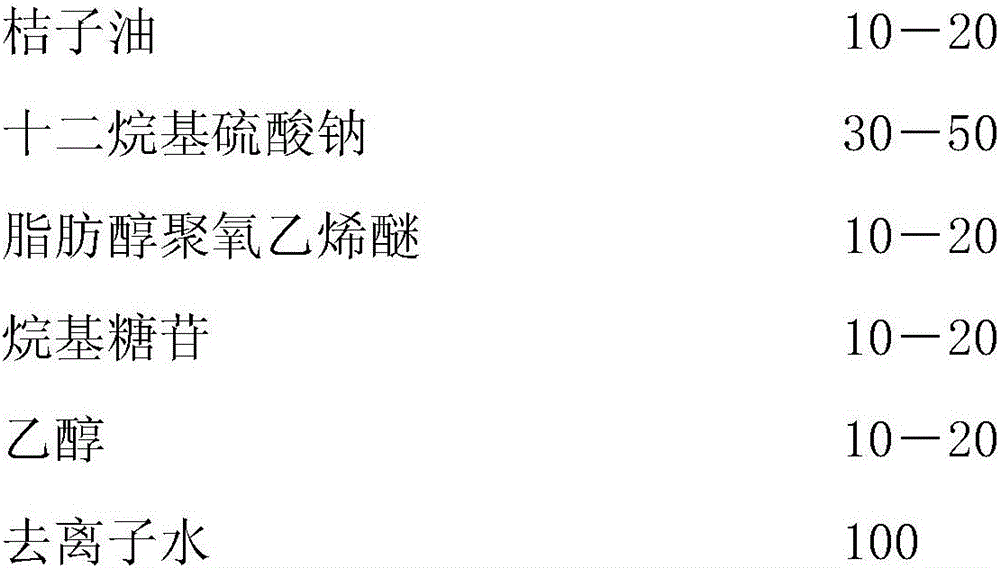

[0024] The cleaning agent used in the off-position ultrasonic cleaning method for heat exchangers of aircraft air-conditioning systems provided by this embodiment consists of the following raw materials in parts by weight:

[0025]

[0026] The cleaning method is to inject the above-mentioned cleaning agent into the cleaning tank, then add citric acid to adjust the pH value of the cleaning agent to 5, then put the heat exchanger to be descaled into the cleaning tank, and use the cleaning agent to soak for at least 24 hours, supplemented by ultrasonic treatment, the ultrasonic power is 6kW during ultrasonic treatment. Finally rinse with water for 12 hours.

Embodiment 3

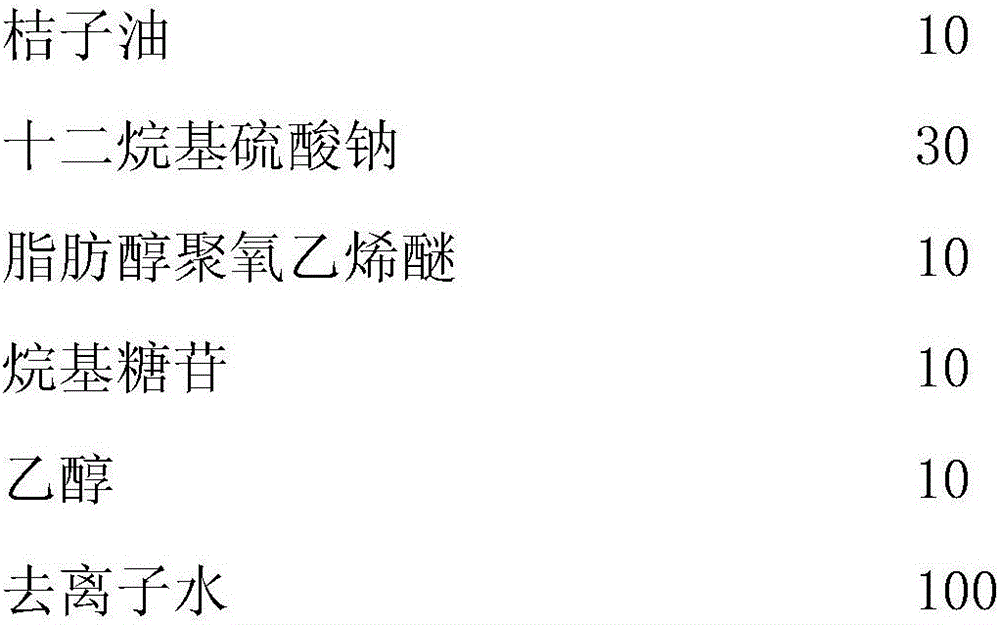

[0028] The cleaning agent used in the off-position ultrasonic cleaning method for heat exchangers of aircraft air-conditioning systems provided by this embodiment consists of the following raw materials in parts by weight:

[0029]

[0030] The cleaning method is to inject the above-mentioned cleaning agent into the cleaning tank, then add citric acid to adjust the pH value of the cleaning agent to 5, then put the heat exchanger to be descaled into the cleaning tank, and use the cleaning agent to soak for at least 24 hours, supplemented by ultrasonic treatment, the ultrasonic power is 6kW during ultrasonic treatment. Finally rinse with water for 9 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com