A kind of bioactive porous ceramic tubular rod, preparation method and application thereof

A porous ceramic, bioactive technology, applied in the field of medical biomaterials, can solve problems such as slow degradation, and achieve the effect of promoting vascularization, reducing chronic inflammatory response, and excellent bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

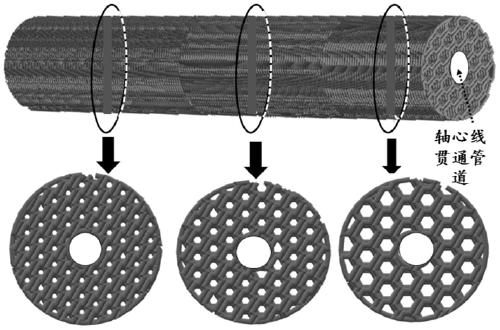

[0060] 1) Put the diopside powder into a ball mill and mill it for 6 hours, then sieve it to obtain an ultrafine powder with a particle size of less than 60 μm, and then stir and disperse the ultrafine powder at a solid-to-liquid mass ratio of 1:2 to a concentration of In 6% polyvinyl alcohol aqueous solution, a two-phase uniform paste is formed, and then the paste slurry is placed in the injection reservoir of the write-in 3D printer, and the shape of the honeycomb channel is set (as attached figure 1 ), the diameter of the central hole channel is 2.6mm, the diameter of the bar is 42mm, and the porosity is set to 24%, 50% and 84% respectively according to 50%, 30% and 20% of the length of the bar, start the printing equipment, press Carry out three-dimensional printing to form a tubular porous rod with an outer diameter and an inner diameter of 42mm and 2.6mm respectively, then dry the tubular porous rod at 60°C for 12 hours, and sinter at 1300°C for 4 hours to obtain a porous...

Embodiment 2

[0065]The preparation method is the same as in Example 1, the difference is that in step 1), the superfine powder is stirred and dispersed into the polyvinyl alcohol aqueous solution with a concentration of 3% at a solid-to-liquid mass ratio of 1:1, and 55% of the length of the rod is used. , 30% and 15% respectively set the porosity to 21%, 55% and 81%, start the printing equipment, press to perform three-dimensional printing, and form a tubular porous rod with an outer diameter and an inner diameter of 42mm and 11.2mm respectively, and obtain after sintering Diopside porous ceramic tubes with outer diameter and inner diameter of 40mm and 10mm respectively; the raw material composition for preparing the calcium magnesium silicate modification layer in step 2) is adjusted to: 0.1mol ethyl orthosilicate is dissolved in 1000ml deionized water , then add 1ml of nitric acid and stir for 15 minutes, then add 0.7mol calcium nitrate and 0.1mol magnesium nitrate, stir and hydrolyze for...

Embodiment 3

[0067] The preparation method is the same as in Example 1, the difference being that the porosity is set to 35%, 50% and 65% respectively according to 65%, 20% and 15% of the rod length in step 1), and the calcium prepared in step 2) The raw material composition of the magnesium silicate modified layer was adjusted as follows: dissolve 0.40mol tetraethyl orthosilicate in 90ml deionized water, add 2ml nitric acid and stir for 15 minutes, then add 0.4mol calcium nitrate and 0.016mol magnesium nitrate, Under stirring and hydrolysis for 60 minutes, aging for 24 hours, the mixed solution is converted into a hydrogel, the diopside porous ceramic tube prepared in step 1) is placed in the gel, immersed in negative pressure suction, and the porous ceramic tubular rod is taken out , and then use vacuum filtration to suck out the excess gel in the pores, continue to age for 36 hours, dry at 95°C for 36 hours, calcinate at 950°C for 2 hours, and cool naturally. After testing, the minimum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com