Cyclone separator, cyclone separation device and vacuum cleaner having cyclone separation device

A technology of cyclone separation device and cyclone separator, which is applied in the direction of vacuum cleaners, cyclone devices, and devices in which the axial direction of the cyclone can be reversed, etc., to achieve the effects of improved separation efficiency, high separation efficiency, and low power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

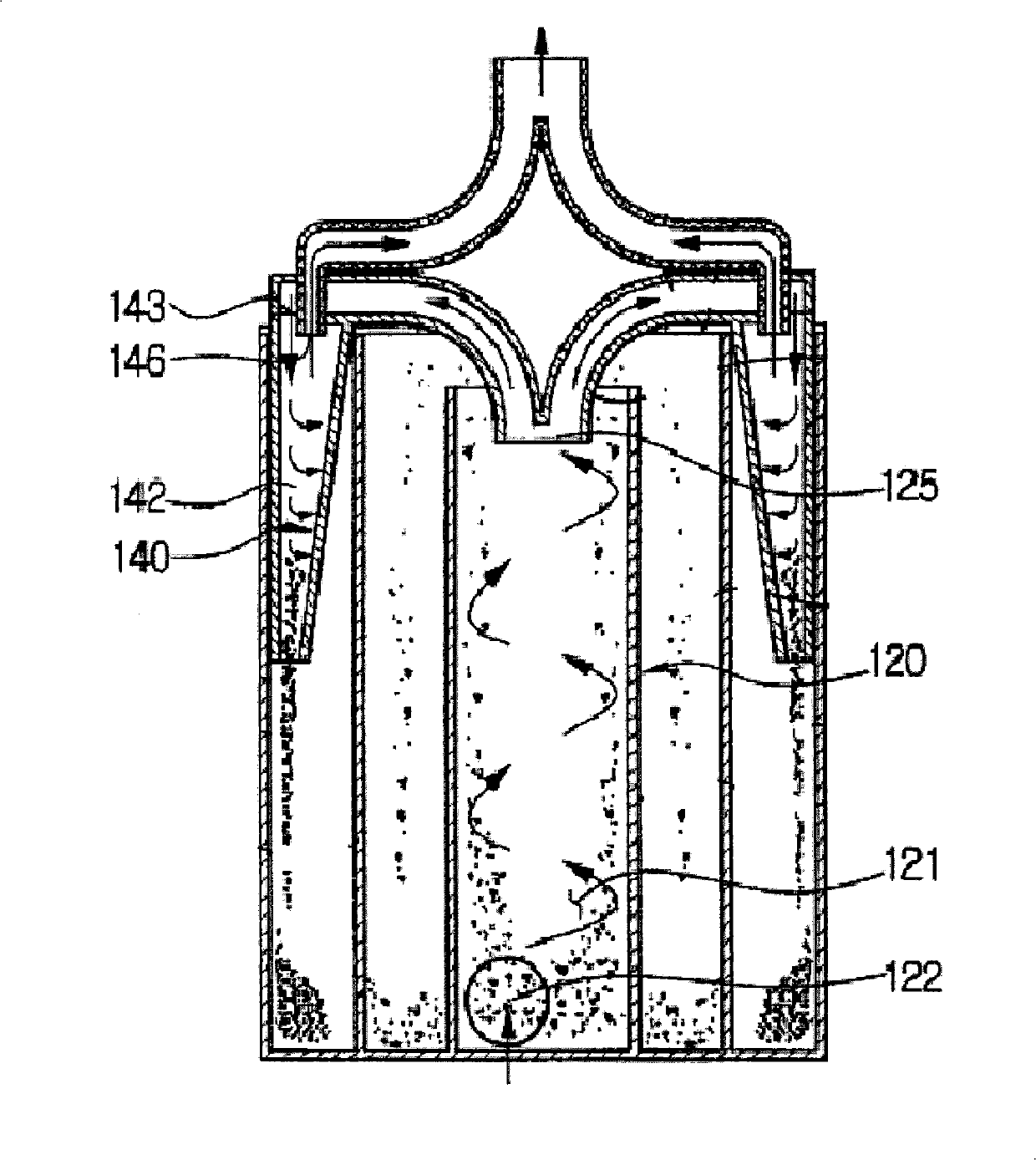

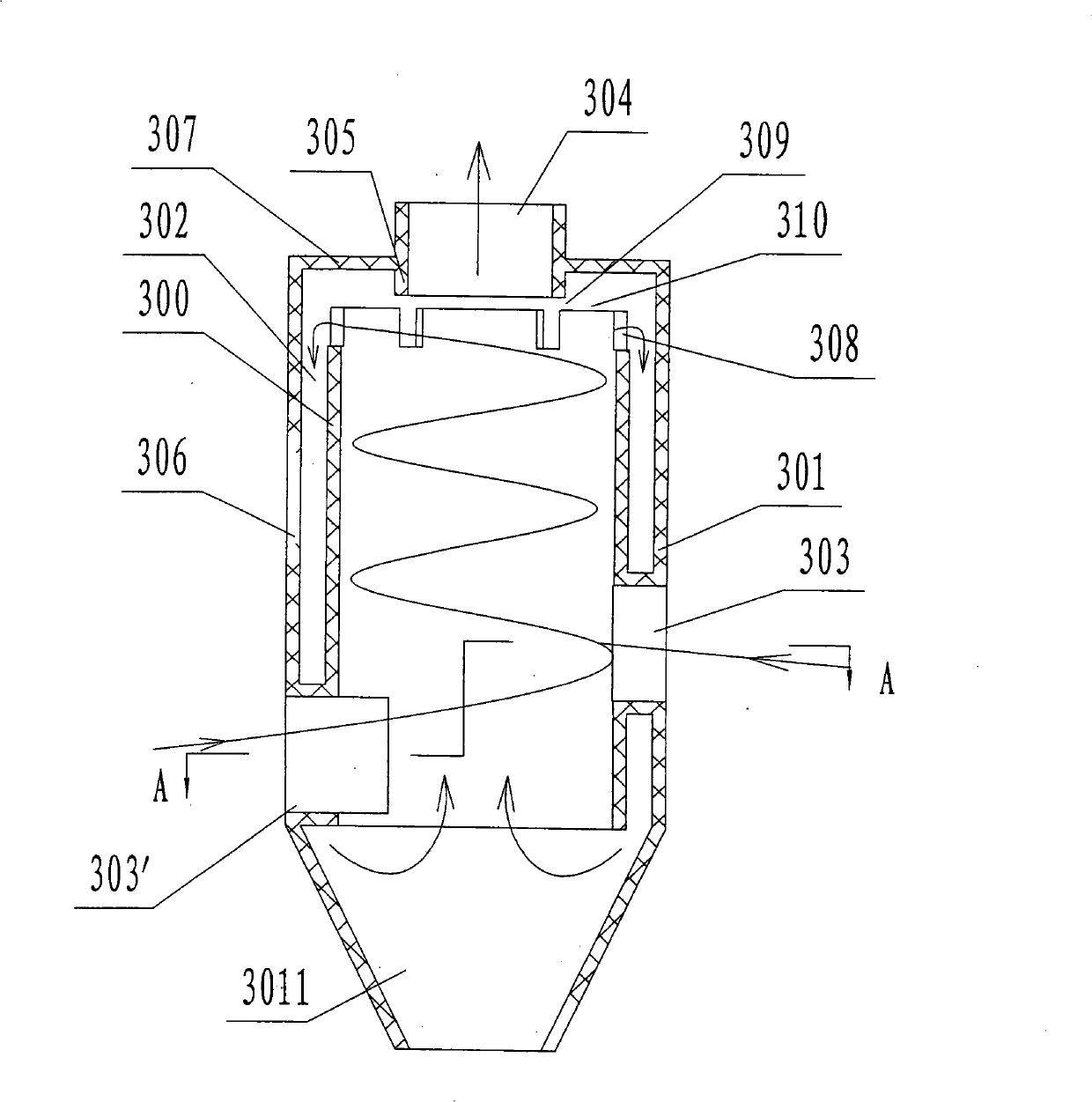

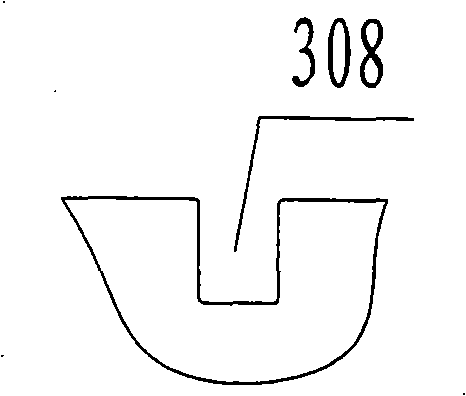

[0050] figure 2 It is the structural representation of the cyclone separator of the present invention, as figure 2 As shown, the present invention provides a cyclone separator, which comprises an inner cylinder 300 and an outer cylinder 301, an annular gap 302 is formed between the outer wall of the inner cylinder 300 and the inner wall of the outer cylinder 301, and the inner cylinder 300 The lower end of the outer cylinder 301 is an open end, the lower end of the outer cylinder 301 is closed, an air inlet 303 is set on the wall of the outer cylinder, an air outlet 304 is provided at the upper end of the outer cylinder 301, and a return section is provided between the upper end of the inner cylinder 300 and the air outlet 304 . The airflow enters the separator from the air inlet 303, part of the airflow after primary separation is discharged from the air outlet 304, and the other part is separated from the return part through the annular gap 302 for secondary separation, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com