Ultrasonic wave method filter membrane attached particulate matter re-flying method and device

An ultrasonic method and particle technology, applied in the direction of measuring devices, sampling devices, test sample preparation, etc., can solve the problems of low stripping efficiency and difficult operation, and achieve easy control of atomized particle size, strong penetrability, and direct The effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further illustrated by the following examples.

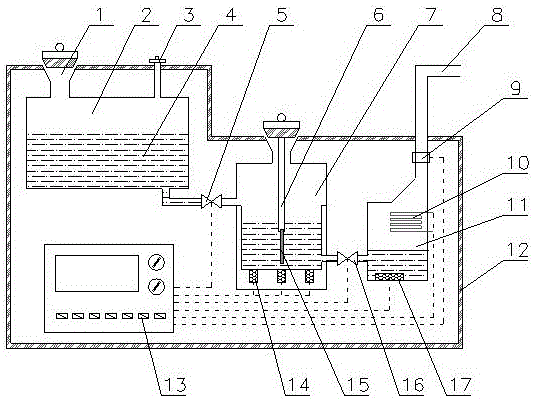

[0020] The method for attaching particulate matter to the ultrasonic filter membrane of the present invention mainly includes the following steps:

[0021] (1) Immerse the filter membrane with attached particles in the cleaning solution;

[0022] (2) Use the high-frequency oscillation effect of ultrasonic to peel, stir and disperse the particulate matter attached to the filter membrane in the cleaning solution;

[0023] (3) Use the ultrasonic fountain to form a mist to disperse and suspend the cleaning liquid containing particles to form a liquid mist containing particles;

[0024] (4) Heating the suspension mist containing particulate matter, the particulate matter inside the mist is released as the vaporization of the liquid mist disappears, and is in a suspended state. At the same time, the vaporization of the liquid mist will form an expanded airflow to achieve suspended particulate matter Fly out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com