Adsorbent used for blood or plasma perfusion to remove endotoxin and preparation method thereof

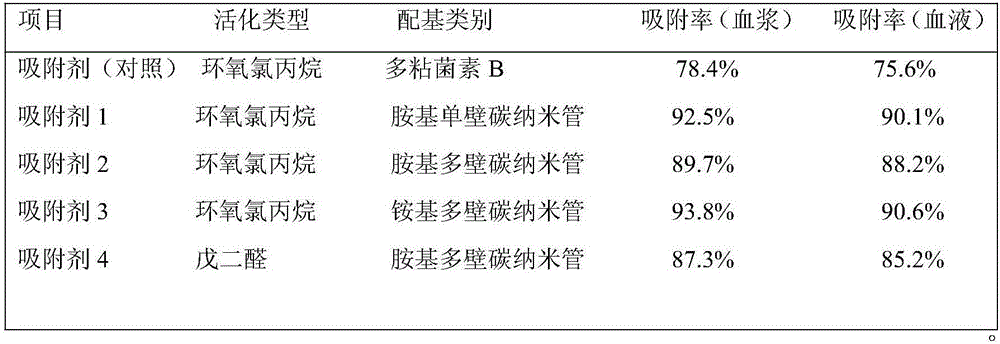

A plasma perfusion and adsorbent technology, applied in the field of biomedicine, can solve the problems of practical application obstacles, small amount of ligand coupling, increased risk, etc., achieve high mechanical strength and physical and chemical stability, improve adsorption capacity, and excellent adsorption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of carrier microspheres

[0031] Add 15g of vinyl acetate, 30g of triallyl ethyl cyanurate, 15ml of ethyl acetate and 30ml of n-heptane into 2000ml of Sankouping, heat up to 30°C, stir well and add 0.9g of azobisisobutyl Cyanide, add 1500ml aqueous solution (containing 0.5% polyvinyl alcohol and 10% sodium chloride) after dissolving, adjust the stirring speed to make the droplets reach a suitable size and disperse evenly, heat up to 65°C, keep warm for 2 hours, and then heat up to 85°C ℃ for 2 hours, and filtered to obtain a white spherical polymer. The white spherical polymer was thoroughly washed with water and ethanol in turn, and dried in the air. Add the above dried white spherical polymer into 2% NaOH methanol solution, and carry out alcoholysis reaction at 40°C for 12 hours. After the reaction, suction filter, fully wash with methanol, and dry to obtain the desired carrier microspheres. The carrier microspheres have a particle size of 150-450um,...

Embodiment 2

[0037] (1) Preparation of carrier microspheres

[0038] Add 20g of vinyl acetate, 5g of triallyl ethyl cyanurate, 20ml of ethyl acetate and 20ml of n-heptane into 1500ml of Sankouping, heat up to 45°C, stir well and add 0.5g of azobisisobutyl Cyanide, after dissolving, add 1000ml aqueous solution (containing 1.0% polyvinyl alcohol and 5% sodium chloride), adjust the stirring speed to make the droplets reach a suitable size and disperse evenly, heat up to 75°C, keep warm for 4 hours, and then heat up to 90°C °C for 3 hours, filter the white spherical polymer. The white spherical polymer was thoroughly washed with water and ethanol in turn, and dried in the air. Add the above dried white spherical shape into 2% NaOH methanol solution, and carry out alcoholysis reaction at 45°C for 24 hours. After the reaction is completed, suction filter, fully wash with methanol, and dry to obtain the desired carrier microspheres. The particle size of the carrier microsphere is 200-400um, the...

Embodiment 3

[0044] (1) Preparation of carrier microspheres

[0045] Add 15g of vinyl acetate, 15g of triallyl ethyl cyanurate, 25ml of ethyl acetate and 10ml of n-heptane into 1500ml of Sankouping, heat up to 40°C, stir well and add 0.3g of azobisisobutyl Cyanide, add 1000ml of aqueous solution (containing 1.5% polyvinyl alcohol and 3% sodium chloride) after dissolving, adjust the stirring speed to make the droplets reach a suitable size and disperse evenly, heat up to 65°C, heat-preserve and polymerize for 6 hours, then heat up to 95°C °C for 4 hours, filter the white spherical polymer. The white spherical polymer was thoroughly washed with water and ethanol in turn, and dried in the air. Add the dried white spheres into 2% methanol solution of NaOH, and carry out alcoholysis reaction at 40°C for 6 hours. After the reaction, filter with suction, fully wash with methanol, and dry in the air to obtain the desired carrier microspheres. The carrier microspheres have a particle size of 250-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com