High-altitude sounding platform for spacecraft final assembly

A technology for spacecraft assembly and operating platforms, applied in the direction of lifting devices, etc., can solve problems such as insufficient exploration, insufficient safety and stability of high-altitude operations, and achieve the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The high-altitude exploration and extension work platform for spacecraft assembly of the present invention will be further described below in conjunction with the accompanying drawings. This description is only exemplary and is not intended to limit the protection scope of the present invention.

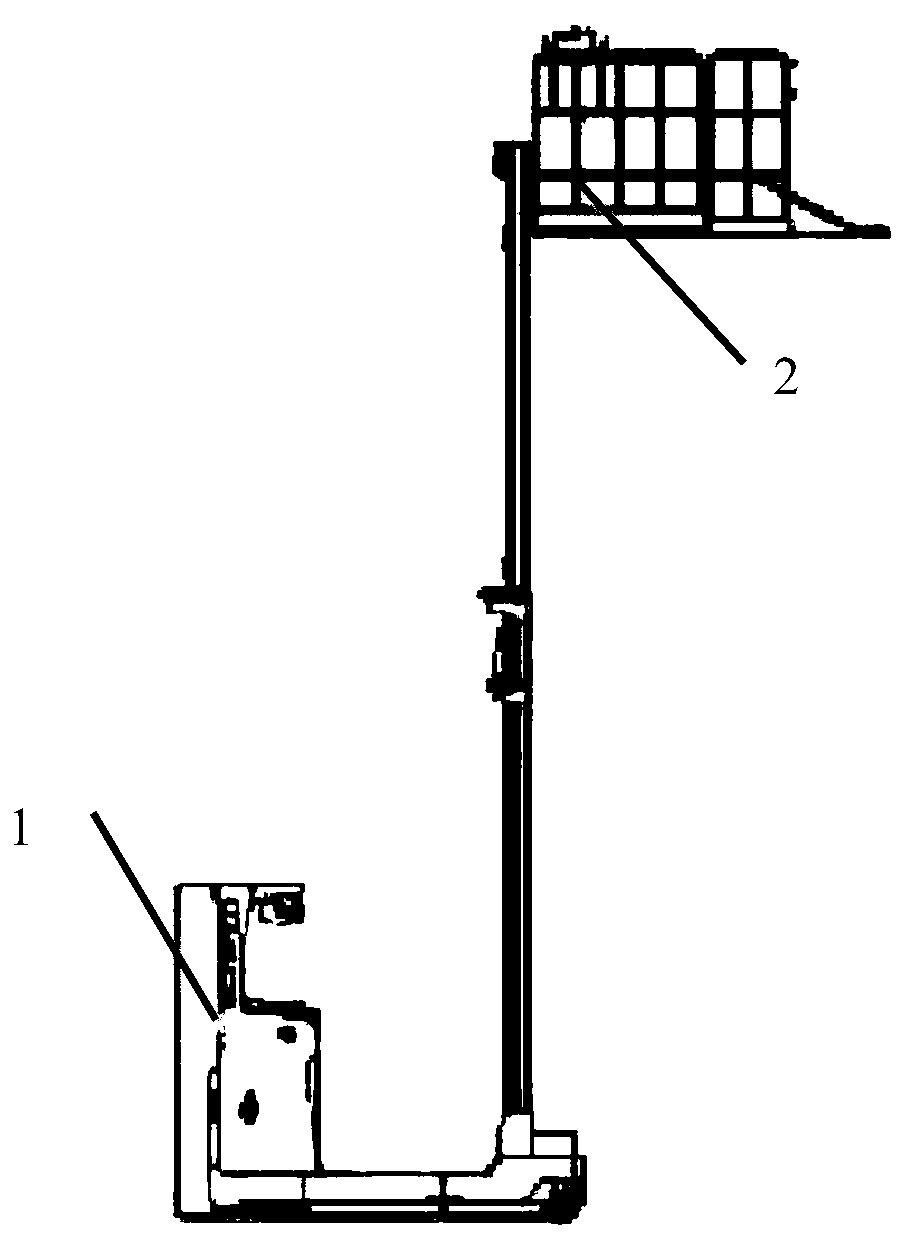

[0036] The high-altitude exploration and extension operation platform adopts the form of a modified electric forward-moving forklift, and an adjustable operating platform is added to the fork of the forklift mast. It is the combination of "reach truck" and "operating platform", such as figure 1 shown.

[0037] The reach truck is an electric reach truck commonly used in various fields, and the fork is the standard product of the forklift.

