High-performance cationic rosin size and preparation method thereof

A cationic rosin glue, high-performance technology, applied in the direction of rosin addition, hydrophobic agent addition, etc., can solve the problems of difficult emulsification, high melting point, strong interaction, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

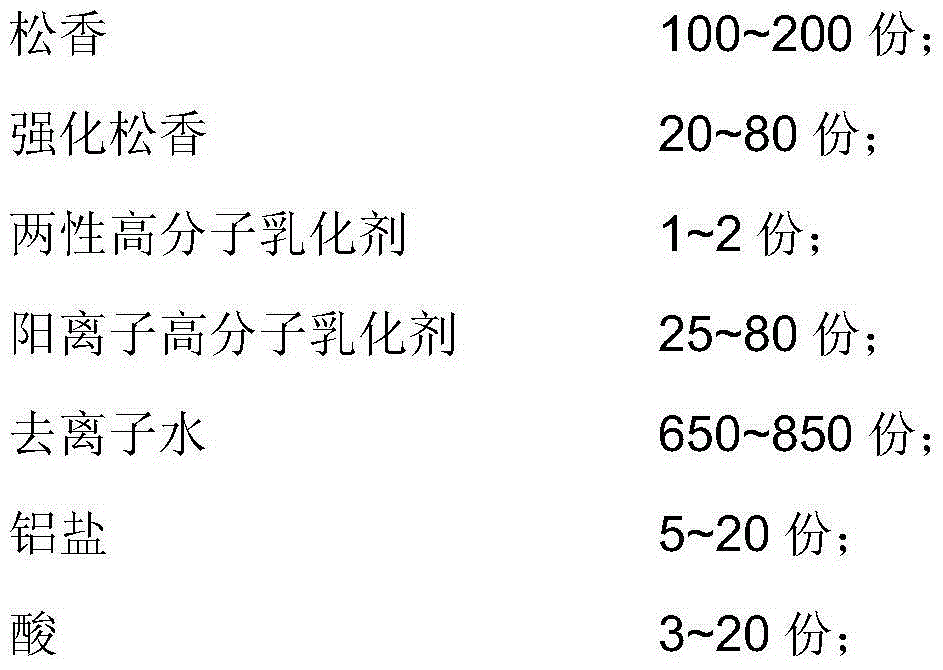

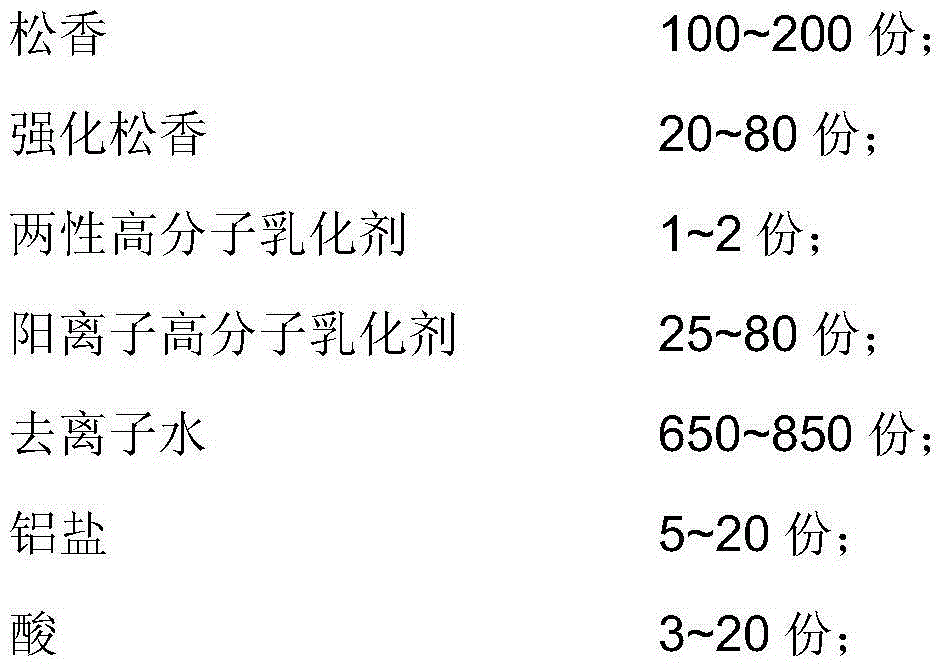

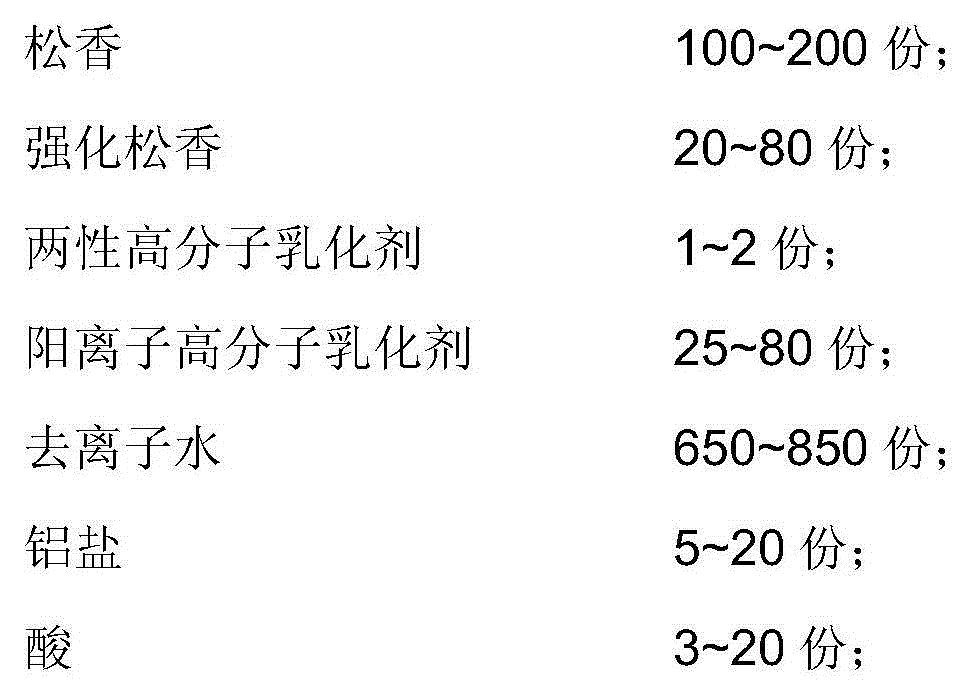

[0021] The invention provides a kind of preparation method of high-performance cationic rosin glue, it is characterized in that, comprises:

[0022] Step 1: Heat and melt the mixture of rosin and fortified rosin, keeping the temperature at about 150-190°C;

[0023] Step 2: Heat the amphoteric polymer emulsifier solution to above 96°C, and slowly add it dropwise into the mixed rosin melt under stirring conditions, and continue to emulsify for 10 minutes after dropping;

[0024] Step 3: Heat the cationic polymer emulsifier solution to above 96°C, slowly add it dropwise into the mixed rosin melt, and continue to emulsify for 30 minutes after the drop;

[0025] Step 4: Heat deionized water to above 96°C, add it slowly and then quickly to the material, and increase the stirring speed to above 1500 rpm, and reduce the stirring speed to below 100 rpm after the phase inversion of the system;

[0026] Step 5: Rapidly cool the emulsion to below 38°C through the cooling device, then add...

Embodiment 1

