SERS substrate based on metal dot matrix, preparation method of SERS substrate and method for conducting Raman detection through SERS substrate

A metal lattice and metal dot technology, applied in the field of analysis and detection, can solve problems such as hindering the pace of market application of SERS technology, restricting the actual promotion of SERS technology, and limited Raman signal gain effect, saving detection time and improving detection. Sensitivity, good effect of enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

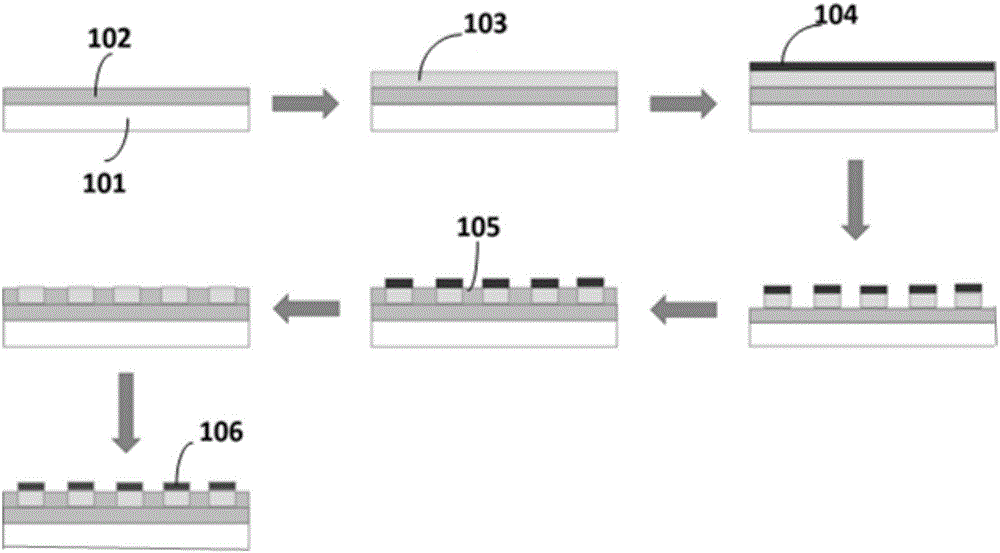

[0047] A method for preparing a SERS substrate based on a gold lattice, comprising the following steps:

[0048] (1) Take a piece of glass, first wash it with deionized water, then dry it with nitrogen, put it in acetone for 10 minutes, then take it out and clean it with deionized water, and finally dry it with nitrogen for use; A titanium metal layer with a thickness of 10 nanometers was vapor-deposited on the glass sheet by the method, and then a gold layer with a thickness of 100 nanometers was vapor-deposited on the titanium metal layer;

