System and method for simultaneously performing circulation utilization on sewage, sludge and domestic garbage

A technology for domestic waste and sludge, applied in the fields of sludge treatment, oxidation treatment of sludge, chemical instruments and methods, etc., can solve problems such as sludge disposal through landfills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

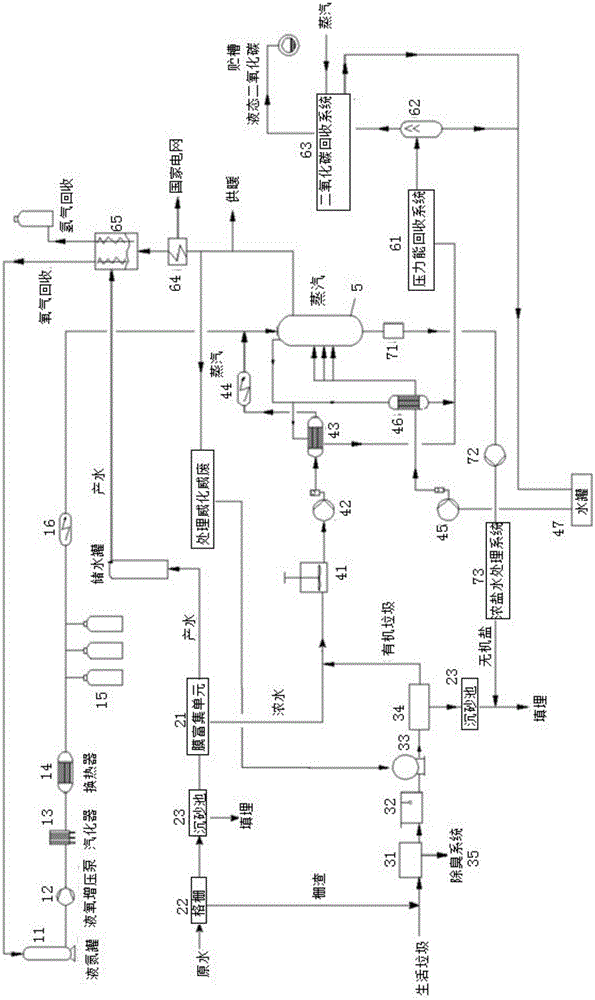

[0042] Such as figure 1 As shown, the system of the present invention includes an oxidant supply system, a membrane enrichment system, a garbage pretreatment system, a material input system, and a reactor 5, wherein:

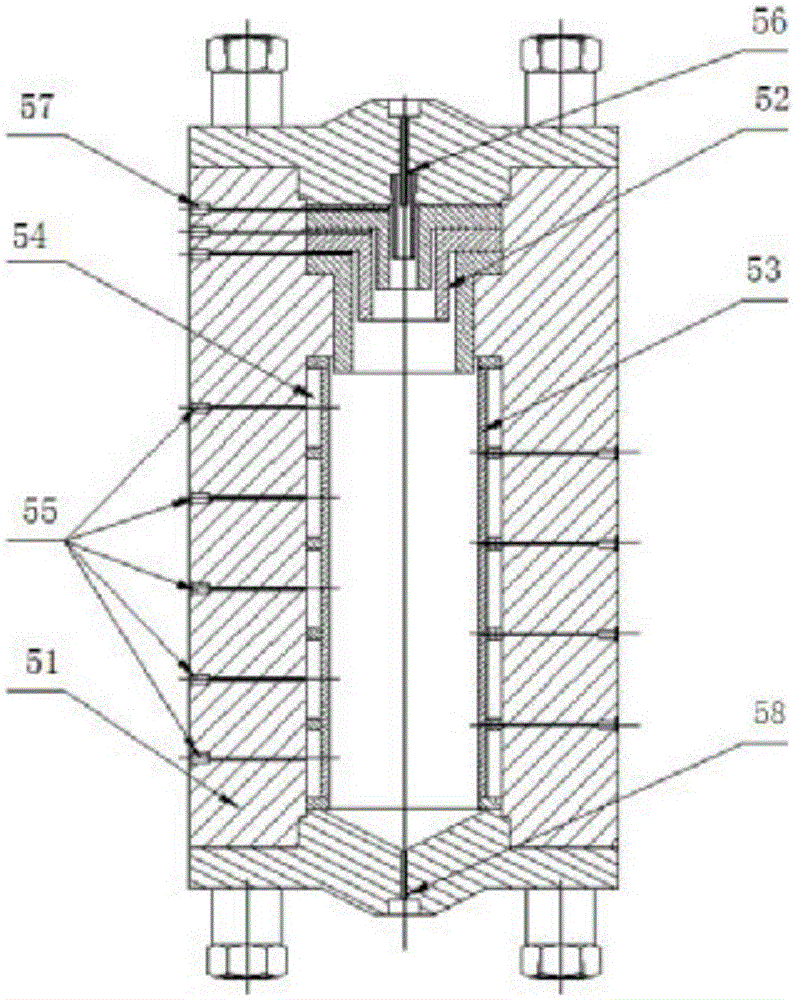

[0043] The oxidant supply system is used to supply oxidants such as oxygen or hydrogen peroxide with a temperature and pressure range of 300-400°C and 25-30Mpa high temperature and high pressure to the reactor, including an oxygen storage tank 11, a booster pump 12, a vaporizer 13, a first The heat exchanger 14 and the first preheater 16, the high-pressure buffer tank 15 is connected to the gas path between the first heat exchanger 14 and the first preheater 16, and the oxygen outlet of the first preheater 16 is connected to the reactor 5 The oxidant inlet 57.

[0044] The membrane enrichment system includes a pretreatment unit and a membrane enrichment unit 21, wherein the pretreatment unit includes a grid 22 and a grit chamber 23 connected in sequence to filt...

Embodiment 2

[0053] Outlets of the first heat exchanger 14 , the second heat exchanger 43 and the third heat exchanger 46 are sequentially connected to the pressure energy recovery system 61 , the gas-liquid separation system 62 and the carbon dioxide recovery system 63 , which is an extension of Embodiment 1. Among them, the pressure energy recovery system 61 recovers the gas pressure through a hydraulic turbine, and then uses the recovered pressure for power generation; in the gas-liquid separation system 62, the depressurized gas is dehydrated by a gas-liquid separator and an adsorber, and then passed through a water cooling system. The temperature of the device is lowered to 25°C, and the oxygen is separated by the rectification tower and sent to the oxidant supply system for reuse; the separated gas is sent to the carbon dioxide recovery system 63 to recover carbon dioxide; the water separated by the gas-liquid separator and the carbon dioxide recovery system 63 enters the water tank 47...

Embodiment 3

[0055] The steam output from the upper part of the reactor 5 is respectively used for power generation, heating, hazardous waste treatment and hydrogen production, which is an extension of Embodiment 1. Specifically, the cooling water from the generator unit 64 and the produced water output from the membrane enrichment unit 21 enter the electrolytic cell 65, the hydrogen obtained by electrolysis is recovered, and the oxygen is input into the oxidant supply system for reuse; steam is used to sterilize hazardous waste , the sterilized hazardous waste enters the grinder 33 of the garbage pretreatment system to be ground together with sludge and domestic garbage. Hazardous waste refers to hazardous chemicals and hazardous waste produced in industrial or medical processes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com