Application of copper alginate

A technology of copper alginate and sodium alginate, which is applied in the direction of fatty acid production, fatty acid esterification, fatty acid chemical modification, etc., can solve the problems of unfavorable promotion and use, harsh preparation conditions, low catalytic activity, etc., and achieve low synthesis cost and preparation Simple process and high reactivity

Inactive Publication Date: 2017-01-18

ANSHUN UNIV

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, there have been some basic studies on heterogeneous acid catalysts such as solid superacids, supported solid acids, metal oxides and their complexes, molecular sieves, cation exchange resins, ionic liquids, and heteropolyacids, but most of them have catalytic activity. It is relatively low, and it needs to be reacted at high temperature and pressure for a long time to show good activity, and the preparation conditions of heterogeneous acids such as solid superacids and molecular sieves are harsh and the cost is high; while heteropoly acids, ionic liquids and other heterogeneous acids are expensive to purchase, And it is easy to form a liquid phase system with the solution, so it is not suitable for industrial promotion and use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

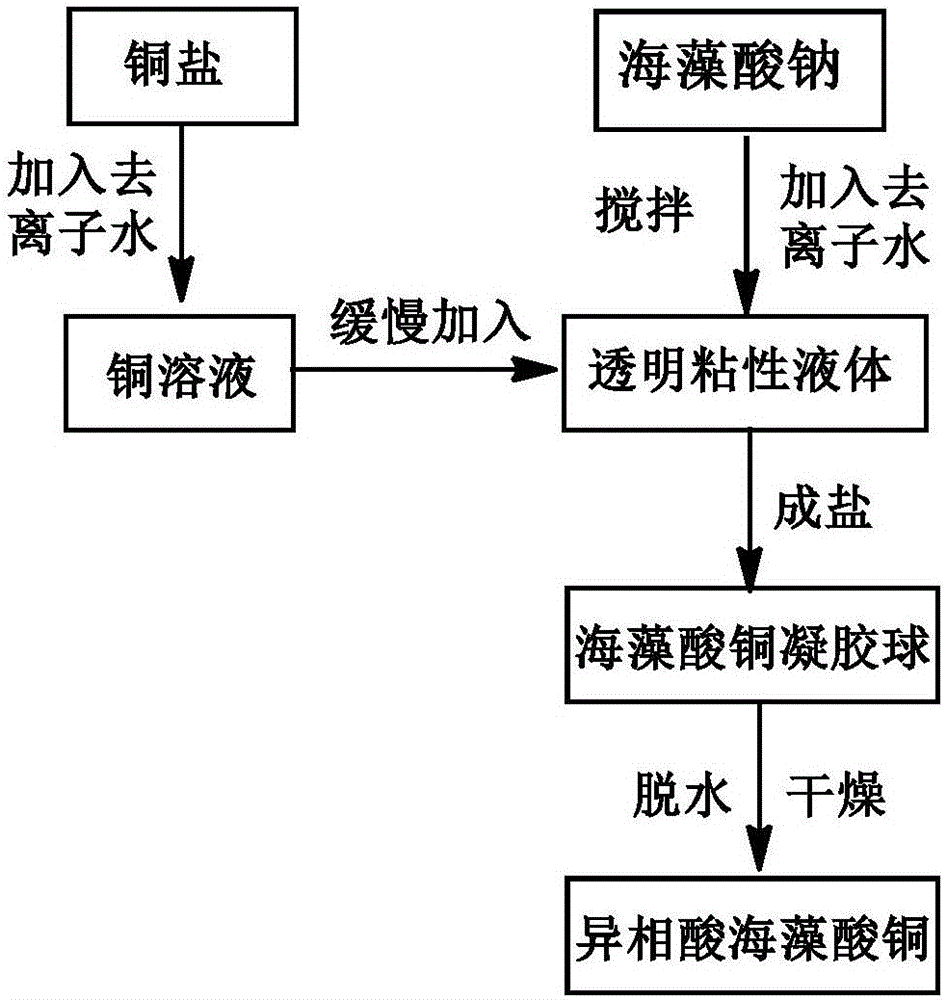

[0033] One, the preparation of copper alginate:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

