Sensing array capable of implementing high-accuracy synchronous measurement of three-dimensional deformation and three-dimensional pressure

A high-precision synchronous sensor array technology, applied in the direction of electric/magnetic solid deformation measurement, force measurement, and measurement devices, can solve the problems of low measurement accuracy, insufficient compact structure, and low spatial resolution, and achieve high measurement sensitivity , compact structure, and the effect of improving spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The sensor array (the overall size of the sensor array structure is consistent with the seat interface) that can realize three-dimensional deformation and three-dimensional pressure simultaneous measurement with high precision will be described as an example below.

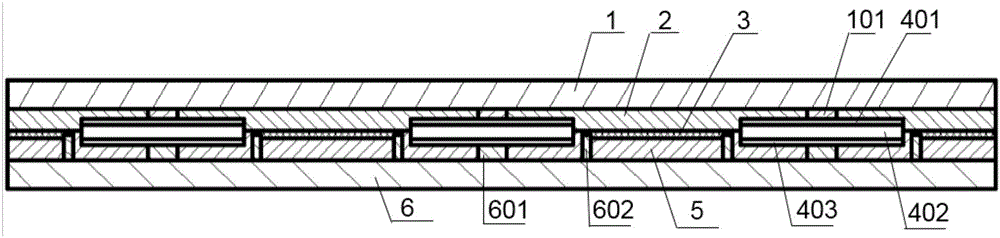

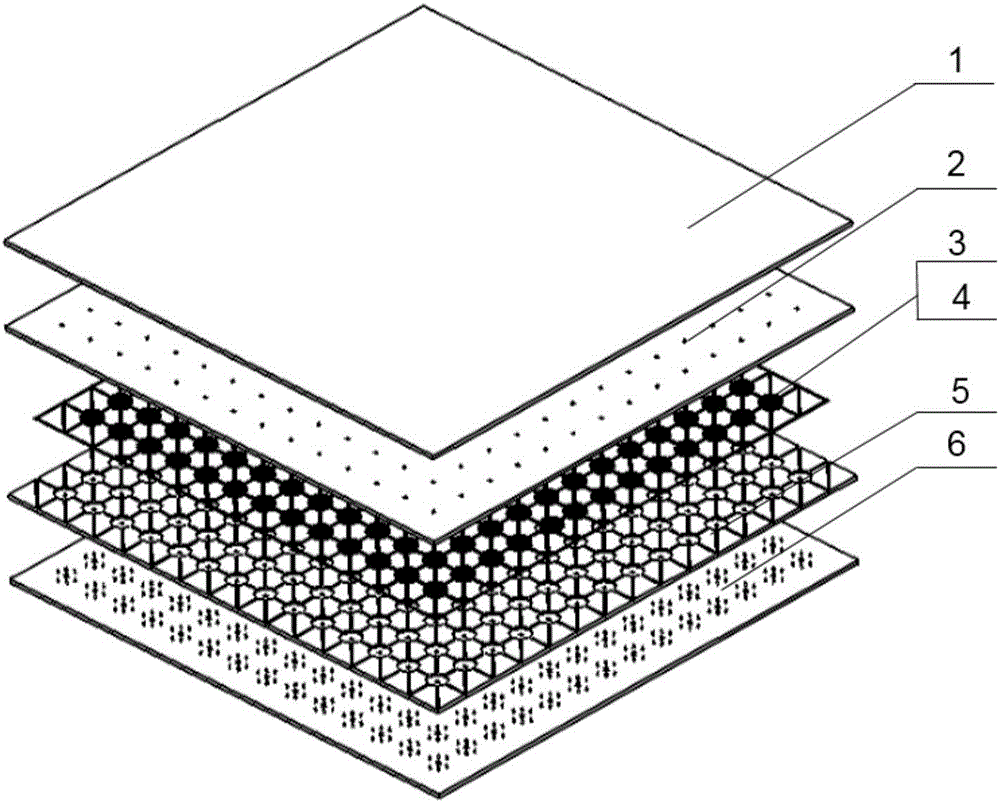

[0040] It includes a lower flexible circuit board 6, a lower elastic polymer substrate 5 with grooves, an array of capacitor units 4 and elastic piezoresistive units 3 arranged in the grooves, an upper elastic polymer substrate 2, and an upper flexible circuit board 1; The unit 4 and the elastic piezoresistive unit 3 are integrated into a mesh sensing array structure, wherein each capacitive unit 4 is adjacent to six elastic piezoresistive units 3 .

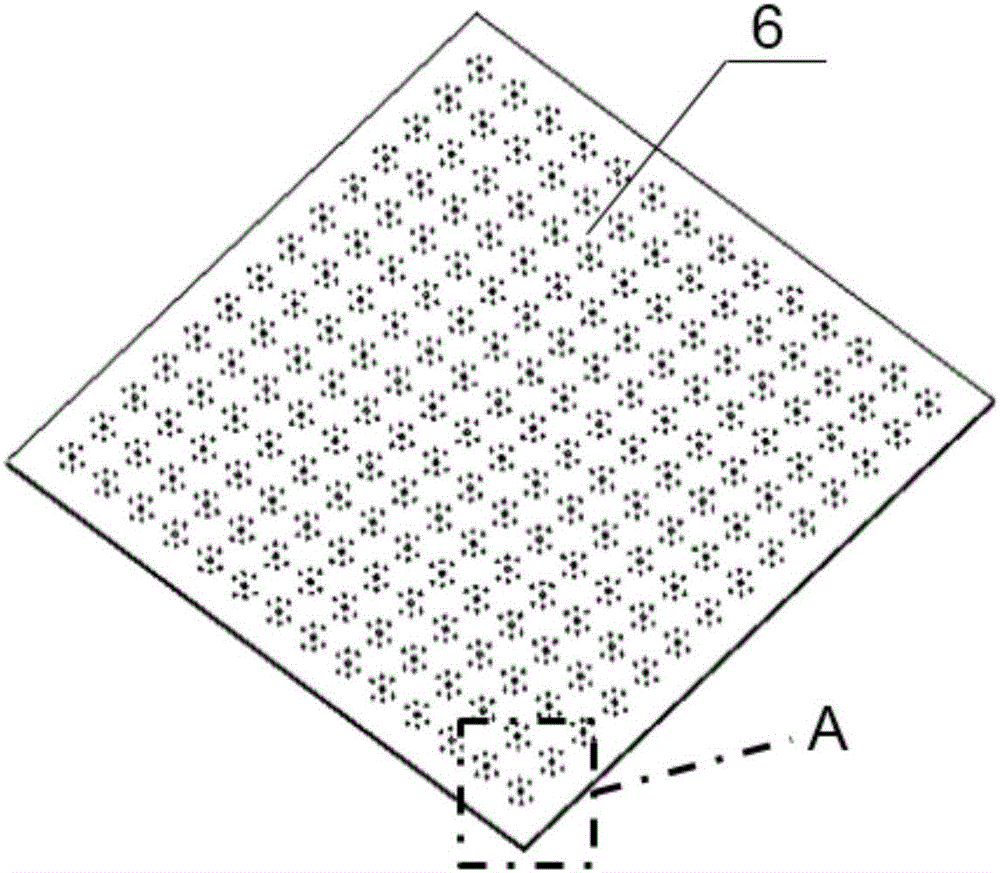

[0041] The central contact electrodes 601 and peripheral contact electrodes 602 on the lower flexible circuit board 6 according to the present invention are in the shape of convex cylinders, and each central contact electrode 601 and six adjacent peripheral con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com