Liquid discharge plasma emission spectroscopy device and metallic element determining method

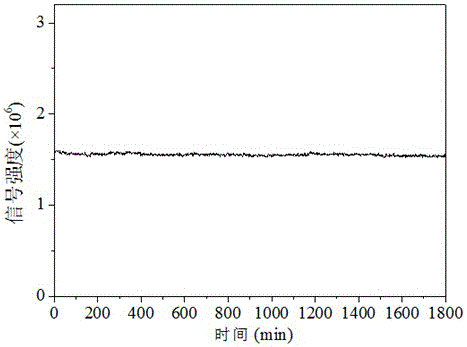

A discharge plasma and emission spectroscopy technology, applied in the field of atomic emission spectroscopy analysis and testing in analytical chemistry, can solve the problems of high cost of dual-channel peristaltic pumps, large volume of samples to be tested, and inability to continuously inject samples, and achieve excellent discharge stability. , The effect of improving the photoexcitation efficiency and reducing the power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

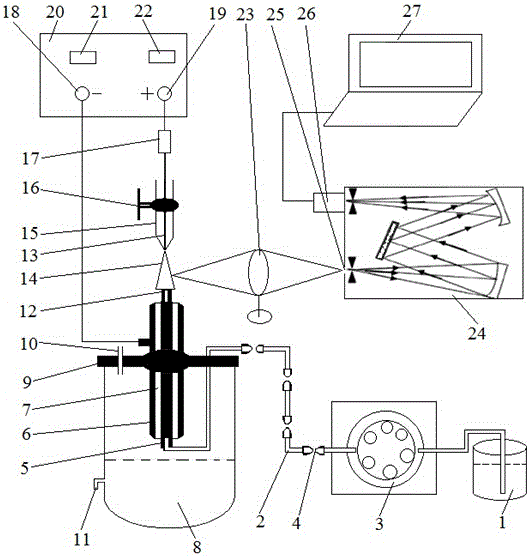

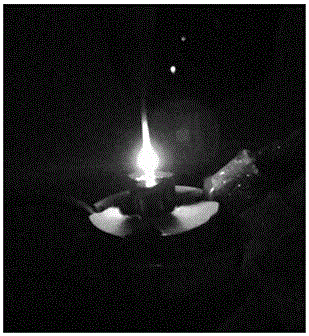

[0043] The position between the platinum electrode 13 and the capillary top part 12 is adjusted by the translation stage 16, so that the platinum electrode 13 and the capillary top part 12 are on the same axis, and the distance between the platinum electrode 13 and the capillary top part 12 is 2mm; The length is 3mm; HNO with pH=1 3 Put the solution into the sample pool 1, turn on the peristaltic pump 3, make the solution to be tested flow into the capillary 5 at a flow rate of 4.5 mL / min, and overflow from the top part 12 of the capillary to form a fountain-like liquid surface, adjust the translation platform 16 to make the fountain-like liquid The surface is just in contact with the lower end surface of the platinum electrode 13; the DC stabilized power supply 20 is turned on, at this time, the fountain-like liquid surface becomes the cathode of the liquid discharge, and the platinum electrode 13 becomes the anode, and a voltage of 650V and a current of 70mA are applied betwe...

Embodiment 2

[0052] The position between the platinum electrode 13 and the capillary top part 12 is adjusted by the translation stage 16, so that the platinum electrode 13 and the capillary top part 12 are coaxial, and the distance between the platinum electrode 13 and the capillary top part 12 is 1 mm; the capillary top part 12 The length of the test solution is 2mm; put the solution to be tested into the sample pool 1, turn on the peristaltic pump 3, make the solution to be tested flow into the capillary 5 at a flow rate of 1mL / min, and overflow from the top part 12 of the capillary to form a fountain-like liquid level, adjust the translation Platform 16 makes this fountain-like liquid surface just contact with the lower end platinum wire surface of conical platinum electrode 13; Apply a voltage of 640 V and a current of 95 mA between the electrodes, and the liquid overflowing from the top part of the capillary 12 will be vaporized and broken down to generate glow and form the excitation ...

Embodiment 3

[0054] The position between the platinum electrode 13 and the capillary top portion 12 is adjusted by the translation stage 16, so that the platinum electrode 13 and the capillary top portion 12 are coaxial, and the distance between the platinum electrode 13 and the capillary 12 is 3mm; the length of the capillary top portion 12 4mm; put the solution to be tested into the sample pool 1, turn on the peristaltic pump 3, make the solution to be tested flow into the capillary 5 at a flow rate of 6 mL / min, and overflow from the top part 12 of the capillary to form a fountain-like liquid level, adjust the translation stage 16 Make the fountain-like liquid surface just in contact with the lower end surface of the platinum electrode 13; turn on the DC stabilized power supply 20, at this time, the fountain-like liquid surface becomes the liquid discharge cathode, and the platinum electrode 13 becomes the discharge anode, and a voltage of 700 V is applied between the two electrodes , 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com