High-temperature-resistant composite coating and preparation method thereof

A composite coating, high temperature resistant technology, applied in the field of composite electrodeposition, to achieve the effect of enhancing the performance of composite coating, reducing internal defects and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

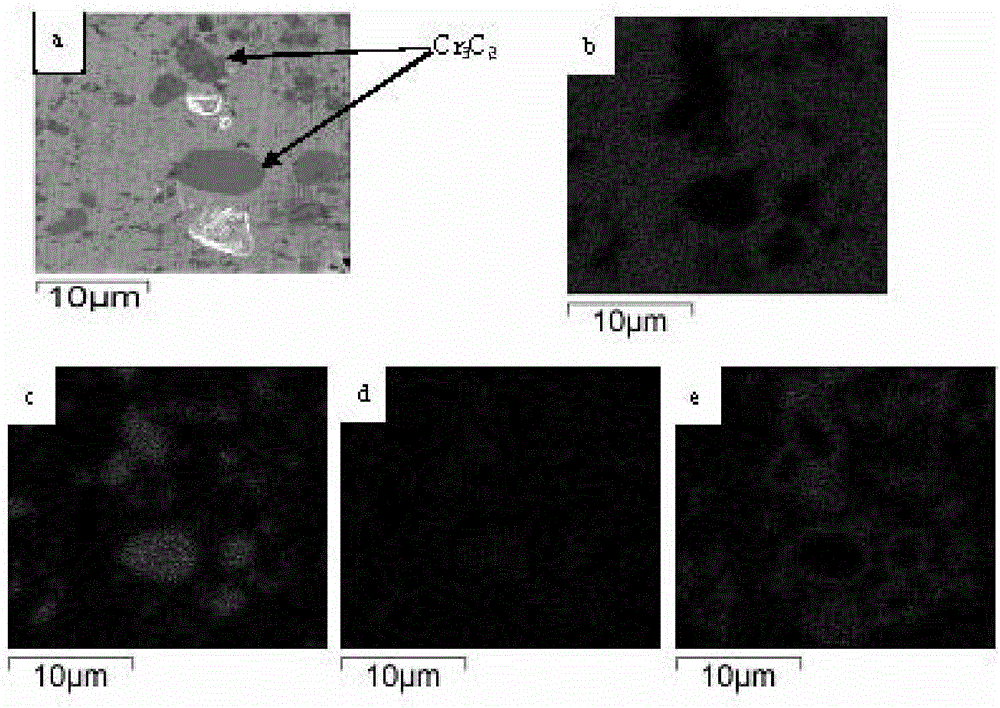

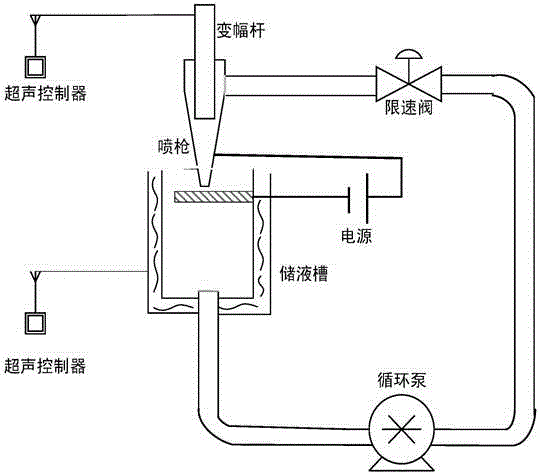

[0023] After the surface of 45 steel workpiece is pretreated, the surface is coated with Co-Cr by jet electrodeposition method. 3 C 2 Composite coating. Its plating method is:

[0024] 1) Configure the composite plating solution, which consists of: CoSO 4 ·7H 2 O 430g / L, NaCl 25g / L, H 3 BO 3 35g / L, CTAB0.2g / L, pH=3. The operating process is: current density 37A / dm 2 , the temperature is 40°C, the flow rate of the plating solution is 2.2L / min, and the relative moving speed of the anode and cathode is 3.0mm / s;

[0025] 2) Conduct electro-cleaning and activation treatment on the surface of 45 steel workpieces, and use nickel primer as the transition layer;

[0026] 3) The deposition time is 30 minutes.

