Compensator, in particular for motor vehicle applications

A compensator and motor vehicle technology, applied in the field of compensators, to achieve the effects of high temperature resistance, high elastic modulus, and small fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

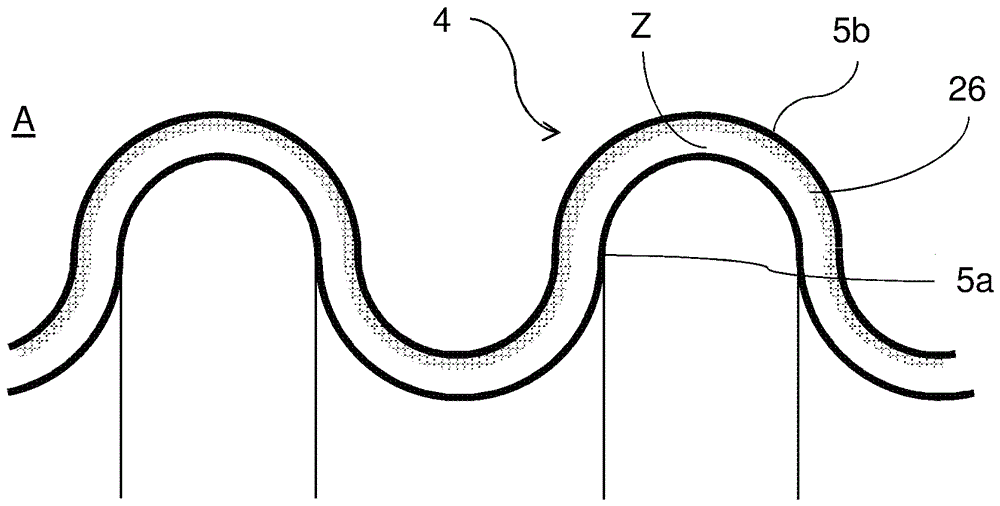

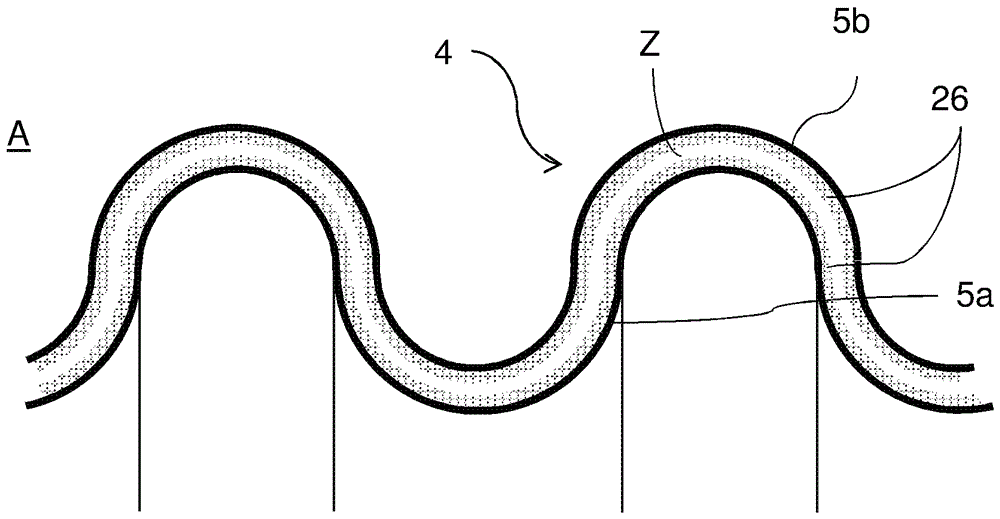

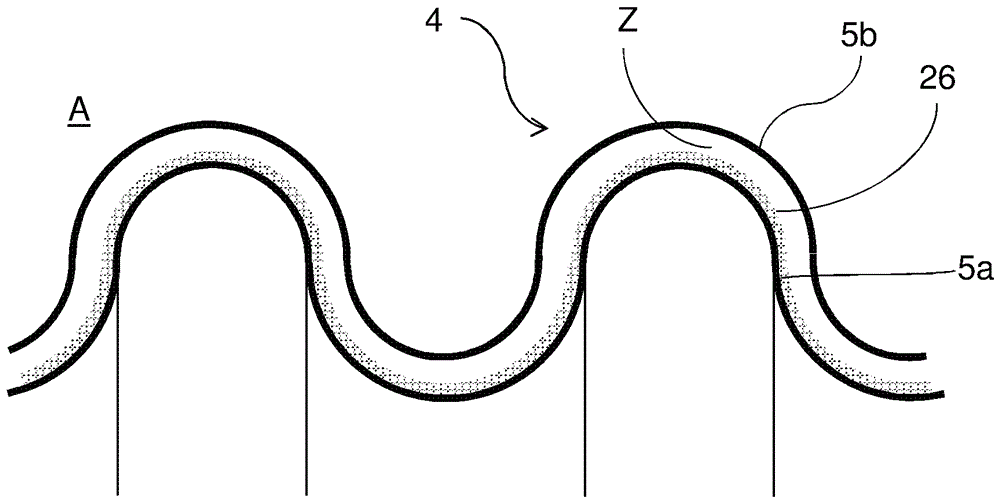

[0038] exist figure 1 shows a schematic cross-sectional view of a compensator 1 which can be used, for example, as an exhaust gas compensator in an exhaust gas recirculation line. The compensator 1 comprises a corrugated or annular corrugated metal bellows 4 . Furthermore, the compensator comprises two conduit connections 2 and 3 for forming a flange connection via which the compensator 1 is installed in a line, for example an exhaust gas recirculation line (not shown).

[0039] In the embodiment shown, the bellows 4 comprises an inner metal layer 5 a and an outer metal layer 5 b , which together form the corrugated wall of the metal bellows 4 . A gap Z is formed between the inner metal layer 5 a and the outer metal layer 5 b into which a friction reducer of a friction-reducing solid is introduced in the form of a continuous intermediate layer 6 extends over the entire length of and adjoins line connections 2 and 3.

[0040] A step in the manufacture of a compensator usuall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com