Method for preparing double-microporous layers for improving performance of fuel batteries

A fuel cell and microporous layer technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of membrane damage and uneven surface morphology of the microporous layer, improve mass transfer performance, facilitate water management, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

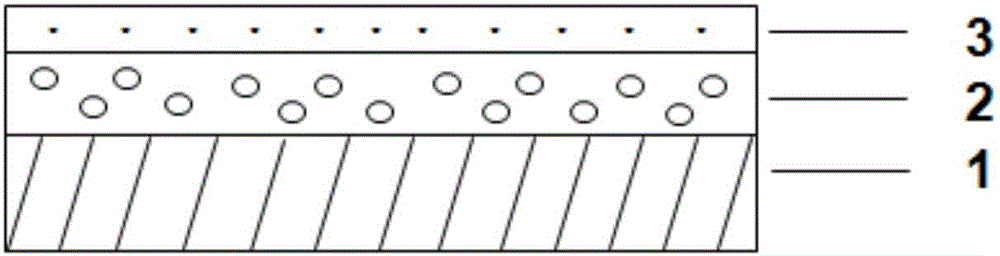

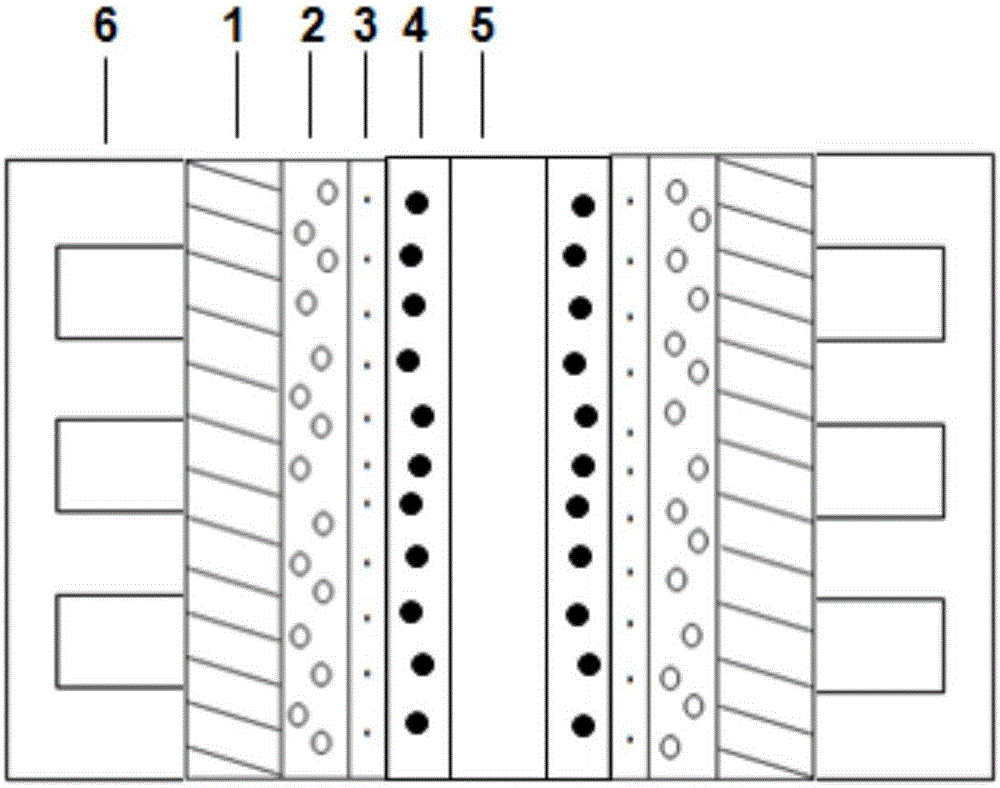

[0030] Such as figure 1 Shown, a kind of double-layer microporous layer preparation method that improves fuel cell performance comprises the steps:

[0031] S1. The highly conductive material, pore-forming agent, hydrophobic agent and dispersion liquid are prepared by stirring into the first slurry with uniform composition; the high-conductivity material is selected from carbon black; the pore-forming agent is selected from inorganic Pore-forming agent or organic pore-forming agent, described inorganic pore-forming agent is one or both in ammonium carbonate, ammonium oxalate, lithium carbonate; Described dispersion liquid is alcohols, selects ethanol, isopropanol, ethylene glycol One or two of them; the carbon paper or carbon cloth is impregnated with a 0.1%-5% PTFE water dispersion, with a thickness of 150 μm-300 μm and a porosity of more than 60%.

[0032] The preparation method of the first slurry is as follows: add a certain amount of carbon black into the dispersion medi...

Embodiment 1

[0040] This embodiment provides a method for preparing a microporous layer with high surface smoothness and good gas mass transfer performance, which includes the following steps:

[0041] 1) Weigh 3g of carbon black, 60ml of ammonium oxalate saturated aqueous solution, 10g of 20% PTFE diluent and pour it into a certain amount of isopropanol, stir evenly to make the first slurry with a viscosity between 250cp-350cp;

[0042] 2) Apply the above slurry on the hydrophobically treated carbon paper by screen printing to form a first coating layer with a coating thickness of 20 μm;

[0043] 3) Weigh 3g of carbon black, 10g of 20% PTFE dispersion and pour into a certain amount of isopropanol, mix evenly to make the second slurry with viscosity between 30cp-60cp;

[0044] 4) Apply the above-mentioned slurry to the surface of the first coating layer of screen printing by spraying to form a second spraying layer with a spraying thickness of 15 μm;

[0045] 5) Put the above slurry-coate...

Embodiment 2

[0052] The preparation method of the diffusion layer in Example 2 is the same as in Example 1, except that the thickness of the first microporous layer in Example 2 is 25 μm, and the thickness of the second microporous layer is 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com