[0038] Heat and melt the mixture of 200g rosin and 100g fuma rosin, keeping the temperature at about 160°C; heat 25g of 20% amphoteric polymer emulsifier solution to 98°C, and slowly add it dropwise into the mixed rosin melt while stirring , continue to emulsify for 10 minutes after dropping; heat 300g of 40% cationic polymer emulsifier solution to 98°C, slowly add dropwise to the mixed rosin melt, and continue emulsifying for 30 minutes after dropping; heat 590g of deionized water to 98 ℃, first slowly and then quickly add to the material, and increase the stirring speed to 2000 rpm, and reduce the stirring speed to 100 rpm after the phase inversion of the system; quickly cool the emulsion to 35 °C through the cooling device, and then add 20% aluminum 500g of salt solution, stirred evenly, adjusted the pH value to 3.0 with acid, discharged, and cleaned the reaction device.

Embodiment 2

[0040] Heat and melt the mixture of 200g rosin and 100g maleic rosin, keeping the temperature at about 160°C; heat 25g of 20% amphoteric polymer emulsifier solution to 98°C, and slowly add it dropwise into the mixed rosin melt under stirring , continue to emulsify for 10 minutes after dropping; heat 250g of 40% cationic polymer emulsifier solution to 98°C, slowly add dropwise to the mixed rosin melt, and continue emulsifying for 30 minutes after dropping; heat 580g of deionized water to 98 ℃, first slowly and then quickly add to the material, and increase the stirring speed to 2000 rpm, and reduce the stirring speed to 100 rpm after the phase inversion of the system; quickly cool the emulsion to 35 °C through the cooling device, and then add 20% aluminum 500g of salt solution, stirred evenly, adjusted the pH value to 3.0 with acid, discharged, and cleaned the reaction device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com