High temperature resistant pi white label ink and preparation method thereof

A white label, high-temperature-resistant technology, applied in the field of ink, can solve the problems of no adhesion, poor ink printing performance, poor printing effect stability, etc., achieve excellent heat resistance and adhesion, avoid overall performance decline, overcome The effect of poor yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

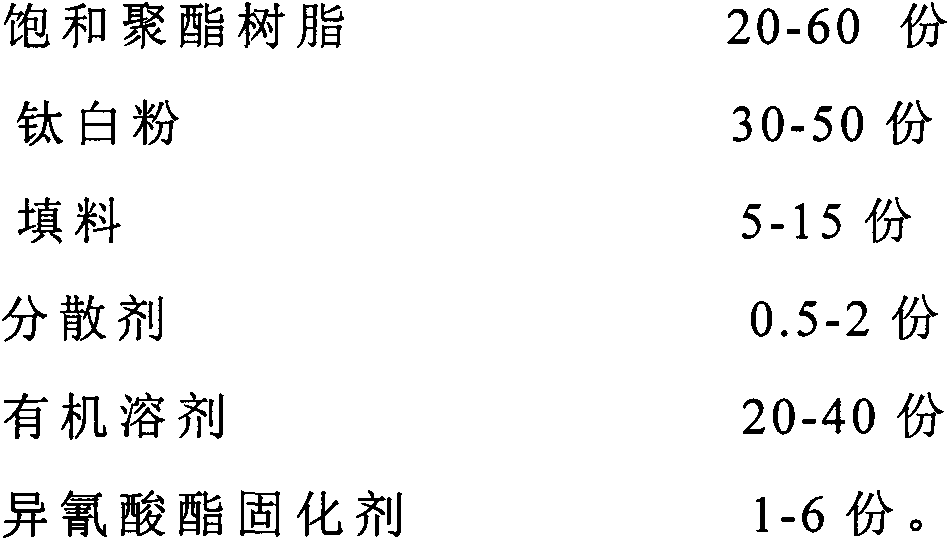

Method used

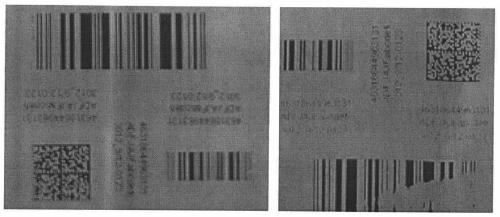

Image

Examples

Embodiment 1

[0040] In parts by weight, mix 20 parts of saturated polyester resin (ES-100), 10 parts of organic solvent and 0.5 part of dispersant, stir at 800 rpm for 10 minutes; then add 30 parts of titanium dioxide (U.S. DuPont), 5 parts of filler (1 part Kaolin, 2 parts of talcum powder, 2 parts of barium sulfate); 1500rpm stirred for 30 minutes to obtain the mixture; sand milled the mixture 6 times; then added 5 parts of solvent, dispersed for 10 minutes at 700rpm, and evenly obtained the main agent; added 2 1 part HDI curing agent, 10 parts solvent, and evenly dispersed to obtain high temperature resistant PI white label ink.

Embodiment 2

[0042] In parts by weight, mix 60 parts of saturated polyester resin (ES-320), 20 parts of organic solvent and 2 parts of dispersant, stir at 600 rpm for 10 minutes; then add 40 parts of titanium dioxide (U.S. DuPont), 8 parts of filler (2 parts Kaolin, 2 parts of talcum powder, 4 parts of barium sulfate); 1300rpm stirred for 30 minutes to obtain the mixture; sand milled the mixture 6 times; then added 15 parts of solvent, dispersed for 10 minutes at 800rpm, and evenly obtained the main agent; added 5 1 part HDI curing agent, 10 parts solvent, and evenly dispersed to obtain high temperature resistant PI white label ink.

Embodiment 3

[0044] In parts by weight, mix 40 parts of saturated polyester resin (ES-360), 13 parts of organic solvent and 0.9 part of dispersant, stir at 600 rpm for 10 minutes; then add 38 parts of titanium dioxide (U.S. DuPont), 11 parts of filler (5 parts Kaolin, 4 parts of talcum powder, 2 parts of barium sulfate); 1200rpm stirred for 30 minutes to obtain the mixture; sand milled the mixture 6 times; then added 6 parts of solvent, dispersed for 10 minutes at 600rpm, and evenly obtained the main agent; added 3 Part HDI curing agent, 13 parts solvent, after uniform dispersion, high temperature resistant PI white label ink can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com