Manufacturing method of high-density pure-rhenium test tube

A manufacturing method and high-density technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of difficult to use cold isostatic pressing, scarce rhenium resources, poor fluidity, etc., to improve material utilization, improve charging Uniformity, the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

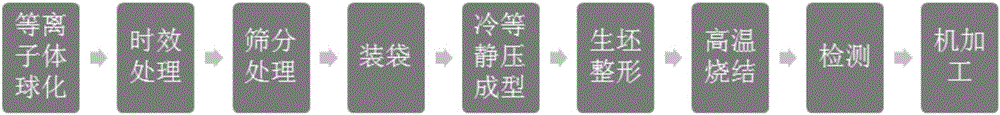

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of manufacture method of high-density rhenium test tube

[0036] Including the following steps:

[0037] 1) Plasma spheroidization: choose rhenium powder with a purity of 99.99% and a Fischer particle size of 3 μm, and carry out radio frequency plasma spheroidization on the rhenium powder. The main process parameters of the spheroidization are: input power 55KW, argon working gas flow rate 35slpm , the argon shielding gas flow rate is 75slpm, the system pressure is 1500Pa, the powder feeding rate is 30g / min, the Fischer particle size after spheroidization is 5.5μm, and the oxygen content is 0.048wt%;

[0038] 2) Aging treatment: aging treatment is carried out on the spheroidized rhenium powder under the condition of vacuum protection, the aging temperature is 800 ℃, after 4 hours of heat preservation, it is cooled with the furnace, and the vacuum degree at high temperature is not lower than 1×10 -2 Pa;

[0039] 3) sieving treatment; use 300 mesh si...

Embodiment 2

[0047] Embodiment 2 A kind of manufacture method of high-density rhenium test tube

[0048] Including the following steps:

[0049] 1) Plasma spheroidization: choose rhenium powder with a purity of 99.99% and a Fischer particle size of 8 μm, and carry out radio frequency plasma spheroidization on the rhenium powder. The main process parameters of the spheroidization are: input power 75KW, argon gas flow rate 55slpm , the argon shielding gas flow rate is 85slpm, the system pressure is 1500Pa, the powder feeding rate is 15g / min, the Fischer particle size after spheroidization is 12μm, and the oxygen content is 0.046wt%;

[0050] 2) Aging treatment: aging treatment is carried out on the spheroidized rhenium powder under the condition of vacuum protection, the aging temperature is 800 ℃, after 4 hours of heat preservation, it is cooled with the furnace, and the vacuum degree at high temperature is not lower than 1×10 -2 Pa;

[0051] 3) sieving treatment; the rhenium powder after...

Embodiment 3

[0058] Embodiment 3 A kind of manufacturing method of high-density rhenium test tube

[0059] Including the following steps:

[0060] 1) Plasma spheroidization: choose rhenium powder with a purity of 99.99% and a Fischer particle size of 5 μm, and perform radio frequency plasma spheroidization on the rhenium powder. The main process parameters of the spheroidization are: input power 65KW, argon gas flow rate 45slpm , the flow rate of argon shielding gas is 65slpm, the system pressure is 1500Pa, the powder feeding rate is 20g / min, the Fischer particle size after spheroidization is 8μm, and the oxygen content is 0.045wt%;

[0061] 2) Aging treatment: aging treatment is carried out on the spheroidized rhenium powder under the condition of vacuum protection, the aging temperature is 800 ℃, after 4 hours of heat preservation, it is cooled with the furnace, and the vacuum degree at high temperature is not lower than 1*10 -2 Pa;

[0062] 3) sieving treatment; the rhenium powder aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com