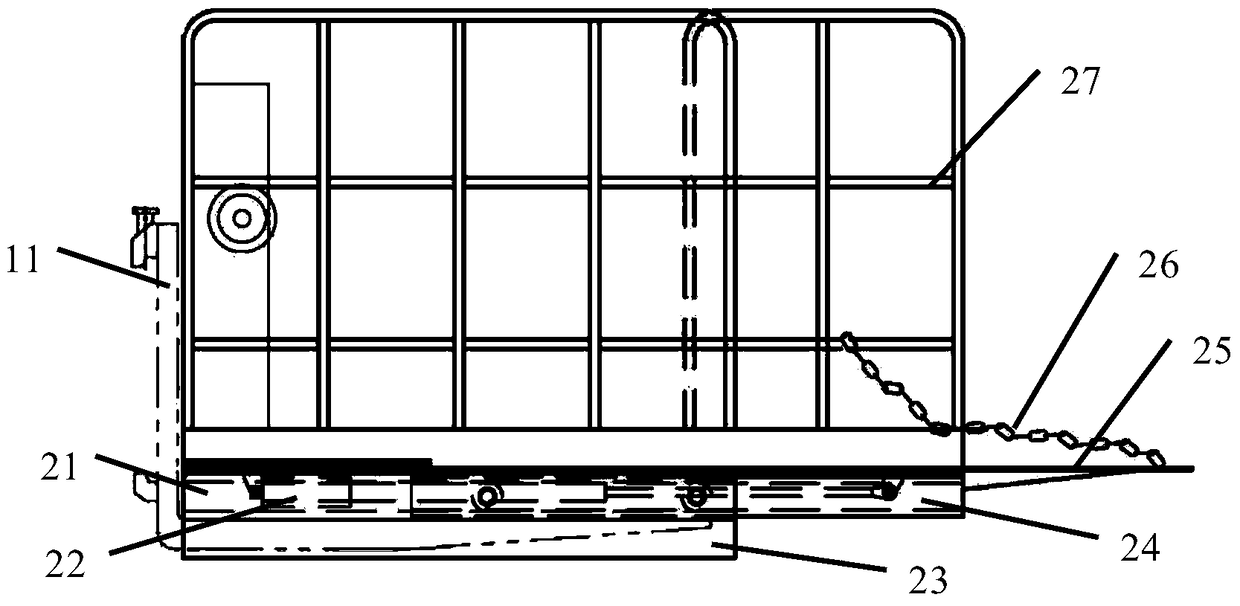

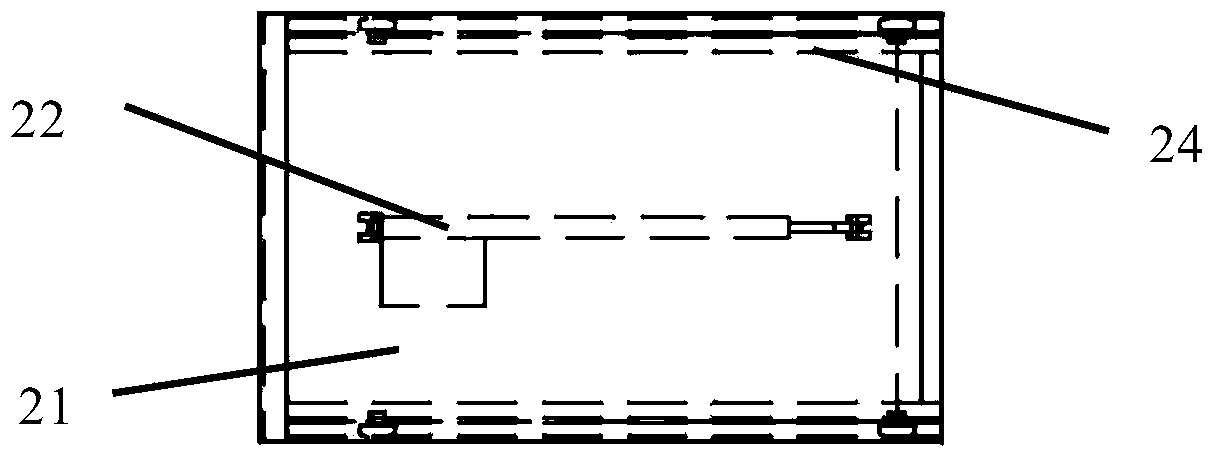

[0038] Such as figure 2 As shown, the operating platform is mainly composed of a fixed platform, a movable platform, a front baffle, a fork cover, a guardrail, and an electric push rod. Among them, the fixed platform, the movable platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com