Oxide and molecular sieve compound catalyst and preparation and application thereof

A composite catalyst and molecular sieve technology, which is applied in molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of ozone layer destruction, low selectivity, difficult to be removed, etc., and achieve good N2 selectivity and catalytic activity High, strong anti-HCs poisoning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of a low-temperature denitration catalyst composited with oxides and molecular sieves, the steps are as follows:

[0026] First, take 12.08g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 500mL of deionized water to prepare 0.1mol / L Cu(NO 3 ) 2 solution. Add H-SSZ-13 with a Si / Al ratio of 13.6 into the copper nitrate solution, stir in an oil bath at a constant temperature of 80°C for 2h, filter and wash the sample with deionized water, and bake it at 100°C for 12h.

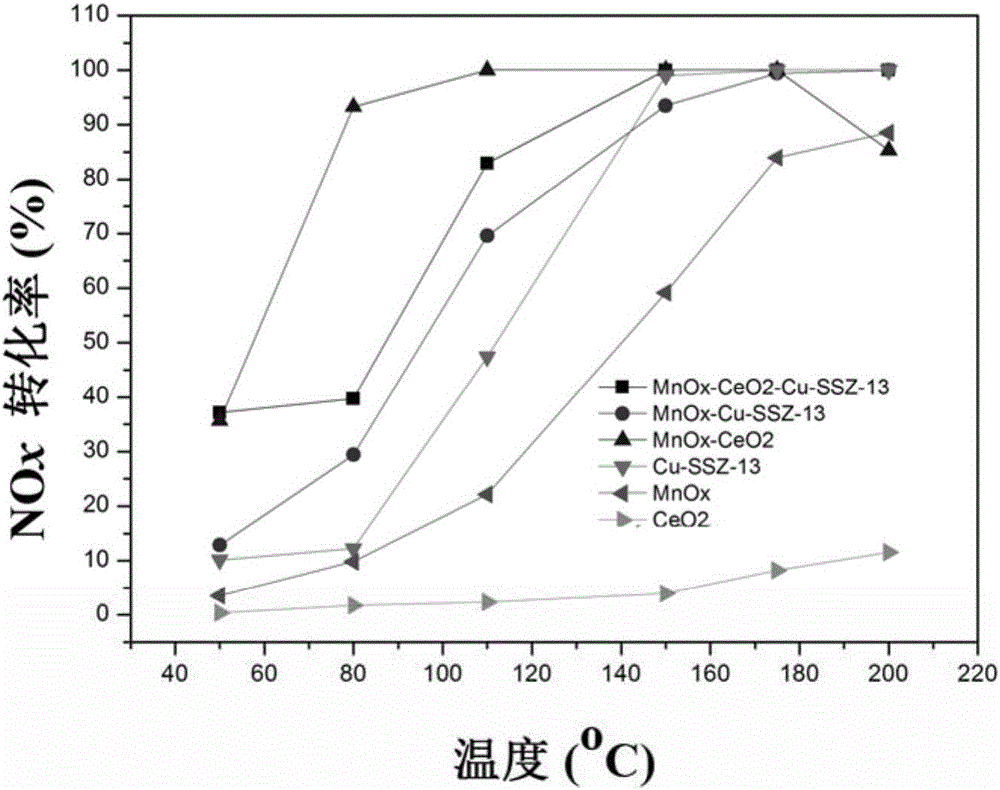

[0027] Preparation of Composite Catalyst Mn by Impregnation Method x -Cey / Cu-SSZ-13, take 1.34g of manganese nitrate and 0.45g of cerium nitrate, dissolve in a certain amount of deionized water, then add the prepared copper-based molecular sieve catalyst Cu-SSZ-13 into the mixed solution, magnetic Stir until it becomes a paste, dry the paste mixture at 100°C overnight, and then place it in a muffle furnace for calcination at 550°C for 4h. MnO in the catalyst x , CeO 2 , Cu-SSZ-13 p...

Embodiment 2

[0034] Example 2: Preparation of a low-temperature denitration catalyst Mn compounded with oxides and molecular sieves x -Ce y / Cu-SSZ-13, the basic steps are the same as in Example 1, except for MnO x , CeO 2 , The percentage of Cu-SSZ-13 was changed to 4%, 6%, 90%.

Embodiment 3

[0035] Example 3: Preparation of a low-temperature denitration catalyst Mn compounded with oxides and molecular sieves x -Ce y / Cu-SSZ-13, the basic steps are the same as in Example 1, except for MnO x , CeO 2 , The percentage of Cu-SSZ-13 was changed to 8%, 2%, 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com