Autoclave plaster brick and preparation method thereof

A gypsum block and autoclaved technology, which is applied in the field of autoclaved gypsum block and its preparation, can solve the problem of low dosage of phosphogypsum, achieve the effects of reducing land occupation and environmental pollution, good quality, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

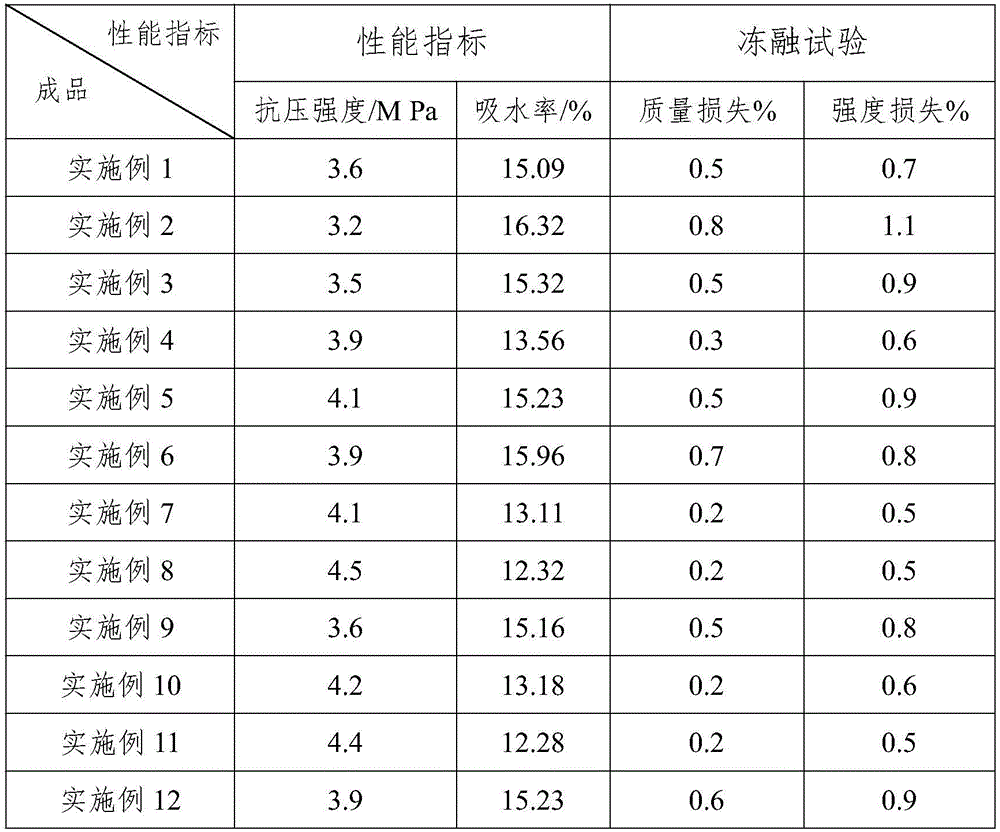

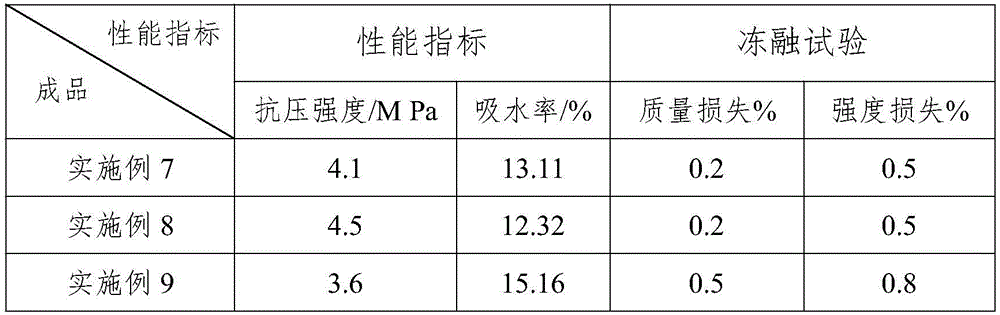

Examples

Embodiment 1

[0032] The autoclaved gypsum block of this embodiment includes the following raw materials in weight percentage: phosphogypsum 30%, carbide slag 6%, fly ash 20%, aggregate 25%, slag ash 4%, composite activator 15%, composite activator It is a mixture of silica fume and sulfate solution, wherein the mass ratio of silica fume and sulfate solution is 2:0.6.

[0033] Wherein the preparation method of the composite activator is: add the silica fume and the sulfate solution into a mixer at the same time, mix and stir evenly, and the stirring time is 5 minutes to obtain a mixed material, and then send the mixed material into a digestion bin for storage It can be digested for 0.5 hours, and the water content is controlled to 6%.

[0034] According to the percentage by weight of the raw materials of this embodiment, the preparation method of the autoclaved gypsum block comprises the following steps:

[0035] S1. Weigh each raw material according to the percentage by weight of the raw ...

Embodiment 2

[0039] The autoclaved gypsum block of this embodiment includes the following raw materials in weight percentage: phosphogypsum 65%, carbide slag 6%, fly ash 12%, aggregate 5%, slag ash 2%, composite activator 10%, composite activator It is a mixture of silica fume and sulfate solution, wherein the mass ratio of silica fume and sulfate solution is 5:1.5.

[0040] Wherein the preparation method of the composite activator is as follows: the silica fume and the sulfate solution are added to the mixer at the same time, mixed and stirred evenly, and the stirring time is 8 minutes to obtain the mixed material, and then the mixed material is sent into the digestion chamber for storage It can be digested for 2 hours, and the water content is controlled to 8%.

[0041] According to the percentage by weight of the raw materials of this embodiment, the preparation method of the autoclaved gypsum block comprises the following steps:

[0042] S1. Weigh each raw material according to the pe...

Embodiment 3

[0046] The autoclaved gypsum block of this embodiment includes the following raw materials in weight percentage: phosphogypsum 60%, carbide slag 18%, fly ash 10%, aggregate 5%, slag ash 2%, composite activator 5%, composite activator It is a mixture of silica fume and sulfate solution, wherein the mass ratio of silica fume and sulfate solution is 2:1.5.

[0047] Wherein the preparation method of the composite activator is: add the silica fume and the sulfate solution into a mixer at the same time, mix and stir evenly, and the stirring time is 6 minutes to obtain a mixed material, and then send the mixed material into a digestion bin for storage It can be digested for 1 hour, and the water content is controlled to 7%.

[0048]According to the percentage by weight of the raw materials of this embodiment, the preparation method of the autoclaved gypsum block comprises the following steps:

[0049] S1. Weigh each raw material according to the percentage by weight of the raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com