Method for preparing solvated nanocrystalline thermoelectric thin film through interface control method

A thermoelectric thin film, nanocrystalline technology, applied in the manufacture/processing of thermoelectric devices, nanotechnology for materials and surface science, nanotechnology, etc. The effect of promoting wide application, improving thermoelectric performance, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] This embodiment provides a method for wet chemical synthesis of solvated nanocrystals, the method comprising the following steps:

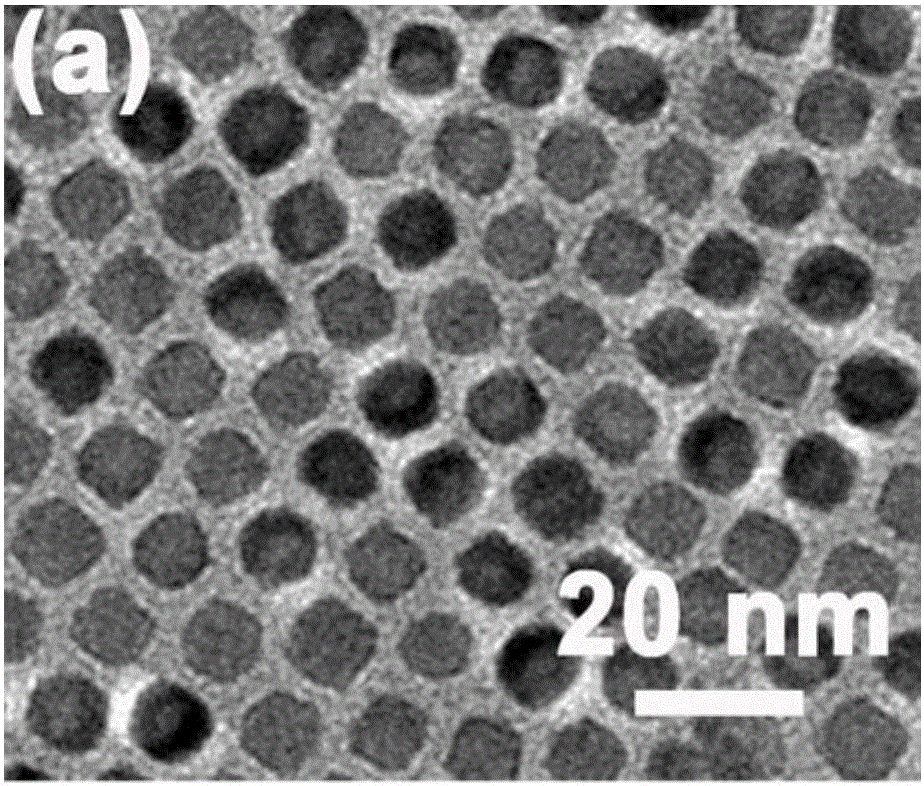

[0102] (1) Preparation of lead telluride (PbTe) nanocrystals:

[0103] Mix 2.5mmol of lead acetate trihydrate, 7.5mmol of oleic acid and 20mL of diphenyl ether evenly, vacuumize and heat at 70°C, and degas at this temperature for 3h. Then nitrogen gas is introduced into the reaction device, and the solution is heated to 180 ° C. At this temperature, 10 mL of TOPTe solution with a concentration of 0.75 M is rapidly injected (in a glove box, tellurium powder is dissolved in n-trioctylphosphine (TOP) solution Middle), the reaction solution was reacted at 155-160° C. for about 2 minutes. The heating was removed and the reactor was cooled to room temperature with a water bath.

[0104] Clean the nanocrystals in the container in an argon glove box, first disperse in 5mL toluene, then precipitate with a mixture of ethanol / acetone, centrifuge at ...

