Method for preparing high-hardness high-strength-and-toughness iron-based wear resistant material through secondary alloying

A wear-resistant material, high-strength and toughness technology, applied in the field of powder metallurgy, can solve the problems of low hardness of the cast-inlaid anti-wear white cast iron block and high price of the inlaid-cast cemented carbide block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

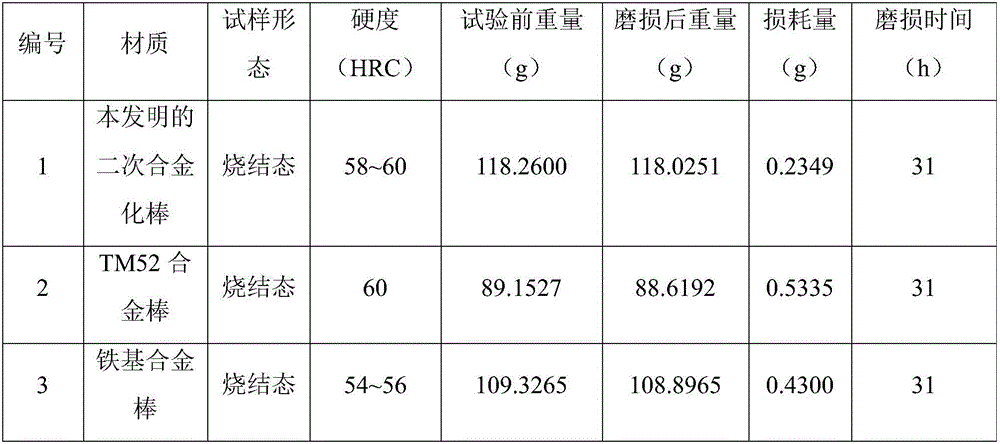

Examples

Embodiment

[0035] The pre-alloyed powder prepared by the present invention accounts for 90% to 93% of the total mass of the alloy, and the powder required for the second alloying accounts for 10% to 7% of the total mass of the alloy, totaling 100%; wherein the first alloying The mass percent content of the obtained pre-alloyed powder components is: Cr 18%-23%, Mo 0.8%-1.8%, Ni 0.6%-1.5%, Ti 0.3%-0.8%, Si 0.4%-1.0%, V 0.6%- 1.2%, C 2.4% to 2.9%, Fe is the balance. The mass percentage of each component in the powder added in the second sintering alloying is: Cu 12%-24%, Ni 12%-20%, Mo 9%-15%, Mn 6%-12%, TiC 15% ~25%, Fe is the balance; TiC particle size is less than 0.5μm, Mn is added as MnFe master alloy powder.

[0036] The implementation process of the first alloying to produce pre-alloyed powder is to calculate the content of each component according to the above mass percentage, then weigh it, add it to an intermediate frequency induction furnace for melting, and after the melting is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com