Method for monitoring corrosion degradation of bioabsorbable implant and for semi-quantification of relative weight loss ratio of corrosion product thereof

A technology for corrosion products and implants, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of patient influence, patient discomfort, and implants that cannot be monitored, and achieve the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

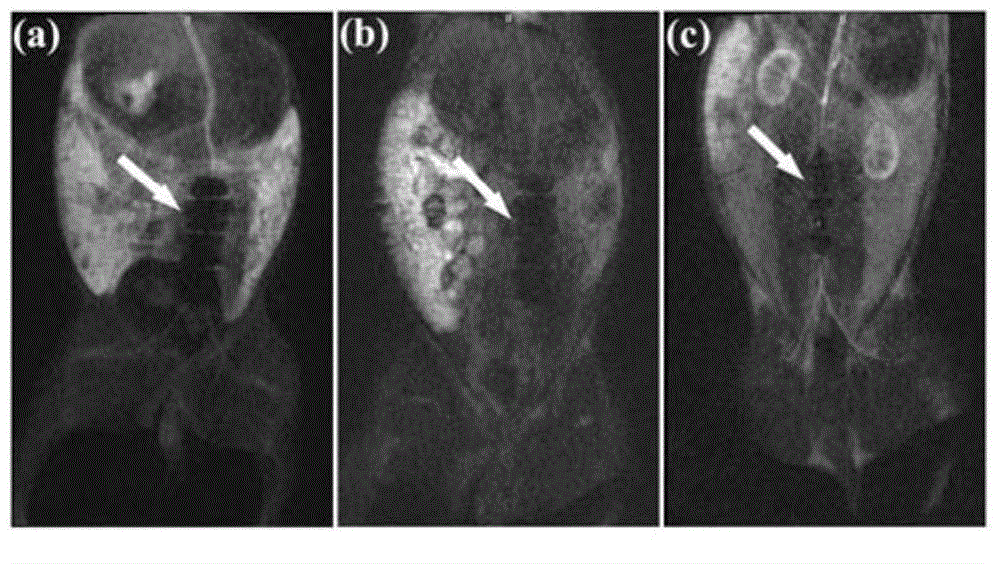

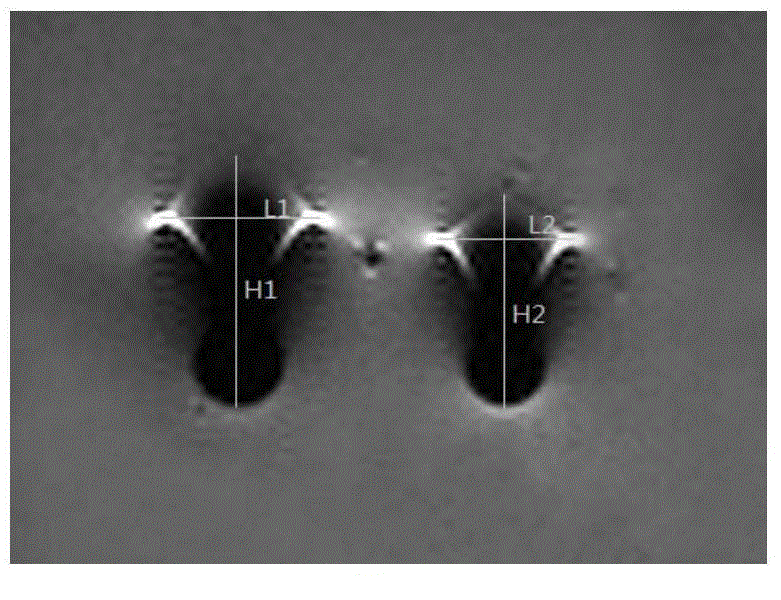

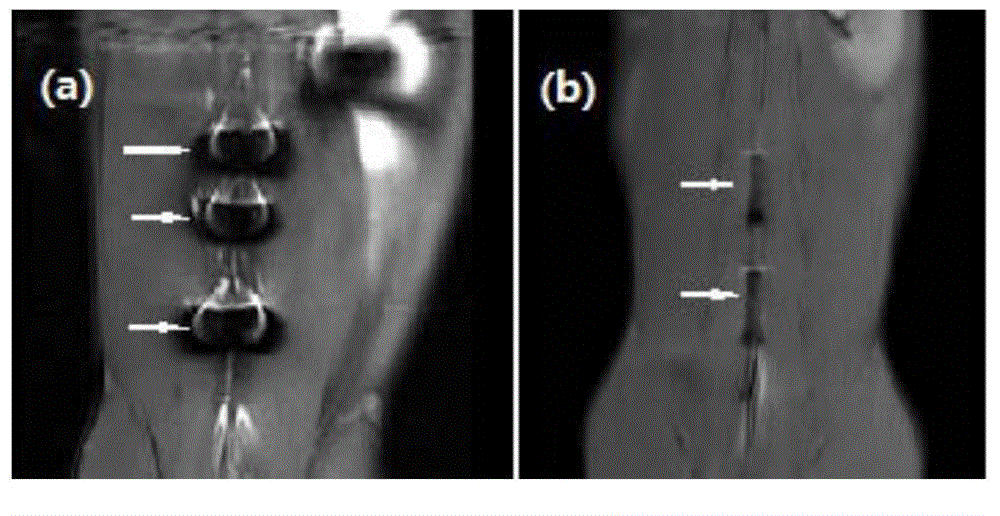

[0030] The invention utilizes nuclear magnetic resonance imaging (MRI) to monitor artifact changes to determine the corrosion degradation of bioabsorbable implants, and is suitable for qualitative monitoring of implants made of magnetic materials, and can also semi-quantitatively calculate the relative weightlessness of implants rate and the relative weight loss rate of its corrosion products. The semi-quantitative calculation of the relative weight loss rate of the implant and the relative weight loss rate of the corrosion product of the implant includes the method for monitoring the corrosion degradation of the magnetic bioabsorbable implant provided by the present invention: The implants or their corrosion products in the individual (i.e. samples) are imaged by MRI at different implantation time points, and any one of the coronal, sagittal or axial planes is selected as the standard plane, and the maximum artifact size of the standard plane is established The function relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com