Catalyst carrier, preparation method thereof and hydrodemetalation catalyst

A catalyst carrier, hydrodemetallization technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex preparation process additives, insufficient permeability and/or metal capacity, pores The quality is not good enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The method for preparing the catalyst carrier of the present invention further includes cooling the mixture obtained from the hydrothermal treatment to room temperature after the hydrothermal treatment and before solid-liquid separation. The room temperature in the present invention means that the temperature is not subject to special testing and control, and it only needs to be roughly similar to the ambient temperature, generally 10-40°C.

[0037] Preferably, the method for preparing the catalyst carrier of the present invention further includes adding additives before the hydrothermal treatment, so as to further improve the performance of the catalyst carrier. The adding time of the auxiliary agent is not particularly limited, it can be added before or during the mixing reaction of the alkali and the aluminum salt, and can also be added after the gelatinous liquid is obtained. The type of the auxiliary agent is not particularly limited. Preferably, the auxiliary agen...

Embodiment approach

[0041] In the present invention, the preparation method of the hydrodemetallization catalyst is not particularly limited, and conventional preparation methods in the art can be used. According to a specific embodiment of the present invention, the preparation method of the hydrodemetallization catalyst may include the following steps: (1) Dissolving the nickel source and the molybdenum source in deionized water to obtain a nickel-molybdenum mixed solution, the nickel-molybdenum mixed solution The content of nickel as NiO is 2-4% by weight, and as MoO 3 The calculated molybdenum content is 5-7% by weight; (2) at room temperature, the nickel-molybdenum mixed solution is impregnated with the catalyst carrier of the present invention by an equal-volume impregnation method and kept for 8-16 hours to obtain a precursor; (3) The precursor obtained in step (2) is dried in an oven at 70-90° C. for 8-16 hours, and then calcined at 400-600° C. for 3-6 hours. Wherein, the nickel source c...

Embodiment 1

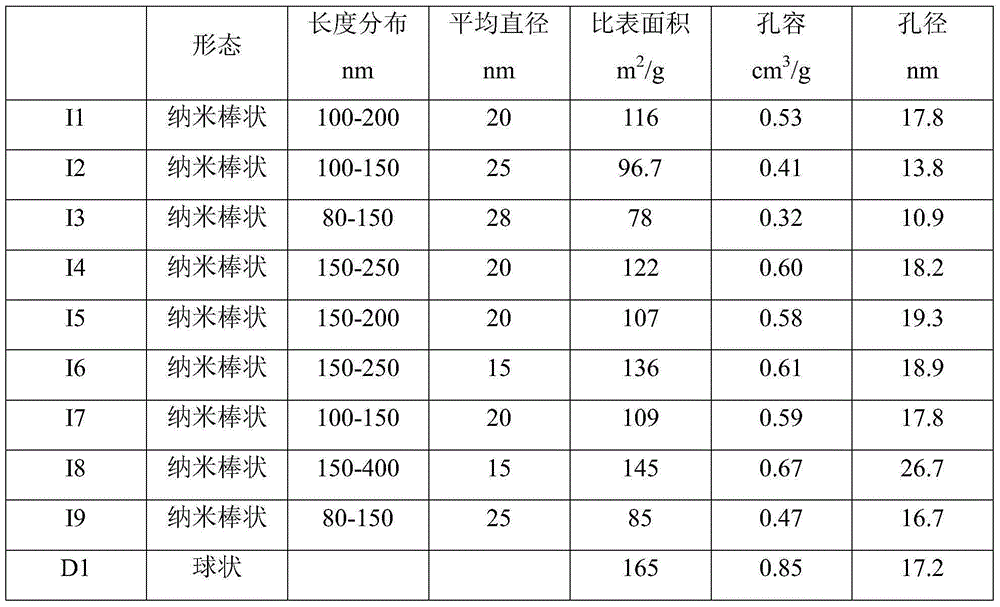

[0046] An aqueous aluminum chloride solution with a concentration of 2M and an aqueous ammonia solution with a concentration of 1M were prepared, and the ammonia solution was added dropwise into the aqueous aluminum chloride solution, so that the pH of the obtained milky white colloidal liquid was 4.5. The resulting gelatinous liquid was transferred to a hydrothermal kettle, placed in an oven, heated to 160°C and kept for 24 hours, and then naturally cooled to room temperature. The reacted product was separated by centrifugation, washed repeatedly with deionized water, and then dried in an oven at 120° C. for 12 hours to obtain a pseudo-boehmite precursor. The obtained precursor was heated to 550°C in the air for 2 hours, and then the obtained solid and peptizer (15% nitric acid) were mixed in a weight ratio of 100:2 and then extruded to obtain the catalyst carrier I1, the properties of which are shown in the table 1.

