A kind of environment-friendly PVC co-extruded color paint-free board and preparation method thereof

An environmentally friendly, paint-free board technology, applied in the field of plastic processing, can solve problems such as weld marks, hair spots, and hinder the fusion of PVC particles, achieve good hardness and thermal stability, clear and bright color, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

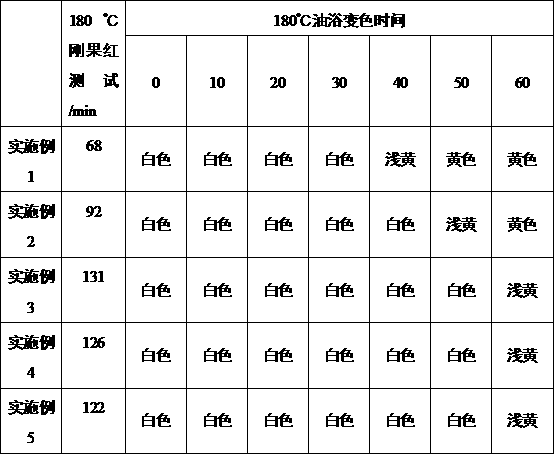

Embodiment 1

[0024] An environment-friendly PVC co-extrusion color paint-free board, including a PVC layer and a PVC foam layer, the PVC layer is prepared from the following raw materials in proportion by weight: 50 parts of PVC resin, 2.5 parts of composite calcium-zinc stabilizer, PVC inner 0.4 parts of lubricant G60, 0.2 parts of polyethylene wax, 25 parts of calcium carbonate, 3 parts of additive ACR, 1.5 parts of titanium dioxide, 2.5 parts of PVC masterbatch; PVC foam layer is prepared by the following raw materials in proportion by weight: PVC resin 75 parts, 4 parts of composite calcium zinc stabilizer, 0.6 parts of PVC internal lubricant G60, 0.4 parts of polyethylene wax, 50 parts of calcium carbonate, 6 parts of auxiliary agent ACR, 0.4 parts of oxidized polyethylene wax, 1 part of sodium bicarbonate, 2 parts of titanium dioxide share.

[0025] The preparation method of the above environment-friendly PVC co-extruded color paint-free board comprises the following steps:

[0026]...

Embodiment 2

[0031] An environment-friendly PVC co-extruded color paint-free board, including a PVC layer and a PVC foam layer, the PVC layer is prepared from the following raw materials in proportion by weight: 50 parts of PVC resin, 2.5 parts of composite calcium-zinc stabilizer, PVC inner 0.4 parts of lubricant G60, 0.2 parts of polyethylene wax, 20 parts of calcium carbonate, 3 parts of additive ACR, 1.5 parts of titanium dioxide, 1 part of glass fiber, 0.8 parts of wood fiber, 2 parts of calcium hydrogen phosphate, 3 parts of white carbon black, rare earth stabilizer 0.5 parts of PVC masterbatch, 2.5 parts of PVC color masterbatch; PVC foam layer is prepared from the following raw materials according to weight ratio: 75 parts of PVC resin, 4 parts of composite calcium zinc stabilizer, 0.6 parts of PVC internal lubricant G60, polyethylene wax 0.4 parts, 45 parts of calcium carbonate, 6 parts of additive ACR, 0.4 parts of oxidized polyethylene wax, 1 part of sodium bicarbonate, 2 parts o...

Embodiment 3

[0038] An environment-friendly PVC co-extruded color paint-free board, including a PVC layer and a PVC foam layer, the PVC layer is prepared from the following raw materials in proportion by weight: 50 parts of PVC resin, 2.5 parts of composite calcium-zinc stabilizer, PVC inner 0.4 parts of lubricant G60, 0.2 parts of polyethylene wax, 20 parts of calcium carbonate, 3 parts of additive ACR, 1.5 parts of titanium dioxide, 1 part of glass fiber, 0.8 parts of wood fiber, 2 parts of calcium hydrogen phosphate, 3 parts of white carbon black, rare earth stabilizer 0.5 parts of PVC masterbatch, 2.5 parts of PVC color masterbatch; PVC foam layer is prepared from the following raw materials according to weight ratio: 75 parts of PVC resin, 4 parts of composite calcium zinc stabilizer, 0.6 parts of PVC internal lubricant G60, polyethylene wax 0.4 parts, 45 parts of calcium carbonate, 6 parts of additive ACR, 0.4 parts of oxidized polyethylene wax, 1 part of sodium bicarbonate, 2 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com