A method for pulverizing food particles

A food material and granule technology, which is applied in grain processing and other directions, can solve problems such as food material damage, nutrient loss, discoloration and taste change, and achieve the effect of improving work efficiency and expanding horizontal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

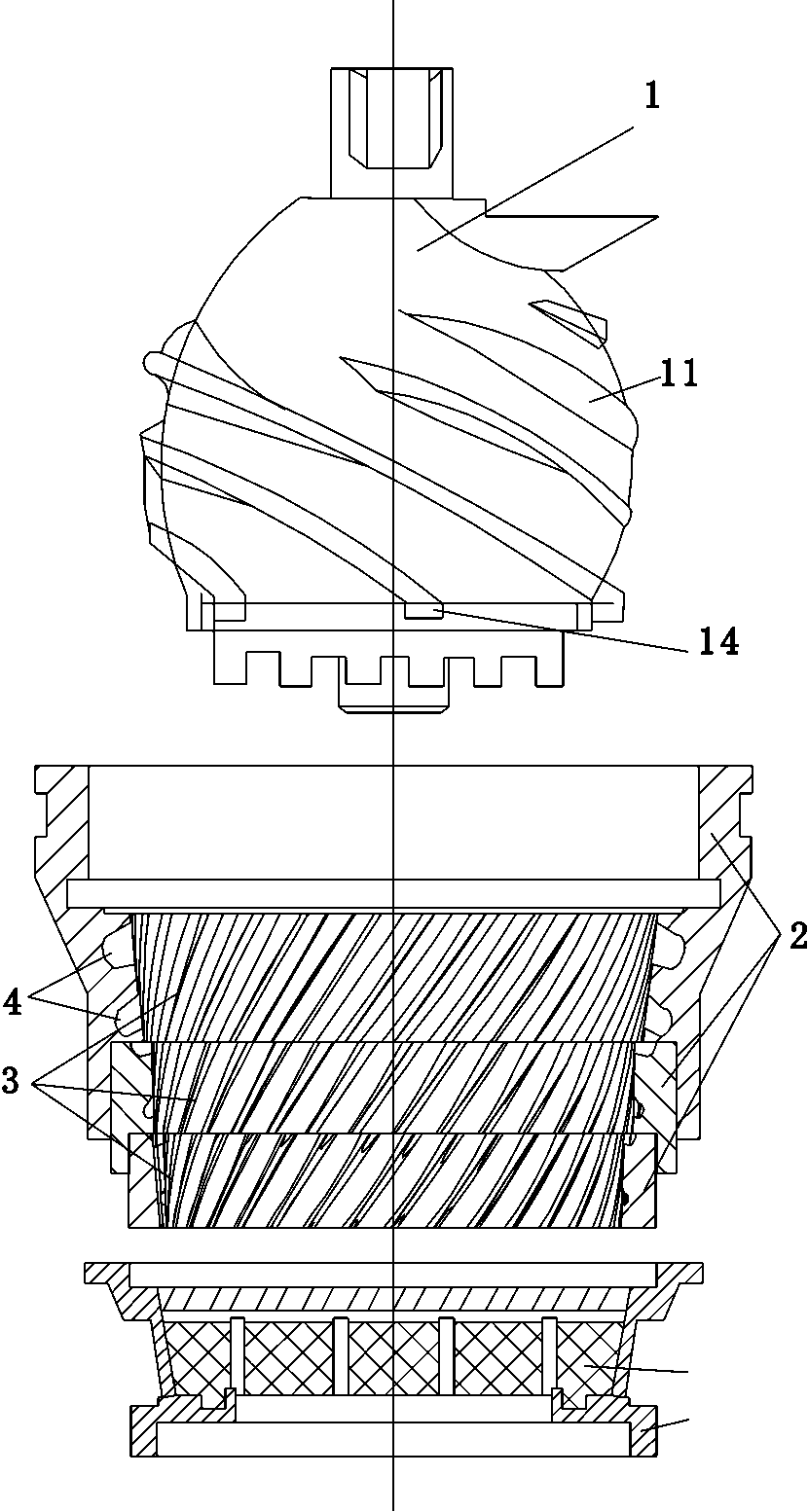

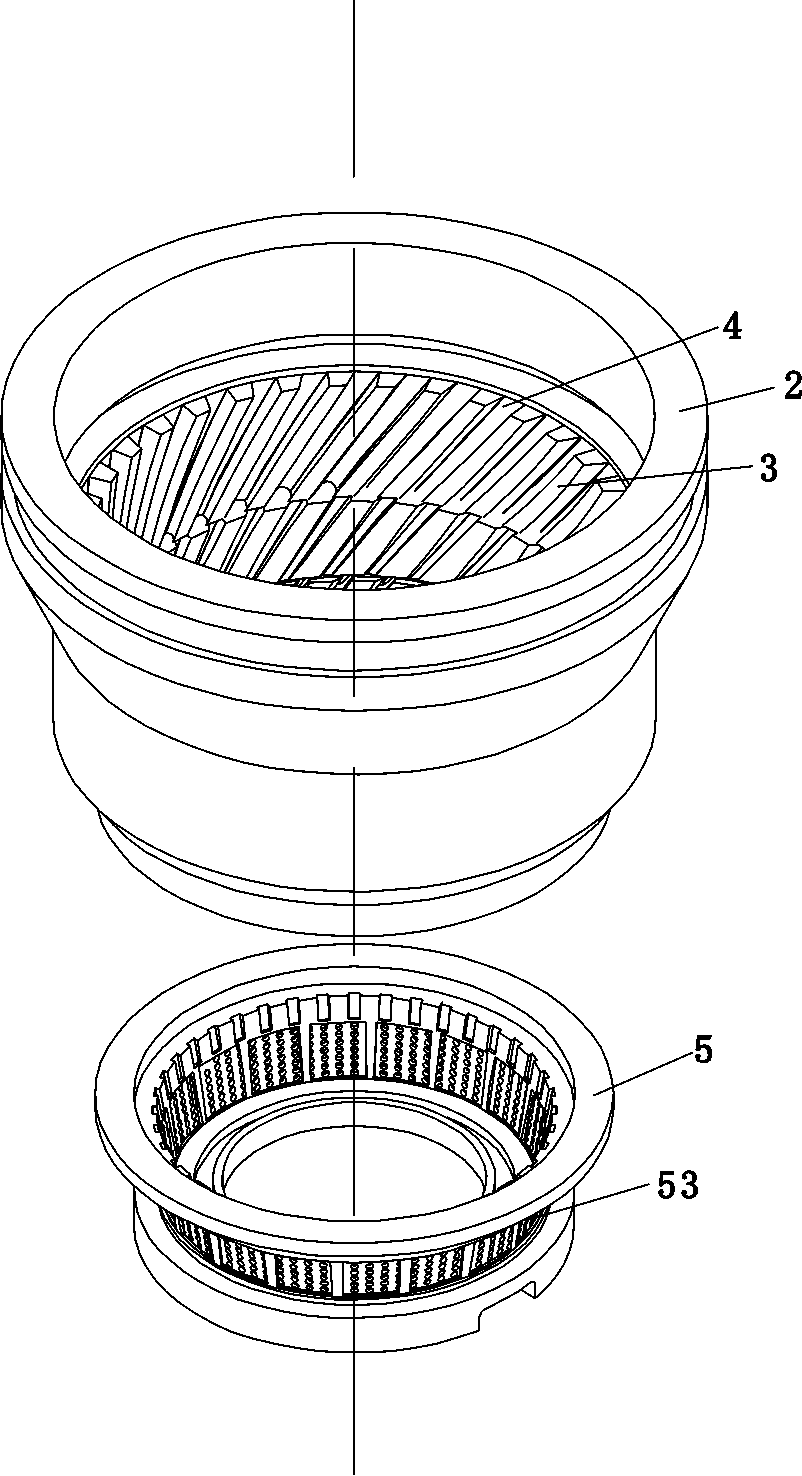

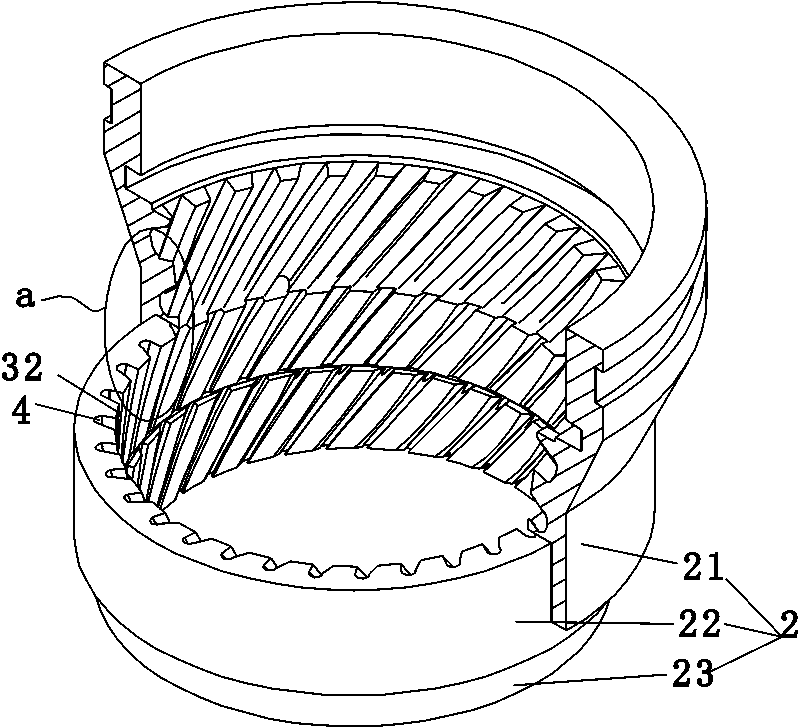

[0045] see Figure 1-4 , including a spinning cone-shaped screw 1 that vertically rotates and squeezes food materials and runs downward, and a grinding disc 2 that is sheathed outside the screw 1 and cooperates with the screw 1 to rotate in reverse. The rotating grinding disc 2 is provided with at least one layer of cutter rings. The cutter rings include several strip-shaped cutting knives 3 intersecting with the protruding lines 11 of the screw rod 1. The cutting knives 3 are preferably evenly arranged. An inclined sipe is provided or directly formed between the two cutting knives 3, and the sipe grooves of adjacent layers of knife rings can be connected. The lower part is sealed to prevent food particles from leaking out of the knife groove.

[0046]The depth of the sipes of the same layer of cutter rings is generally less effective in degraining. As a preference, the depth of the sipes should gradually become shallower from top to bottom, that is, the bottom of the sipes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com