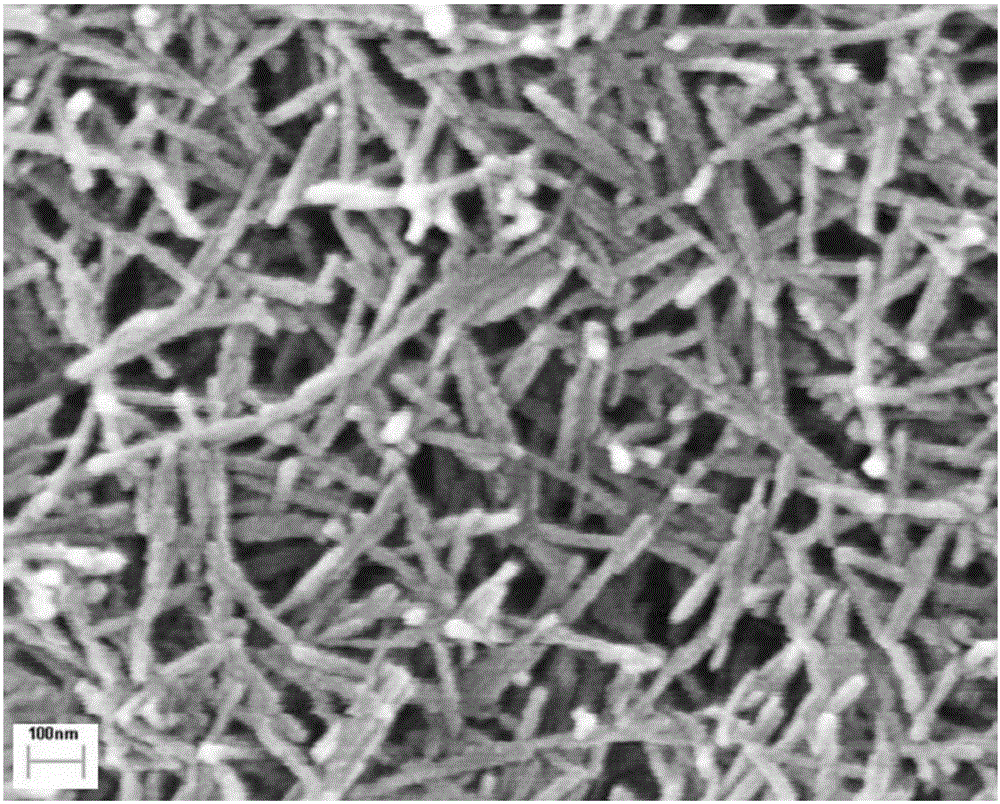

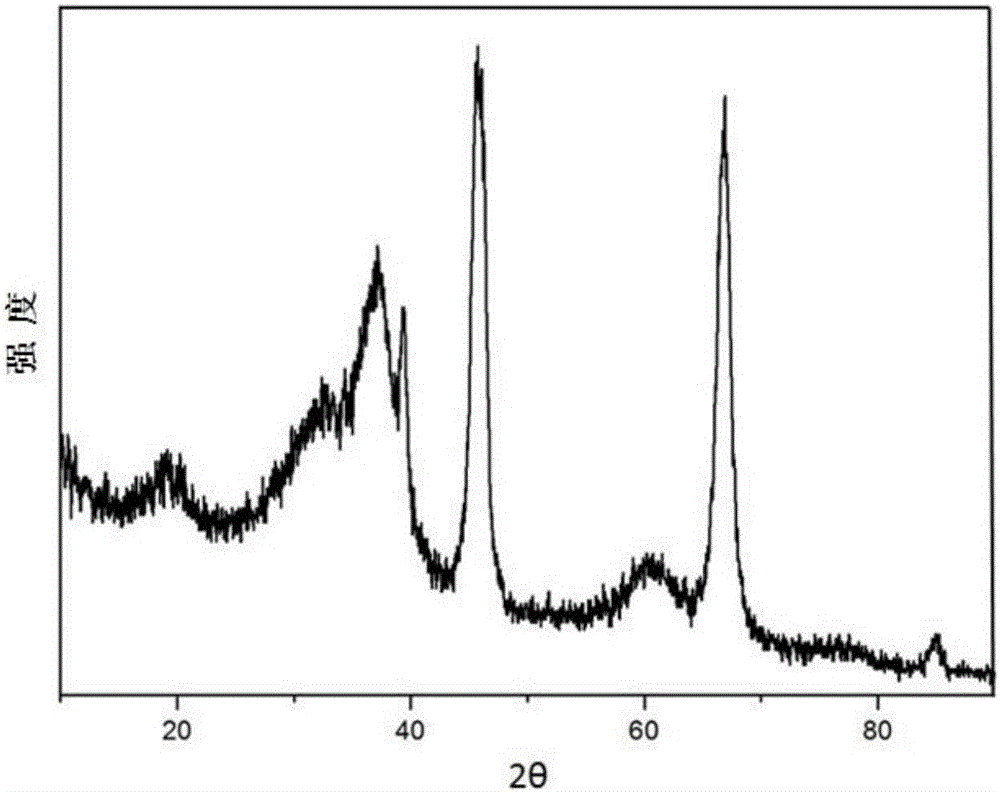

[0047] Carry out SEM detection to I1, the obtained resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com