Method for connecting metal material with resin matrix composite material via friction stir welding

A technology of friction stir welding and metal materials, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of pre-processing and stress concentration, low bonding strength, thermal deformation, etc., and achieve fast connection speed and automation High degree, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

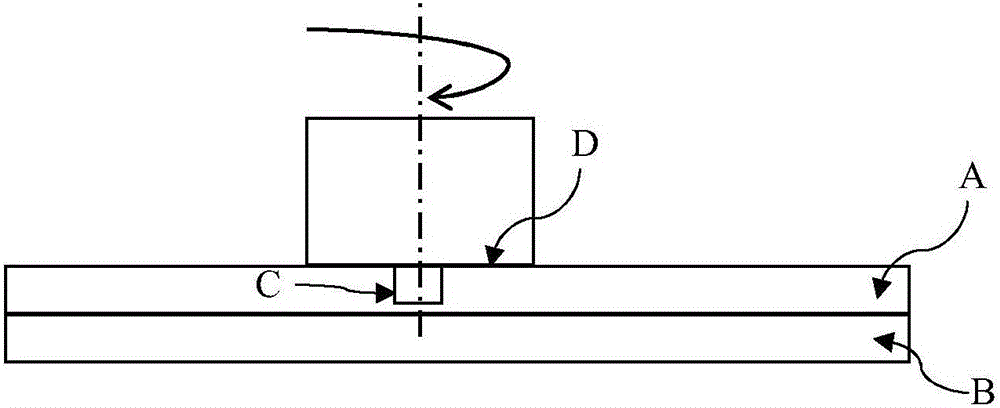

[0030] Implementation Option 1: Combining figure 1 Explain that this embodiment is accomplished through the following steps:

[0031] Step 1: Clean the metal material A and the resin-based composite material B with a thickness of 2.0mm with alcohol, stack the metal material A on the resin-based composite material B, and then fix the two on the workbench with a clamp.

[0032] Step 2: Control the tool stirring head C rotating at high speed to insert the metal material A and not contact the surface of the resin-based composite material B. Under the joint action of the friction heat generated by the tool stirring head C and the pressing pressure of the tool shoulder D, the metal material Direct connection between A and resin-based composite B. Wherein the diameter of the stirring head is 2.0 mm, and the diameter of the tool shoulder is 20 mm.

[0033] Step 3: Set the process parameters of friction stir welding, the tool speed is 1000rpm, the inclination angle is 0° when the to...

Embodiment approach 2

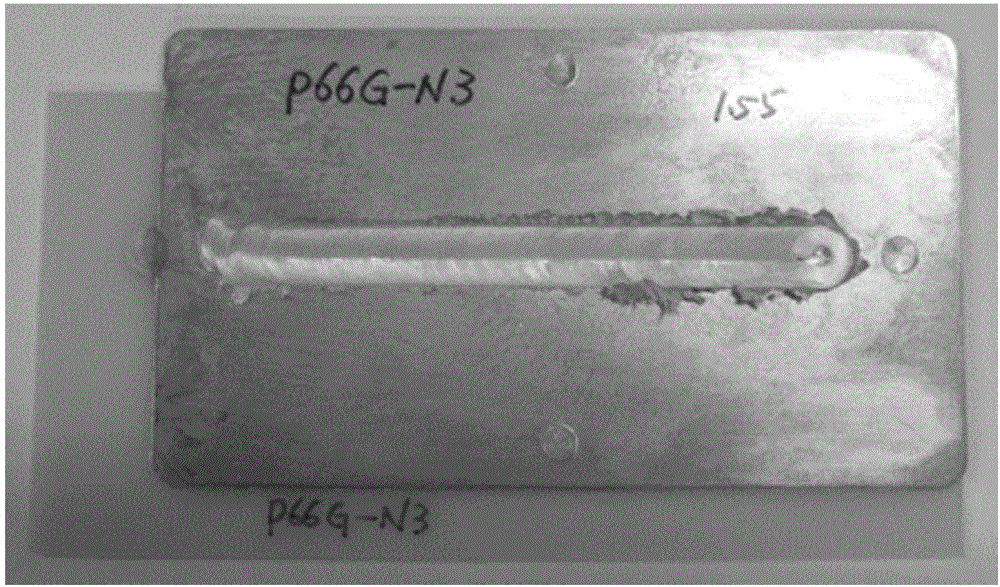

[0035] Set the rotation speed of the tool to 2000rpm, the welding speed to 100mm / min, the inclination angle of the tool to 2° when the tool advances, and the insertion and holding time of the stirring head to 5 seconds, and the others are the same as in the first embodiment. The operation command is input through the CNC machine tool to automatically complete the linear lap welding between the two materials; after the welding is completed, it is fully cooled to obtain the metal material / resin material connection.

Embodiment approach 3

[0037] The rotational speed of the tool is set to 4000rpm, the welding speed is 1000mm / min, the inclination angle of the tool is 2° when the tool advances, the insertion and holding time of the stirring head is 2 seconds, and the others are the same as the second embodiment. The operation command is input through the CNC machine tool to automatically complete the linear lap welding between the two materials; after the welding is completed, it is fully cooled to obtain the metal material / resin material connection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com