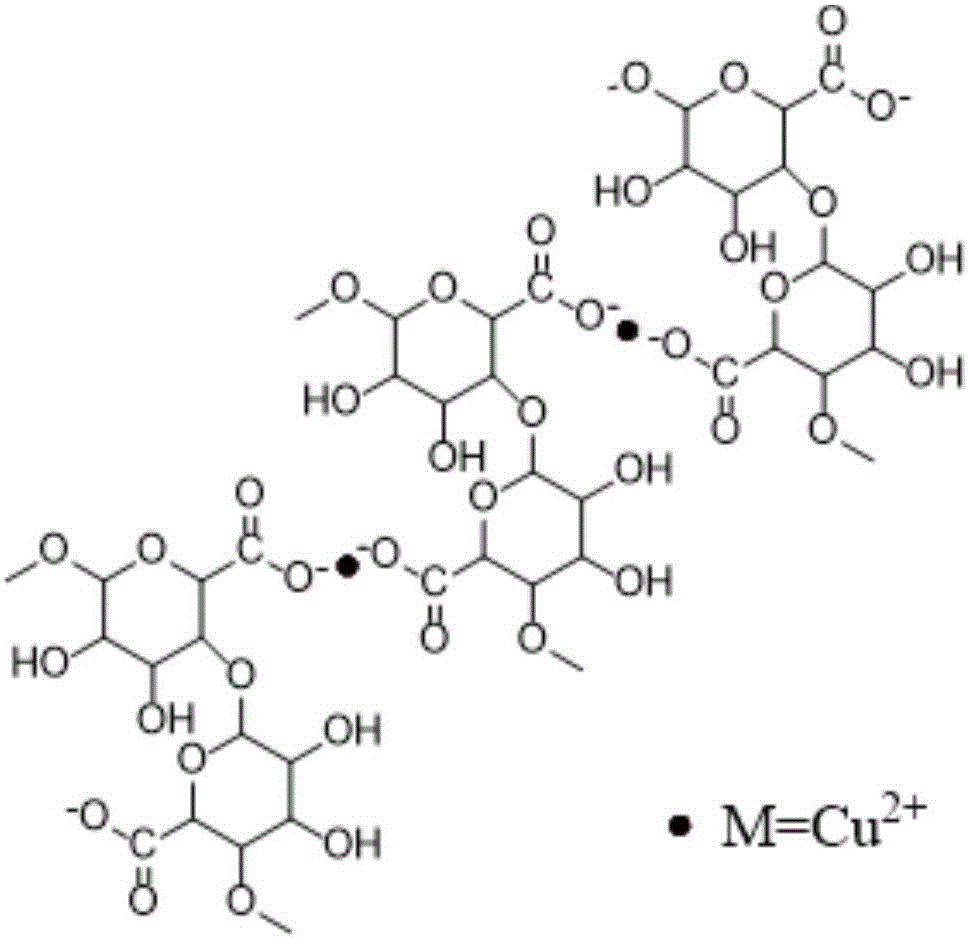

The invention belongs to the technical field of copper alginate application and particularly relates to application of copper alginate in various fatty acid esterification reactions. The copper alginate serves as a catalyst to be applied to various fatty acid esterification reactions. The catalyst copper alginate uses biopolymer sodium alginate as a raw material, the sodium alginate is wide in source, low in price, non-toxic and environmentally friendly a preparation process is simple, the synthesis cost is lower, the reaction activity is higher, no corrosion is produced on a production device in the using process, and no adverse effect is produced on the environment. The catalyst copper alginate can also show better esterification catalyzing activity under the conditions of mild catalytic conditions and shorter reaction time. The catalyst copper alginate is used for esterification reaction, the demanded quantity is small, the operation of separating products and copper alginate is simple and convenient, and the copper alginate can be recycled and is suitable for industrial popularization and usage, and the costs are reduced.