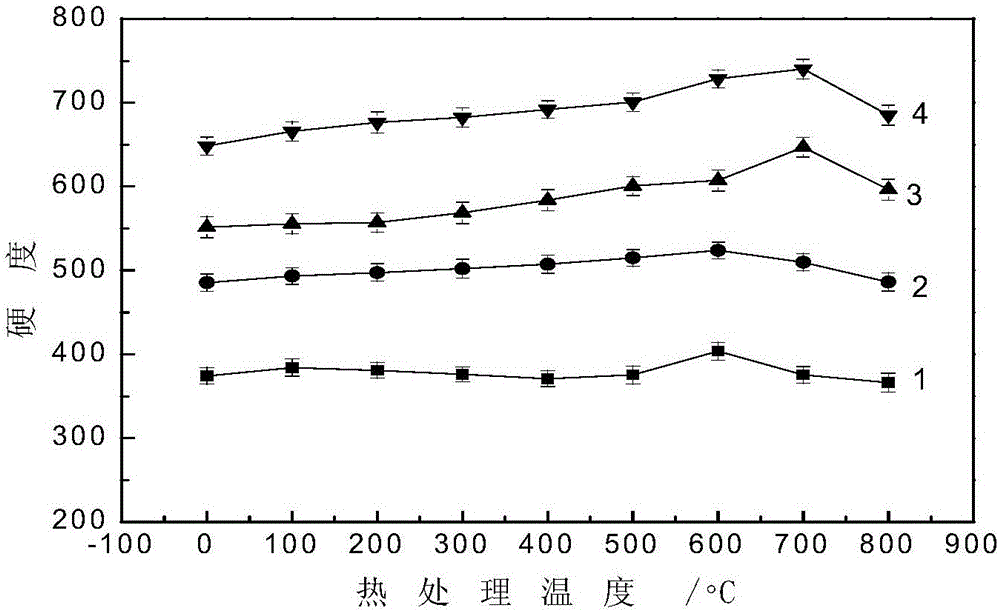

[0027] The obtained coating is a pure cobalt coating, the hardness of the coating is 374HV, the friction coefficient of the coating is 0.786, and the wear volume is 5.888×10 -3 mm 3 .

Embodiment 2

[0029] 1) Configure the composite plating solution, which consists of: CoSO 4 ·7H 2 O 430g / L, NaCl 20g / L, H 3 BO 3 35g / L, CTAB0.1g / L, nickel-containing (nickel mass content is nickel-containing Cr 3 C 2 30%-35% of the particles, the following examples are the same) Cr 3 C 2 Granules 350g / L, pH=4. The operating process is: current density 35A / dm 2 , the temperature is 40°C, the flow rate of the plating solution is 2.2L / min, and the relative moving speed of the anode and cathode is 3mm / s;

[0030] 2) Conduct electro-cleaning and activation treatment on the surface of 45 steel workpieces, and use nickel primer as the transition layer;

[0031] 3) The deposition time is 30 minutes.

[0032] The resulting composite coating, Cr 3 C 2 The mass fraction of particles is 9.2%, the hardness of the coating is 485.4HV, the friction coefficient of the coating is 0.538, and the wear volume is 2.052×10 -3 mm 3 .

Embodiment 3

[0034] 4) Configure the composite plating solution, which consists of: CoSO 4 ·7H 2 O 450g / L, NaCl 20g / L, H 3 BO 3 30g / L, CTAB0.3g / L, nickel-containing Cr 3 C 2 Granules 500g / L, pH=3. The operating process is: current density 40A / dm 2 , the temperature is 40°C, the flow rate of the plating solution is 2.3L / min, and the relative moving speed of the anode and cathode is 3mm / s;

[0035] 5) Conduct electro-cleaning and activation treatment on the surface of 45 steel workpieces, and use nickel primer as the transition layer;

[0036] 6) The deposition time is 30 minutes.

[0037] The resulting composite coating, Cr 3 C 2 The mass fraction of particles is 15.4%, the hardness of the coating is 552HV, the friction coefficient of the coating is 0.445, and the wear volume is 1.453×10 -3 mm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com