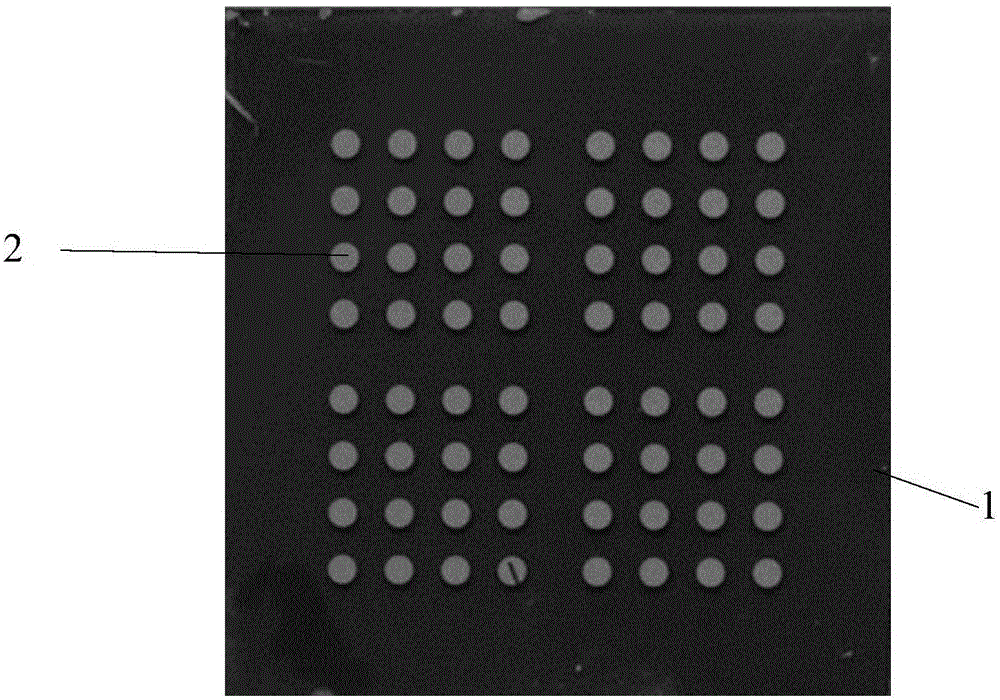

[0049] (2) Design a series of 4×4 dot matrix masks with CAD, the diameter of each gold dot is 1 mm, spin-coat photoresist on the gold layer, and cover the designed mask on the gold layer , placed in a photolithography machine, using aqua regia configured with a volume ratio of 1:3 to corrode the gold layer for 300 seconds, that is, a series of gold dots are formed on the titanium metal layer, and a gold lattice is obtained; figure 1 As ...

Embodiment 2

[0052] A method for preparing a SERS substrate based on a gold lattice, comprising the following steps:

[0053] (1) Take a piece of glass, first wash it with deionized water, then dry it with nitrogen, put it in acetone for 10 minutes, then take it out and clean it with deionized water, and finally dry it with nitrogen for use; A titanium metal layer with a thickness of 100 nanometers was vapor-deposited on the glass sheet by the method, and then a gold layer with a thickness of 500 nanometers was vapor-deposited on the titanium metal layer;

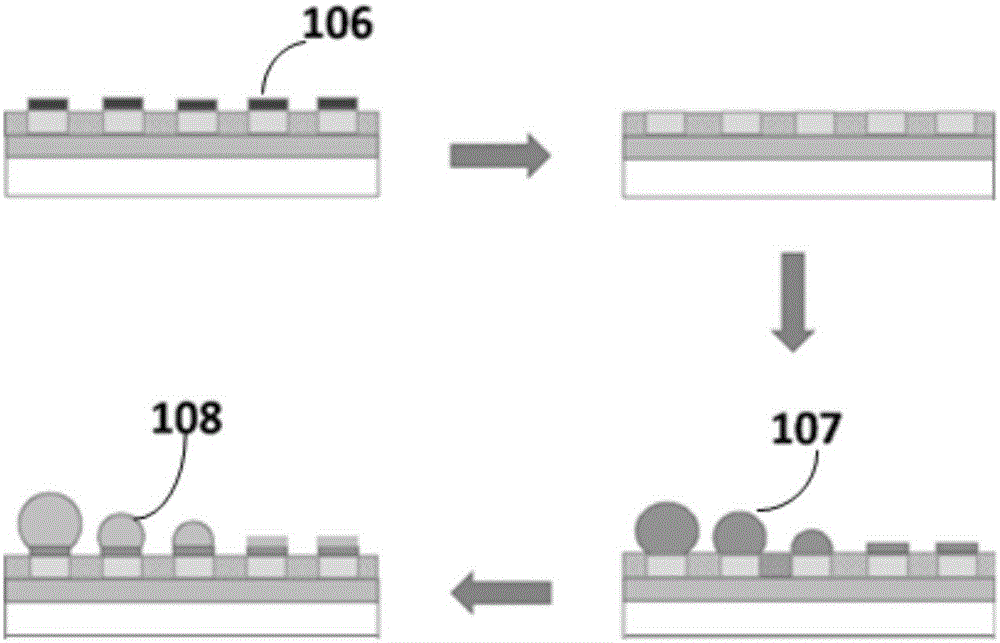

[0054] (2) Design a series of 4×4 dot matrix masks with CAD, the diameter of each gold dot is 0.6 mm, spin-coat photoresist on the gold layer, and cover the designed mask on the gold layer , placed in a photolithography machine, using aqua regia configured with a volume ratio of 1:3 to corrode the gold layer for 600 seconds, that is, a series of gold dots are formed on the titanium metal layer to obtain a gold lattice;

[0055] (3) Hyd...

Embodiment 3

[0059] A method for preparing a SERS substrate based on silver dot matrix, comprising the following steps:

[0060] (1) Take a piece of glass, first wash it with deionized water, then dry it with nitrogen, put it in acetone for 10 minutes, then take it out and clean it with deionized water, and finally dry it with nitrogen for use; A titanium metal layer with a thickness of 10 nanometers was vapor-deposited on the glass sheet by the method, and then a silver layer with a thickness of 100 nanometers was vapor-deposited on the titanium metal layer;

[0061] (2) Design a series of 4×4 dot matrix masks with CAD, the diameter of each silver dot is 0.2 mm, spin-coat photoresist on the gold layer, and cover the designed mask on the silver layer , placed in a photolithography machine, using aqua regia configured with a volume ratio of 1:3 to corrode the silver layer for 200 seconds, that is, a series of silver dots are formed on the titanium metal layer to obtain a silver lattice;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com