Description

technical field [0001] The invention belongs to the technical field of application of copper alginate, and in particular relates to the application of copper alginate in fatty acid esterification. Background technique [0002] With the rapid development of the world economy, the global petrochemical resources are increasingly depleted, and the fuel supply situation is becoming increasingly severe; on the other hand, the exhaust gas (such as sulfur oxides, carbon dioxide, etc.) deterioration. Therefore, the development and utilization of sustainable alternative fuels has become a research hotspot all over the world, among which esterification and transesterification to convert oil to biodiesel is an economically feasible route. At present, the preparation of biodiesel (long-chain fatty acid methyl esters) mostly uses homogeneous acids (H2SO4, H3PO4) or homogeneous bases (KOH, NaOH) as catalysts for catalytic preparation, and the use of homogeneous catalysts has a faster reac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

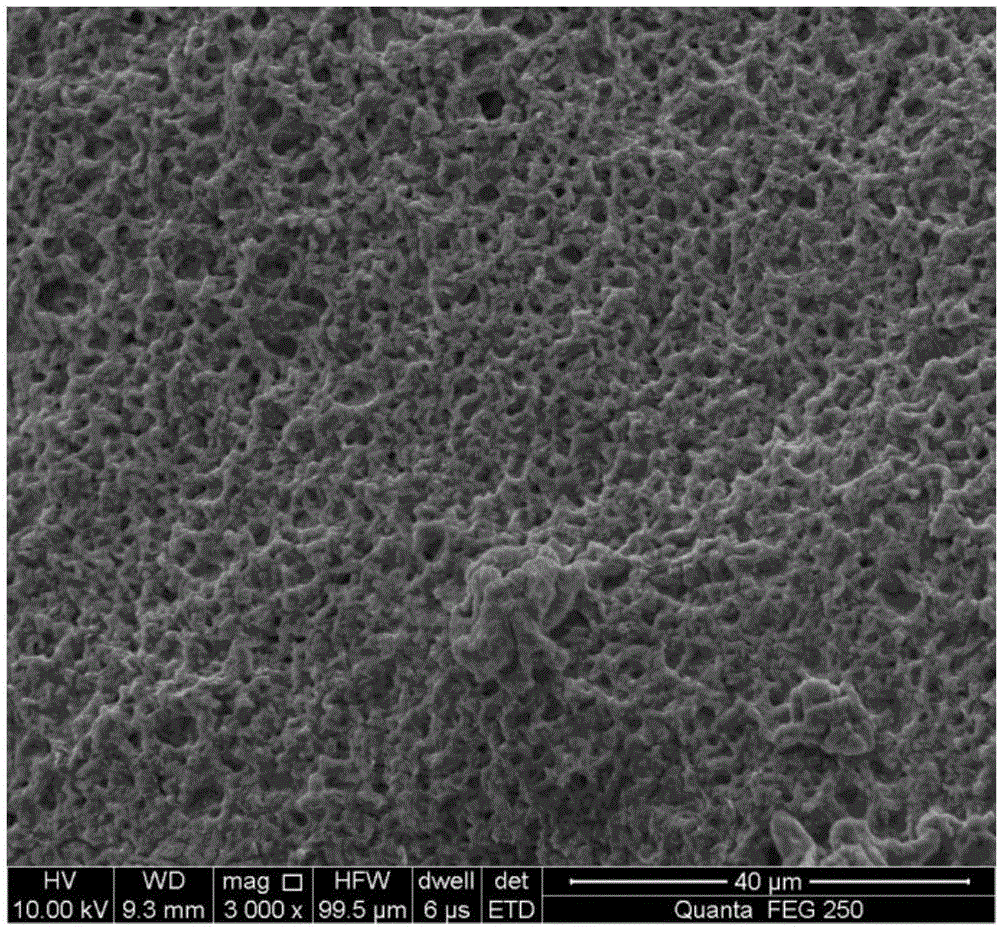

Login to View More IPC IPC(8): C11C3/00B01J31/12B01J35/04

CPCC11C3/003B01J31/123B01J35/56

Inventor 张秋云魏方方张玉涛韦复华陈红亮崔红彦

Owner ANSHUN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com