Method for preparing high-molecular-weight nylon-46 in supercritical carbon dioxide

A carbon dioxide, high molecular weight technology, applied in the production of bulk chemicals, etc., can solve the problems of long post-solid-phase polycondensation reaction time, many operation procedures, and inability to achieve, and achieve the effects of environmental friendliness, simple operation steps, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

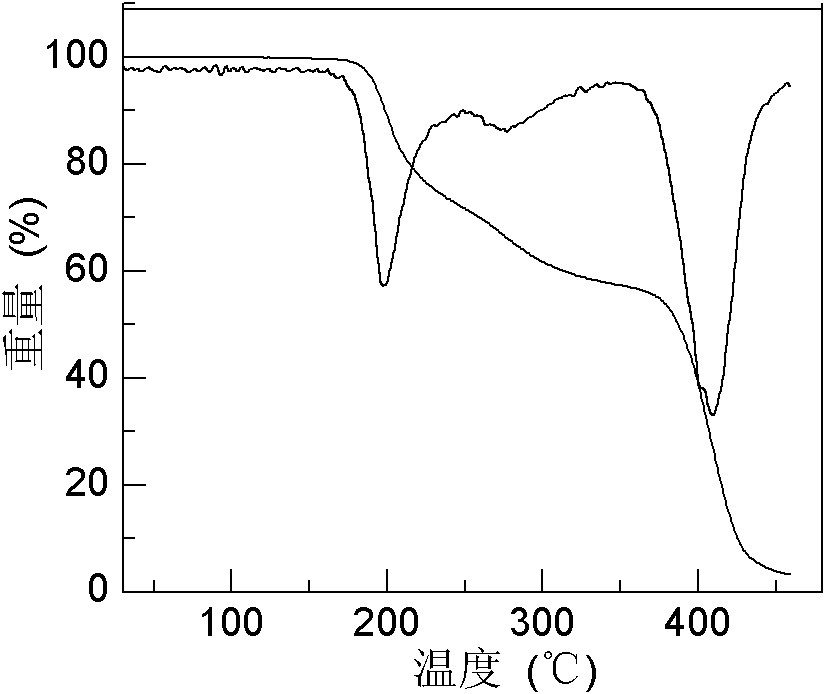

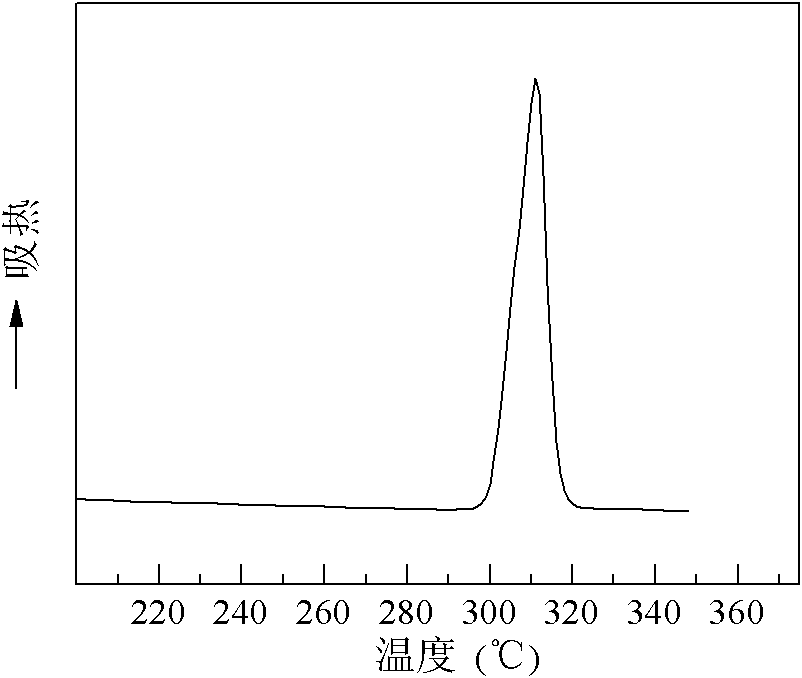

Image

Examples

Embodiment 1

[0045] Embodiment 1 has the preparation of the nylon-46 salt of different pH values

[0046] According to the molar ratio of 1,4-butanediamine to 1,6-adipic acid shown in Table 1, 1,4-butanediamine and 1,6-adipic acid were dissolved in absolute ethanol, respectively. Under stirring conditions, the ethanol solution of 1,4-butanediamine was added dropwise to the ethanol solution of 1,6-adipic acid, and precipitation occurred. After filtration, the white nylon 46 salt was obtained, which was dried under vacuum at 70°C.

[0047] Weigh the newly prepared nylon-46 salt, and make a solution with a mass concentration of 1% with distilled water. Use a pH meter (PHS-3C type) to measure the pH value of the solution. The pH values of nylon-46 salts prepared from different molar ratios (1,4-butanediamine / 1,6-adipic acid) are listed in Table 1.

[0048] Table 1 pH value of nylon-46 salt

[0049]

[0050] This table shows that with the increase of the added amount of 1,4-butanediami...

Embodiment 2

[0053] With the nylon-46 salt of the different pH values that example 1 prepares in SC-CO 2 Synthetic nylon-46.

[0054] Put the nylon-46 salt in the reactor and fill it with 99.9vol% high-purity CO 2 , exhaust the air in the kettle, vacuumize, replace the air in the kettle, and then pump in liquid CO 2 , until the pressure inside the kettle is 7MPa;

[0055] The reactor was heated to 190°C, the pressure inside the reactor was adjusted to 30MPa, and the precondensation reaction was carried out for 2 hours under this condition. After the reaction, remove the CO in the kettle 2 , re-pump liquid CO 2 .

[0056] The reaction kettle is heated to 280°C, and the pressure inside the kettle can reach 15MPa at this time. Under these conditions, the post-solid phase polycondensation reaction was carried out for 3h.

[0057] After the reaction was over, the pressure was released. Use a vacuum pump to depressurize, maintain the temperature in the kettle at 280°C to 270°C, and the...

Embodiment 3

[0064] The nylon-46 salt that is 7.26 with the pH value that example 1 prepares is in SC-CO 2 Synthetic nylon-46.

[0065] Put the nylon-46 salt in the reactor and fill it with 99.9vol% high-purity CO 2, exhaust the air in the kettle, vacuumize, replace the air in the kettle, and then pump in liquid CO 2 , until the pressure inside the kettle is 7MPa;

[0066] Heat the reactor to 180°C, adjust the pressure inside the reactor to 30MPa, and carry out the precondensation reaction for 2 hours under this condition. After the reaction, remove the CO in the kettle 2 , re-pump liquid CO 2 .

[0067] The reaction kettle is heated to 280°C, and the pressure inside the kettle can reach 15MPa at this time. Under these conditions, the post-solid phase polycondensation reaction was carried out for 3h.

[0068] After the reaction was over, the pressure was released. Use a vacuum pump to depressurize, maintain the temperature in the kettle at 280°C to 270°C, and the pressure in the ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com