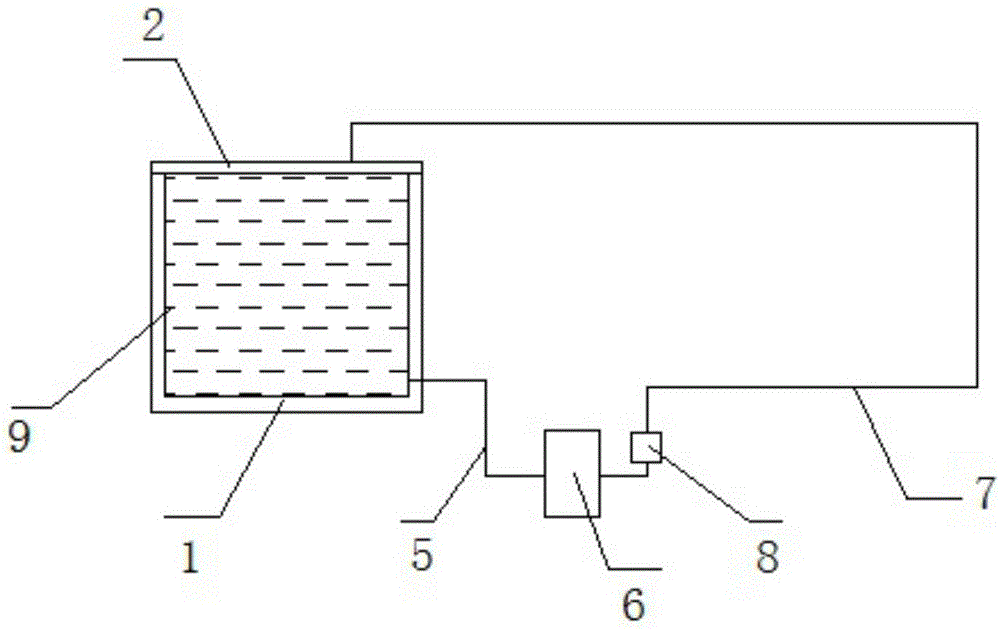

Water storage mechanism for wet-type grassed swale system

A grass planting ditch, wet technology, applied in the field of water storage mechanism for wet grass planting ditch system, can solve problems such as easy to be polluted, achieve simple operation, good ecology and landscape, and solve the effect of urban non-point source pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the above-mentioned anti-seepage layer is: in parts by weight, 75 parts of polyvinyl chloride, 65 parts of polyurethane resin, 15 parts of calcium carbonate, 23 parts of chlorinated paraffin, 22 parts of triethylamine, 8 parts of sodium tripolyphosphate, Add 32 parts of sodium fluorosilicate, 22 parts of stearic acid, 6 parts of hollow ceramic microspheres, 11 parts of vermiculite, 6 parts of mica powder, 24 parts of carboxymethyl cellulose, 12 parts of hydroxyl silicone oil, and 32 parts of water into the compression molding machine Press it into flakes.

[0036] The sheet-shaped anti-seepage layer is fixed on the inner wall of the reservoir by an adhesive, and the adhesive consists of 18 parts by weight of epoxy resin, 11 parts of silica gel, 7 parts of n-butanol, and 7.5 parts of polyester polyol. , 11 parts of boron fiber, 4 parts of methacrylic acid and 6 parts of vinyl acetate are mixed and prepared.

Embodiment 2

[0038] The preparation method of the above-mentioned anti-seepage layer is as follows: in parts by weight, 70 parts of polyvinyl chloride, 60 parts of polyurethane resin, 10 parts of calcium carbonate, 20 parts of chlorinated paraffin, 18 parts of triethylamine, 5 parts of sodium tripolyphosphate, Add 30 parts of sodium fluorosilicate, 20 parts of stearic acid, 5 parts of hollow ceramic microspheres, 10 parts of vermiculite, 3 parts of mica powder, 22 parts of carboxymethyl cellulose, 10 parts of hydroxyl silicone oil, and 30 parts of water into the compression molding machine Press it into flakes.

[0039] The sheet-shaped anti-seepage layer is fixed on the inner wall of the reservoir by an adhesive, and the adhesive consists of 15 parts by weight of epoxy resin, 10 parts of silica gel, 5 parts of n-butanol, and 7 parts of polyester polyol. , 10 parts of boron fiber, 2 parts of methacrylic acid and 3 parts of vinyl acetate are mixed and prepared.

Embodiment 3

[0041] The preparation method of the above-mentioned anti-seepage layer is as follows: in parts by weight, 80 parts of polyvinyl chloride, 70 parts of polyurethane resin, 20 parts of calcium carbonate, 25 parts of chlorinated paraffin, 26 parts of triethylamine, 10 parts of sodium tripolyphosphate, Add 35 parts of sodium fluorosilicate, 23 parts of stearic acid, 8 parts of hollow ceramic microspheres, 12 parts of vermiculite, 9 parts of mica powder, 28 parts of carboxymethyl cellulose, 15 parts of hydroxyl silicone oil, and 35 parts of water into the compression molding machine Press it into flakes.

[0042] The sheet-shaped anti-seepage layer is fixed on the inner wall of the reservoir by an adhesive, and the adhesive consists of 20 parts by weight of epoxy resin, 12 parts of silica gel, 10 parts of n-butanol, and 8 parts of polyester polyol. , 12 parts of boron fiber, 5 parts of methacrylic acid and 8 parts of vinyl acetate are mixed and prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com