Method for producing aluminium alloy composite tube, bar and wire rod

A technology for composite pipes and aluminum alloys, which is applied in the field of rods and wires to produce aluminum alloy composite pipes, and can solve problems such as low production efficiency, low yield, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

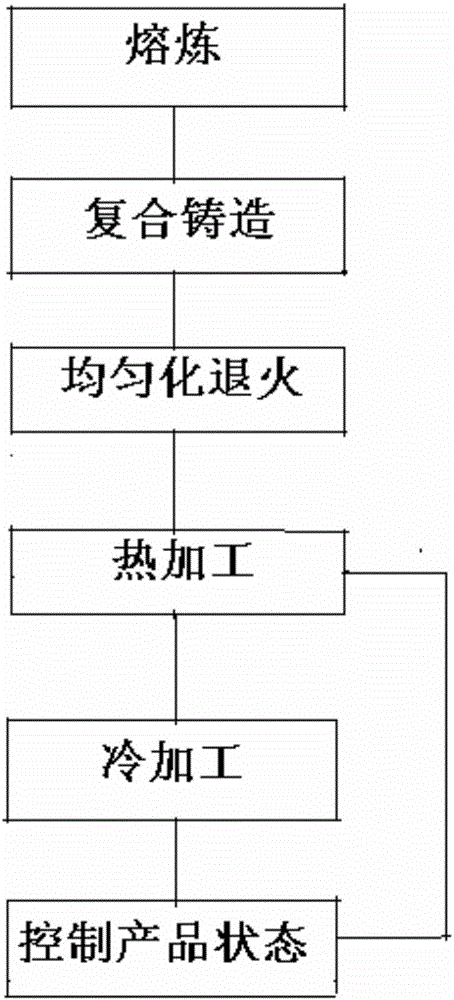

Method used

Image

Examples

Embodiment 1

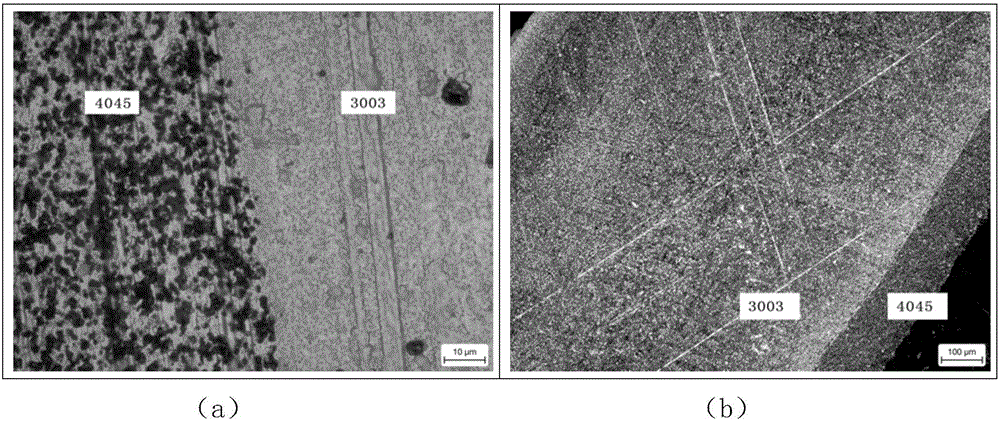

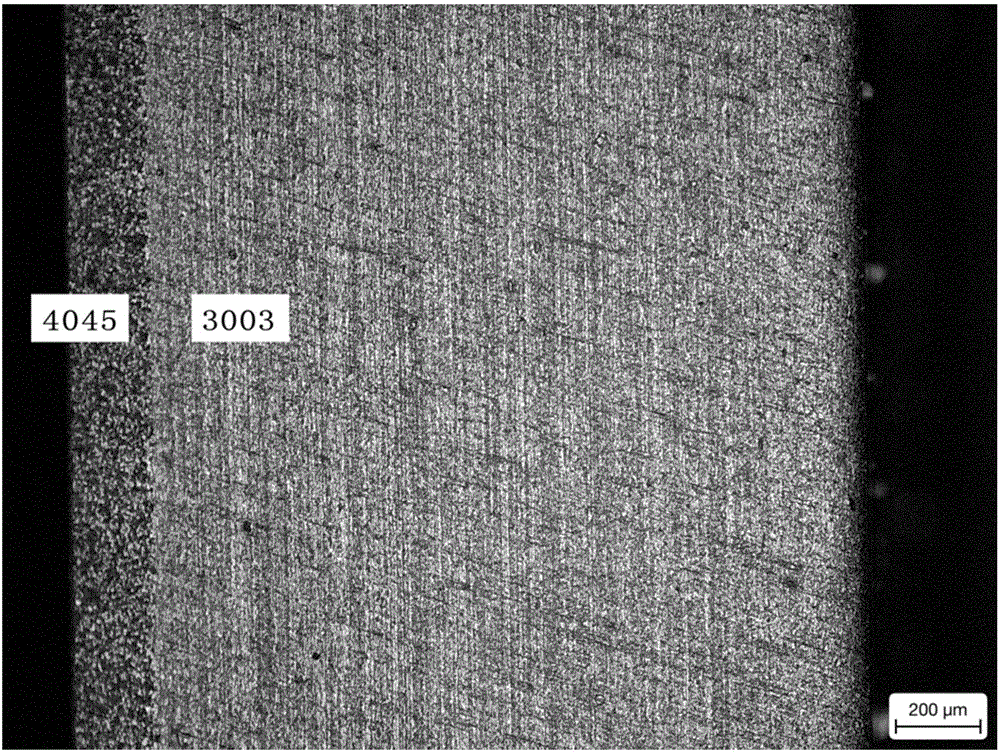

[0024] The production of aluminum alloy composite oval pipes with Al-1.3Mn-0.1Cu in O state as the core material and Al-20Si as the skin material,

[0025] Table 1

[0026]

[0027] The production steps are as follows:

[0028]Melting, as shown in Table 1, adding 0.1% Cu, 1.3% Mn and 98.6% Al into the core material melting furnace for smelting, the core material melting temperature is controlled at 20°C higher than the core material melting point. The core aluminum alloy melt is refined and filtered in the furnace; as shown in Table 1, 20% Si and 80% Al by mass percentage are added to the skin material melting furnace for smelting, and the skin material melting temperature is controlled at 50°C higher than the melting point of the skin material, then add 0.1% of P and 0.7% of Cr to the melt in the aluminum alloy of the skin, carry out modification treatment, and refine and filter outside the furnace, the core material and skin Material smelting time is not more than 20 ho...

Embodiment 2

[0032] The production of aluminum alloy composite round pipes with Al-1.6Mn as the core material and Al-30Si-1.0Mn as the skin material in the H state,

[0033] table 3

[0034]

[0035] The production steps are as follows:

