A centrifugal microfluidic chip and a method for continuously synthesizing janus particles

A microfluidic chip and centrifugal technology, applied in the field of microfluidics, to achieve the effect of improving the synthesis yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

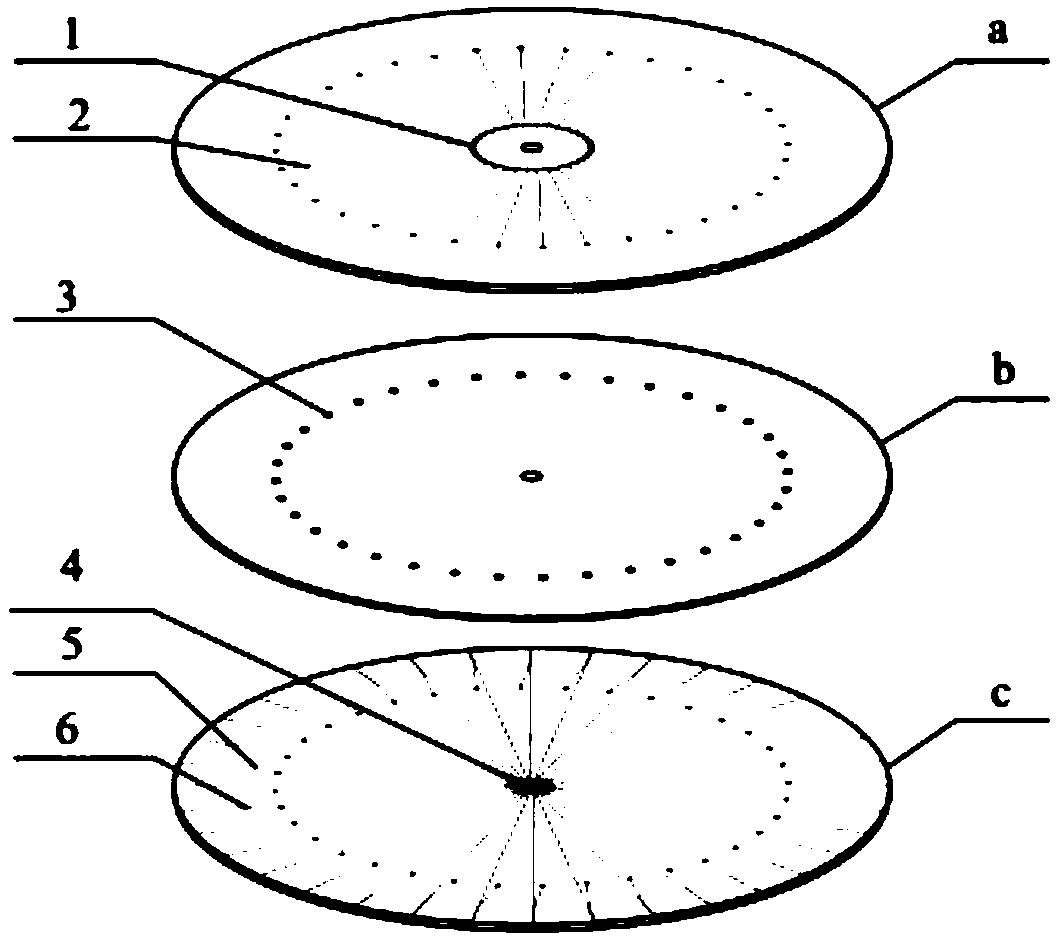

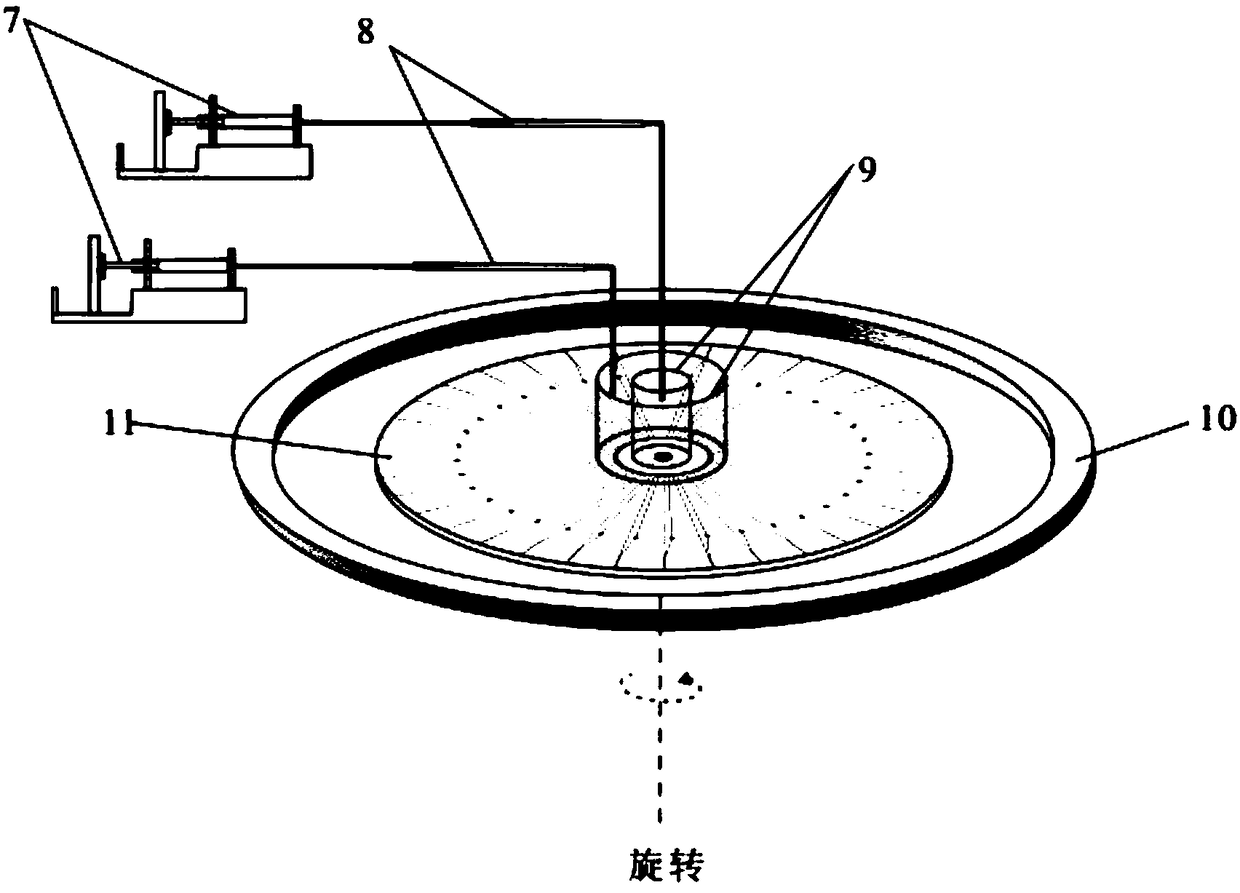

[0056] The centrifugal microfluidic chip of the present invention, such as figure 1 As shown, it is composed of an upper substrate a, an intermediate substrate b and a lower substrate c; the upper substrate, the intermediate substrate and the lower substrate are concentric circles and are equal in size;

[0057] For the upper substrate, an upper central circular hole is arranged at the center of the upper substrate; an annular liquid pool 1 is arranged on the upper substrate, and the annular liquid pool 1 is concentric with the upper substrate a, and the annular liquid pool 1 is concentric with the upper substrate a. The pool 1 penetrates the upper substrate a, and the outer side of the annular liquid pool 1 is provided with several upper dispersed circular channels, and several upper dispersed circular channels are evenly distributed on the upper substrate along the circumferential direction. The annular liquid pools are connected through a first-level straight channel 2, and...

