Low-temperature solidification, concentration and collection aerosol device and operation method thereof

An aerosol, low temperature technology, applied in measurement devices, sampling, instruments, etc., can solve problems such as unfavorable analysis and detection, insufficient separation of solution and air flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

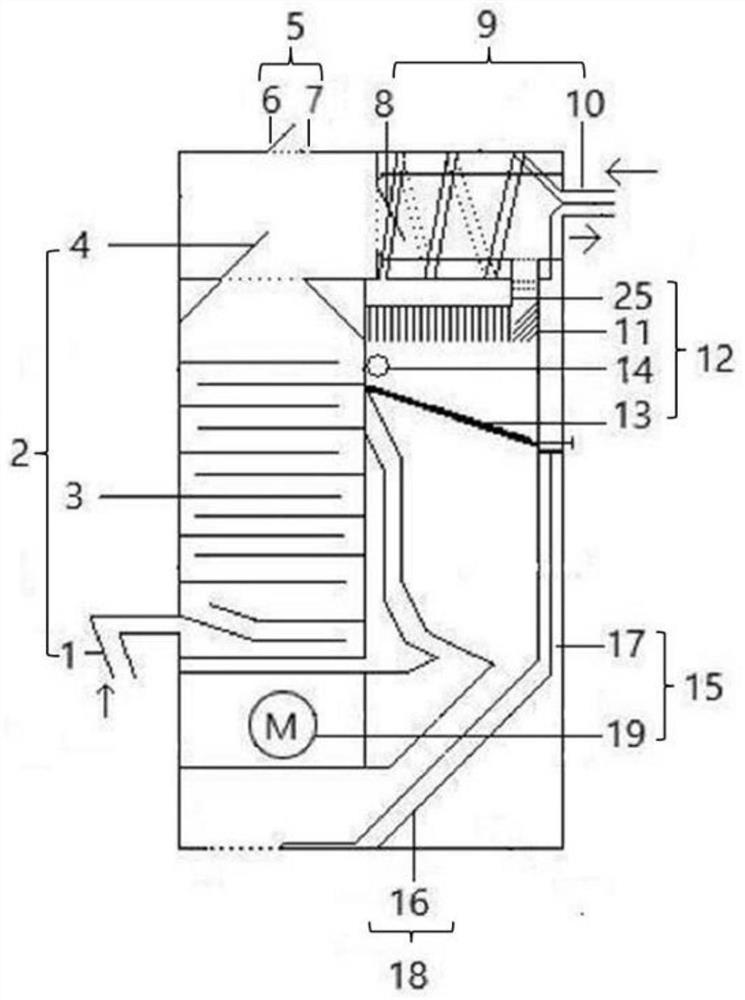

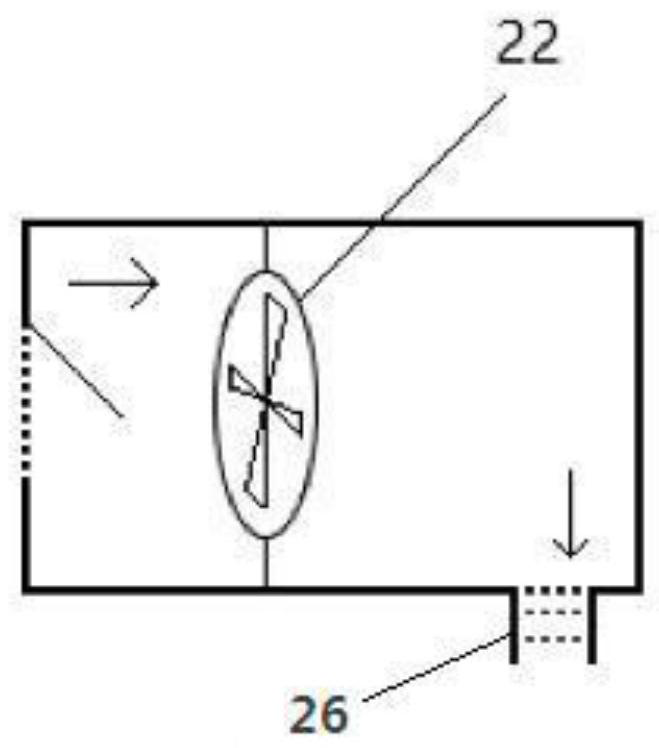

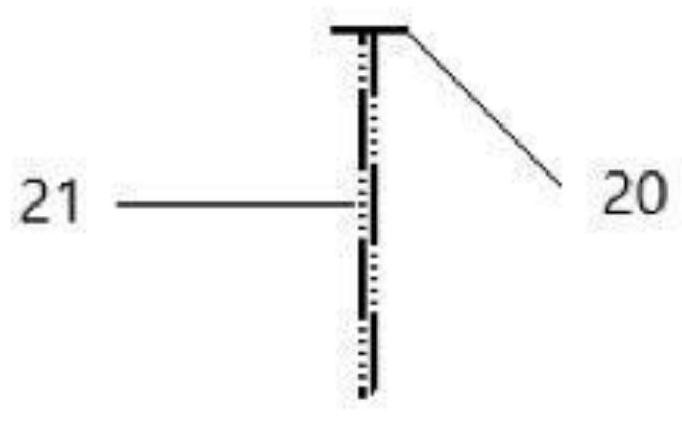

[0022] like figure 1 As shown, a low-temperature solidification concentration collection aerosol device includes a gas deceleration cabin 2, a gas retention cabin 5, an aerosol acceleration cabin 9, a gas humid heat flow atomization cabin 12, a gas freezing cabin 15 and a collection cabin 18. The gas stagnation chamber 5 is located above the gas deceleration chamber 2, the aerosol acceleration chamber 9 is horizontally adjacent to the gas deceleration chamber 5, and the gas humid heat flow atomization chamber 12, the gas freezing chamber 15 and the collection chamber 18 are located below the aerosol acceleration chamber 9 in sequence. The gas deceleration chamber 2 is used to reduce the kinetic energy of the incoming aerosol-containing airflow, so that it slowly enters the gas retention chamber 5 and stays therein. The gas retention chamber 5 concentrates the retained aerosol and then enters the aerosol acceleration chamber 9, which is accelerated by heating up. Increase the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com