Processing technique of liquid carbon dioxide by decarbonizing and resolving synthetic ammonia

A liquid carbon dioxide, processing technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of high production costs, low product quality, large fluctuations in purity and impurity content, and reduce product Energy consumption and product cost, the effect of improving economic efficiency and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

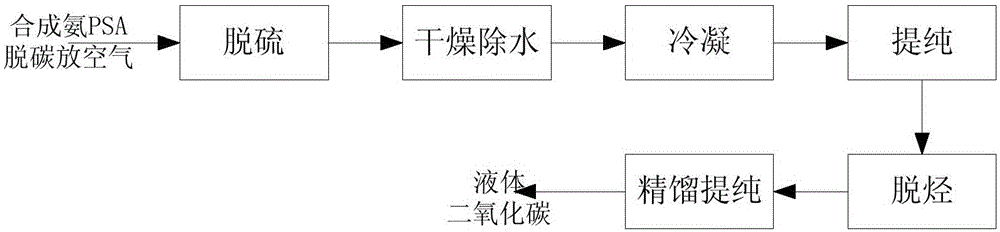

[0018] During specific implementation, combined with figure 1 Process flow chart, a process for decarburizing and analyzing liquid carbon dioxide from synthetic ammonia, including the following steps:

[0019] 1) Desulfurization: Synthetic ammonia PSA decarburization releases air, raw material gas enters CO after being pressurized and cooled by fan 2 The first stage and the second stage of the compressor, after two stages of compression, go to the desulfurization heater to recover heat, and then go to the crude desulfurization double tower to remove H in the raw material gas 2 S, and then return to the third and fourth stages of the compressor, after being heated to 60°C by the desulfurization heater, it enters the hydrolysis tower to hydrolyze COS, and after the desulfurization water cooler cools down to normal temperature, the desulfurization tower will hydrolyze the generated H 2 S removed.

[0020] Synthetic ammonia PSA decarburization releases the gas in the air with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com