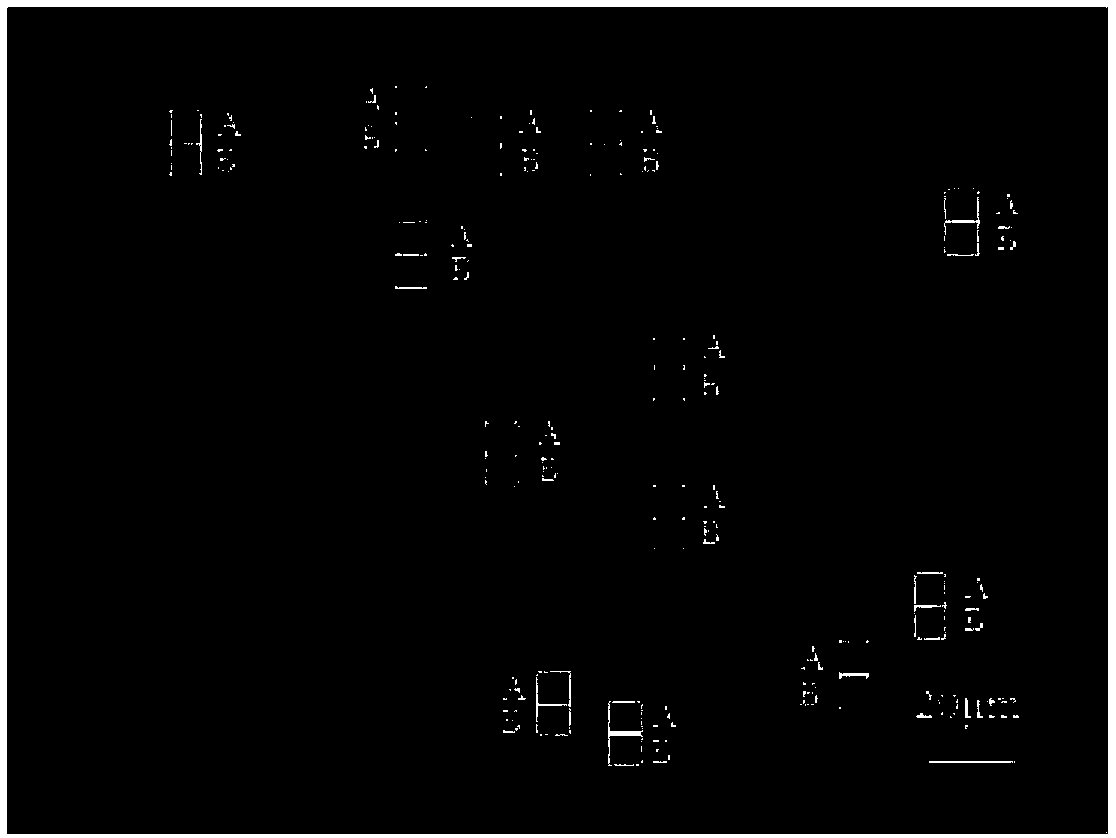

Embodiment 2

[0087] The structure and material of the centrifugal microfluidic chip used in this example are the same as in Example 1, but the size is different:

[0088] In this implementation, the diameter of the annular liquid pool is 14mm, and the diameter of the upper substrate is 70mm, then S:D=14:70; and the difference between the inner diameter and outer diameter of the upper annular liquid pool is 1mm;

[0089] In this implementation, the upper substrate is provided with 36 upper dispersed circular holes, and the diameter of the upper dispersed circular hole is 0.9 mm; the center distance between the upper dispersed circular channel and the upper substrate is 28.45 mm;

[0090] In this implementation, the width of the first-level straight channel=the width of the second-level straight channel=the width of the third-level straight channel, both of which are 200 μm;

[0091] In this implementation, the distance between the connecting point of the secondary straight channel and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com