[0036] (1) Melting, as shown in Table 3, the mass percentage is 1.6% Mn and 98.4% Al is added in the core material smelting furnace for smelting, the core material melting temperature is controlled at 60 ℃ higher than the core material melting point, the core material The aluminum alloy melt is refined and filtered in the furnace; as shown in Table 3, 30% Si, 1.0% Mn and 69% Al are added to the leather melting furnace for smelting, and the leather smelting The temperature is controlled at 150°C higher than the melting point of the leather material, and then 0.1% of P and 0.7% of Cr are added to the melt in the aluminum alloy of the skin to carry out modification treatment, and refined and filtered outside the furnace. The smelting time of wood and le...

Embodiment 3

[0040] Al-1.0Mn-0.1Si-0.1Cu in T5 state is used as the core material, and Al-15Si-3.5Cu-0.85Fe is used as the skin material for the production of aluminum alloy composite rods.

[0041] table 5

[0042]

[0043] The production steps are as follows: (1) smelting, as shown in Table 5, adding 0.1% Si, 0.1% Cu, 1.0% Mn and 98.8% Al into the core material smelting furnace for smelting, the core material The smelting temperature is controlled at 40°C higher than the melting point of the core material, and the core material aluminum alloy melt is refined and filtered in the furnace; as shown in Table 5, the mass percentages are 15% Si, 0.85% Fe, 3.5% Cu and 80.65% Al are added to the leather melting furnace for smelting. The melting temperature of the leather is controlled at 100°C higher than the melting point of the leather, and then 0.2% of P and 0.2% Cr is modified, refined and filtered outside the furnace, and the smelting time of core material and skin material is not more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com