Embodiment 2

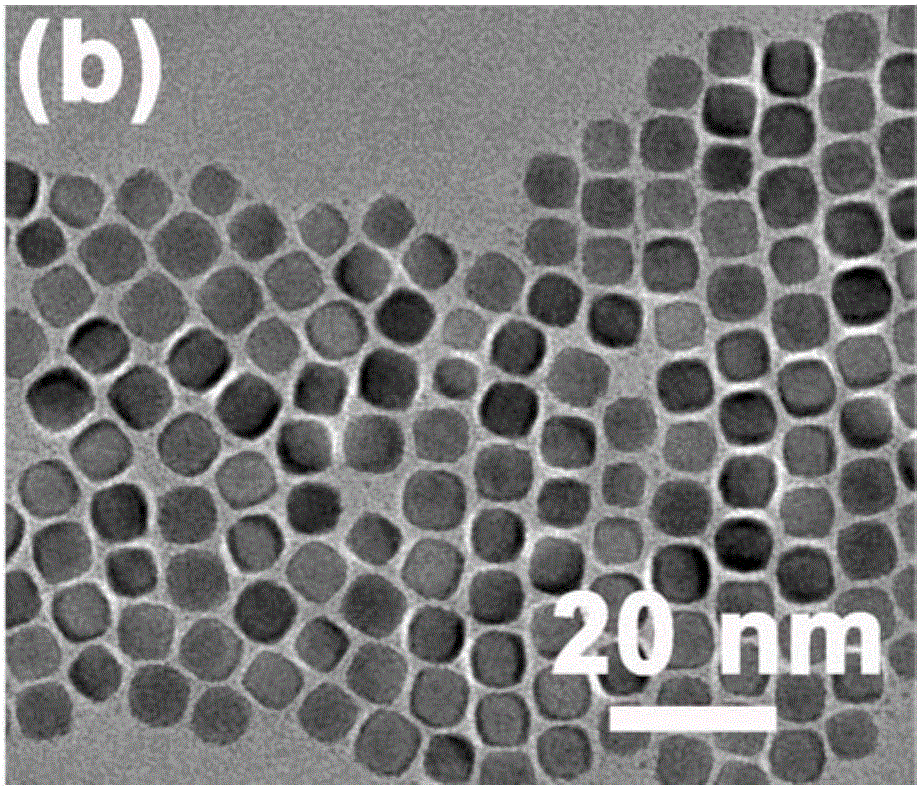

[0113] This embodiment provides a method for preparing a solvated PbTe nanocrystalline thermoelectric film by an interface control method, the method comprising the following steps:

[0114] (1) The PbTe nanocrystalline n-octane solution of 10mg / mL prepared in Example 1 is spin-coated on the substrate for 40s at a speed of 1000rpm to obtain a nanocrystalline film coating;

[0115] (2) Soak the nanocrystalline thin film coating prepared in step (1) in a solution of ethylenediamine acetonitrile with a concentration of 0.1mol / L, and react at a constant temperature of 50°C for 30min under an inert environment to carry out ligand removal reaction, and then Rinse with pure acetonitrile solution and dry;

[0116] (3) Anneal the nanocrystalline film stripped of the original ligand in an argon atmosphere, the annealing temperature is 300 ° C, the annealing time is 40 min, repeat the whole preparation process 3 times, and obtain a solvated PbTe with a thickness of about 50 nm Nanocryst...

Embodiment 3

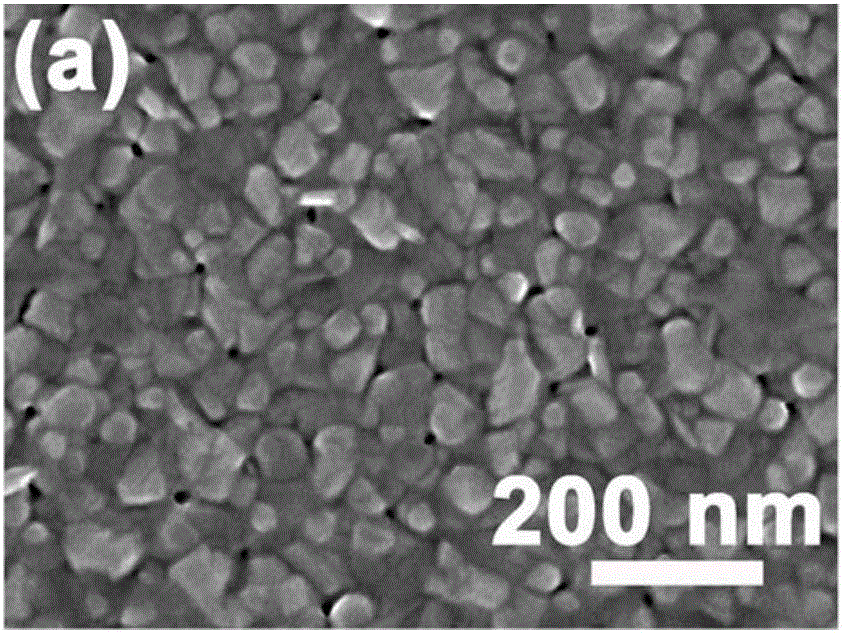

[0119] This embodiment provides a method for preparing solvated PbTe nanocrystalline thermoelectric thin film by interface control method, except that the annealing temperature in step (3) is 350°C, the amount of other materials and the preparation method are the same as those in Example 2 same.

[0120] The thermoelectric properties of the prepared solvated PbTe nanocrystalline thermoelectric thin film are shown in Table 1, and its scanning electron microscope picture is shown in Figure 2(b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com