Preparation method of hydrophobic alcohol metal compound and isosorbide modified polyester

A technology of metal compound and isosorbide, which is applied in the field of preparation of modified polyester, achieves the effect of small dosage, shortening the reaction time of esterification, and reducing the probability of side reactions in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

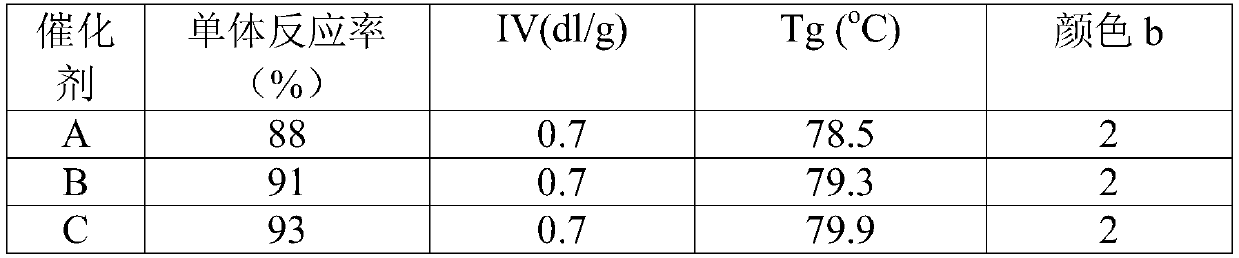

Examples

Embodiment 1

[0020] Catalyst A preparation

[0021] The preparation of described catalyst A can operate according to the following steps:

[0022] First, add 31.5g of BiCl to a 500mL three-neck flask under stirring 3 with 9.49gTiCl 4 (BiCl 3 with TiCl 4 The molar ratio is about 2:1) mix evenly, slowly add 19.53g of n-octanol under stirring, absorb the generated acid gas with lye, age at room temperature for 2 hours, after no gas is released, stir at 120°C for 3 hours, Catalyst A was prepared.

Embodiment 2

[0024] Catalyst B Preparation

[0025] The preparation method of catalyst B is the same as that of catalyst A in Example 1, except that the BiCl used 3 with TiCl 4 The molar ratio is about 1:1.

Embodiment 3

[0027] Catalyst C Preparation

[0028] The preparation method of catalyst C is the same as that of catalyst A in Example 1, except that the BiCl used 3 with TiCl 4 The molar ratio is about 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com