The method to eliminate the low temperature failure of the anti-skid brake control device

A technology of control devices and anti-skid brakes, which is applied to ground devices, transportation and packaging, aircraft parts, etc. point cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

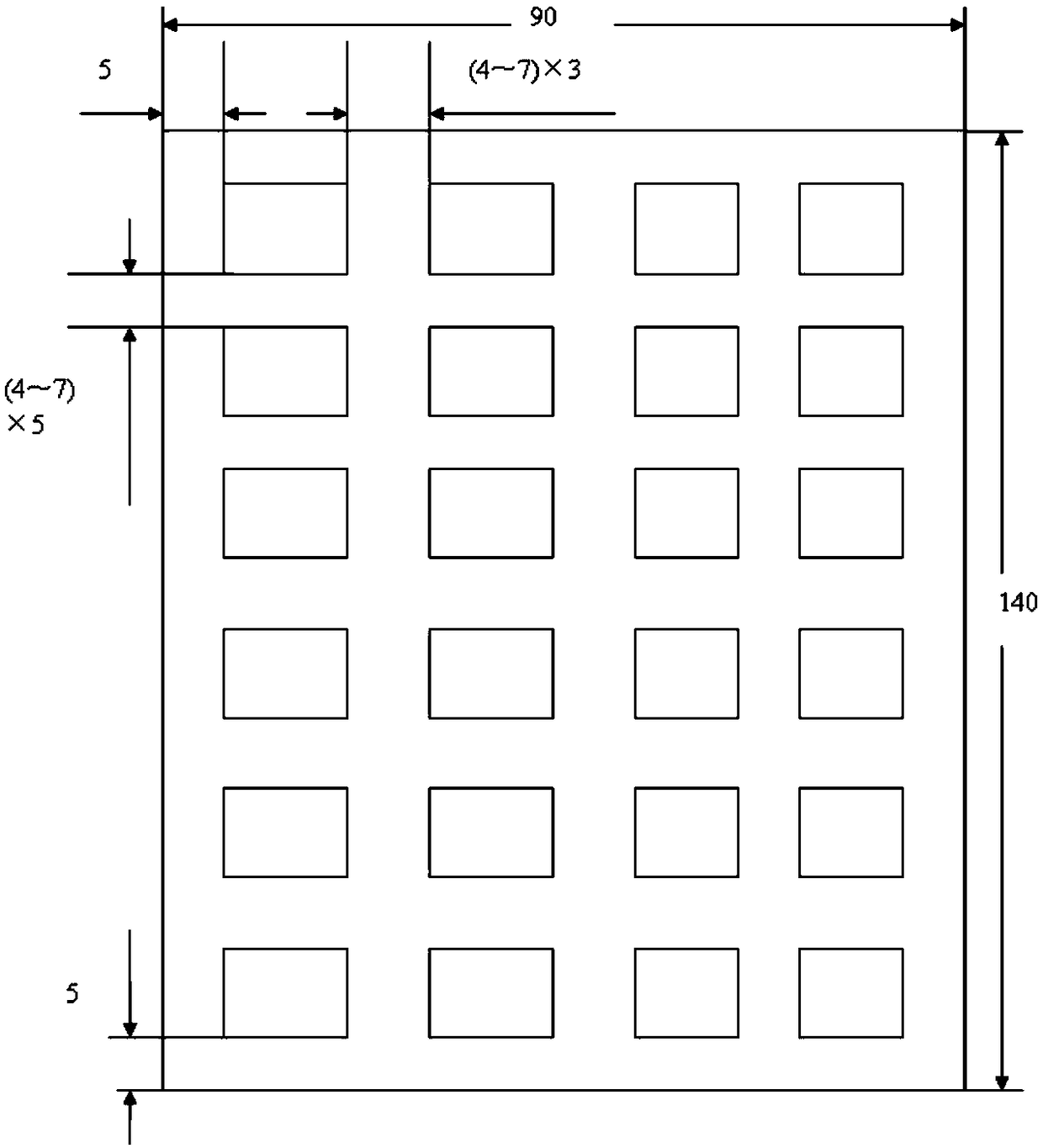

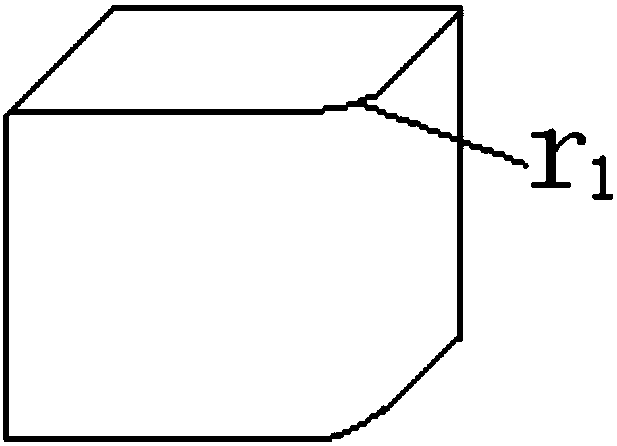

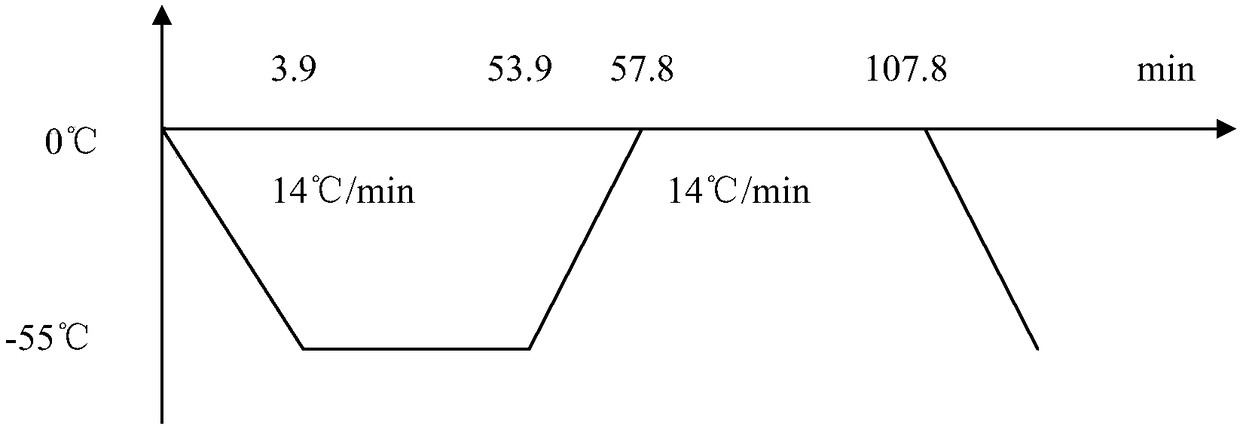

[0082] This embodiment is a method for eliminating the low-temperature failure of the civil aircraft anti-skid brake control device. The anti-skid brake control device is a closed shell, and the low temperature of the selected components is -55°C. When the ambient temperature reaches -55°C, if the temperature of the low-power components is lower than -45°C, the anti-skid brake control can be controlled under long-term low temperature conditions. The unit will malfunction under low temperature. In order to improve the low temperature resistance capability of the antiskid brake control device, corresponding structural improvements are made.

[0083] In the invention with the application number 201610876780.5, a method for determining the low-temperature weak link of the anti-skid brake control device is disclosed. In this method, it is proposed that under the condition of the ambient temperature of -55°C, the components with a temperature lower than -45°C are low-temperature we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com