A desulfurization gypsum putty releasing negative oxygen ions

A technology of desulfurization gypsum and negative oxygen ions, applied in the direction of filling slurry, etc., can solve problems such as single function, no use of desulfurization gypsum characteristics, and inability to exert carrier function, etc., to enhance human muscle energy, facilitate blood oxygen transport, improve The effect of human immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

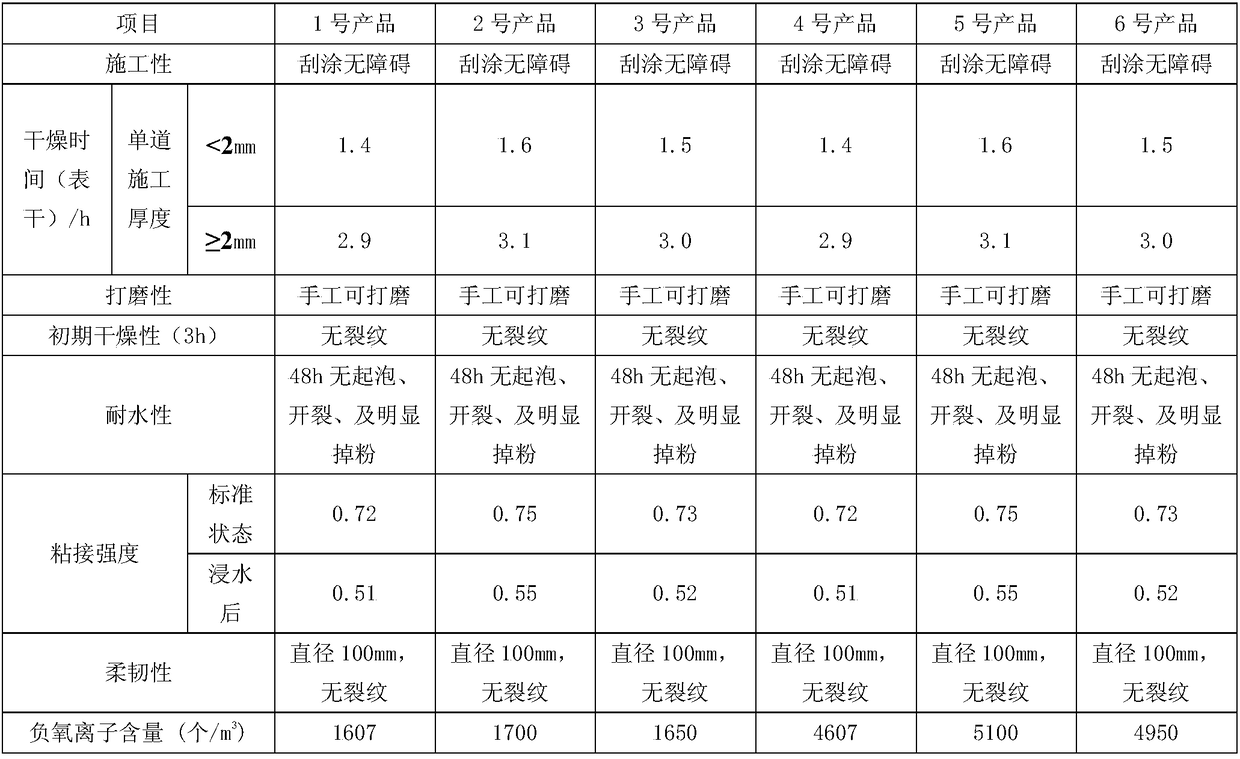

Embodiment 1

[0036] The raw materials are: 40 kg of desulfurized gypsum, 10 kg of sand, 10 kg of talc powder, 10 kg of tourmaline powder, 0.2 kg of composite retarder, 0.2 kg of hydroxypropyl methylcellulose, 0.1 kg of water repellent, 0.01 kg of starch ether, glue 1 kilogram of powder; the particle diameter of sand is 70 meshes, the particle diameter of tourmaline powder is 1200 meshes, the particle diameter of talcum powder is 300 meshes, and the viscosity of hydroxypropyl methylcellulose is 80,000; The weight ratio of citric acid, boric acid, tartaric acid and sodium citrate is 20:20:5:20.

[0037] Weigh the raw materials of the above-mentioned quality for each of the above-mentioned components, then weigh, mix, and stir evenly to remember the product, which is recorded as No. 1 product. When using, add water according to 30-35% of the powder mass and stir until uniform. According to "JG / T 298-2010 Putty for Building Interiors", measure the physical properties of putty. Then close the ...

Embodiment 2

[0039] The raw materials are: 60 kg of desulfurized gypsum, 30 kg of sand, 30 kg of talc powder, 20 kg of tourmaline powder, 0.5 kg of composite retarder, 0.5 kg of hydroxypropyl methylcellulose, 0.5 kg of water repellent, 0.1 kg of starch ether, glue 2 kilograms of powder; the particle diameter of sand is 140 meshes, the particle diameter of tourmaline powder is 1300 meshes, the particle diameter of talc powder is 350 meshes, and the viscosity of hydroxypropyl methylcellulose is 80,000; The weight ratio of citric acid, boric acid, tartaric acid and sodium citrate is 40:40:15:40.

[0040] Weigh the raw materials of the above-mentioned quality for each of the above-mentioned components, then weigh, mix, and stir evenly to remember the product, which is recorded as No. 2 product. When using, add water according to 30-35% of the powder mass and stir until uniform. According to "JG / T 298-2010 Putty for Building Interiors", measure the physical properties of putty. Then close the ...

Embodiment 3

[0042] The raw materials are: 50 kg of desulfurized gypsum, 20 kg of sand, 20 kg of talc powder, 15 kg of tourmaline powder, 0.35 kg of composite retarder, 0.35 kg of hydroxypropyl methylcellulose, 0.3 kg of water repellent, 0.05 kg of starch ether, glue 1.5 kilograms of powder; the particle diameter of sand is 100 mesh, the particle diameter of tourmaline powder is 1250 mesh, the particle diameter of talcum powder is 325 mesh, and the viscosity of hydroxypropyl methylcellulose is 70,000; The weight ratio of citric acid, boric acid, tartaric acid and sodium citrate is 30:30:10:30.

[0043] Weigh the raw materials of the above-mentioned quality for each of the above components, then weigh, mix, and stir evenly to remember the product. According to "JG / T 298-2010 Putty for Building Interiors", measure the physical properties of putty. Then close the doors and windows, and use the negative oxygen ion detector to detect the content of negative oxygen ions in the room after 15 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com